Interface solutions support the thriving and growing global blue economy by providing sensor technologies for exploration, research, energy production, sustainability, transport, and aquaculture activities.

Oceans cover about 70% of the planet’s surface and would be the seventh largest economy in the world if it were a country. The blue economy emphasizes the economic potential of the ocean and other coastal resources, along with addressing other environmental long-term benefits.

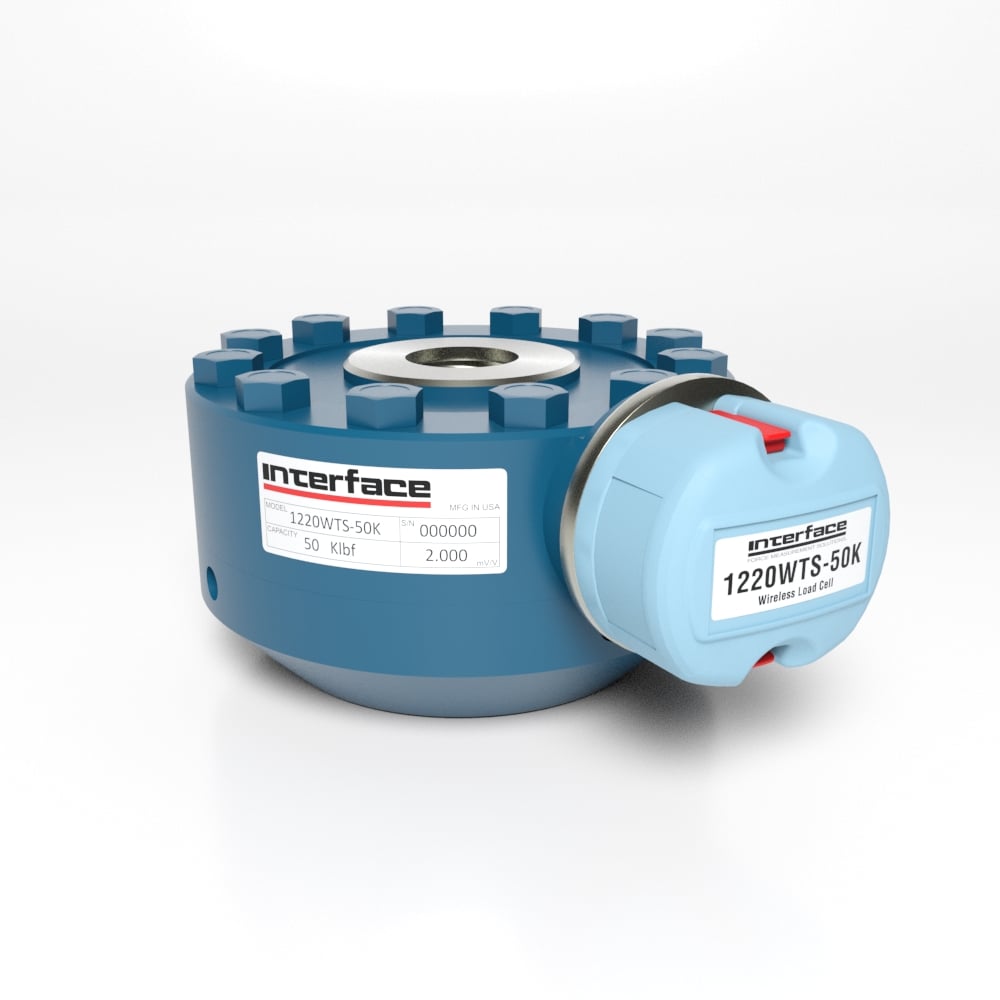

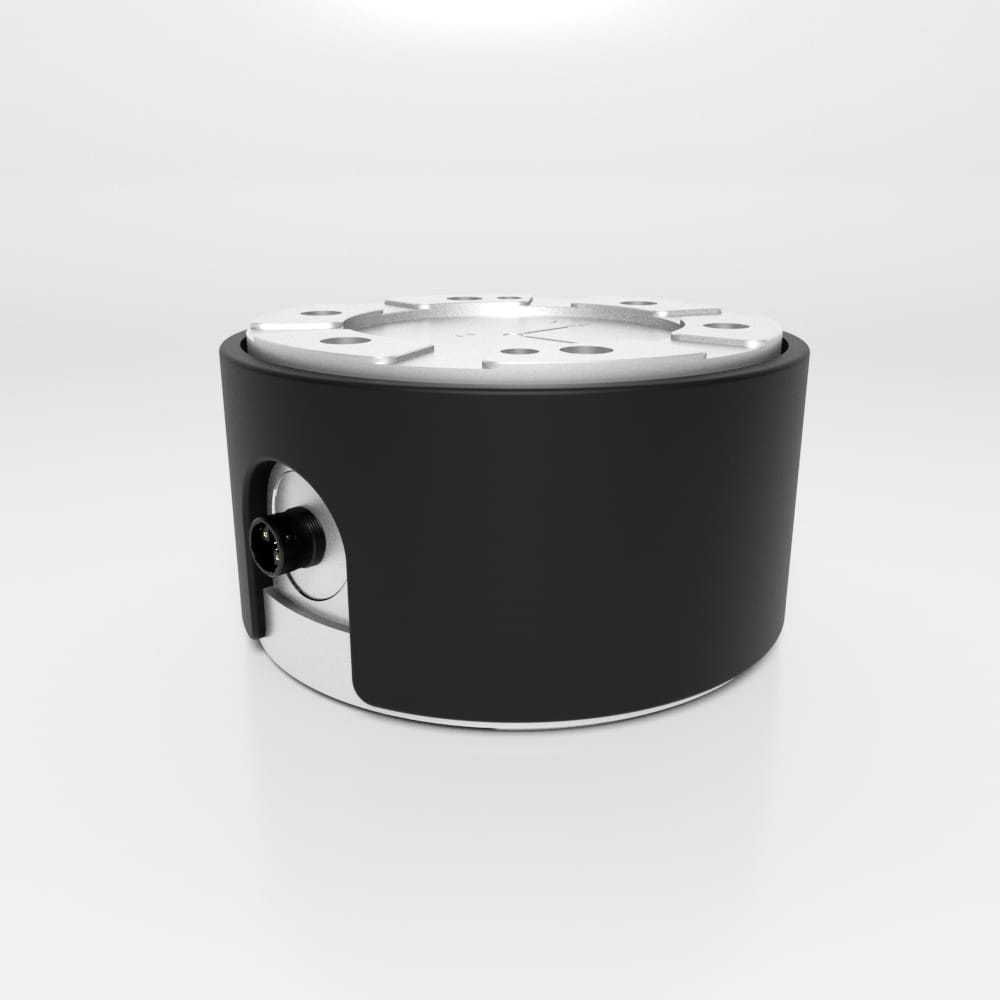

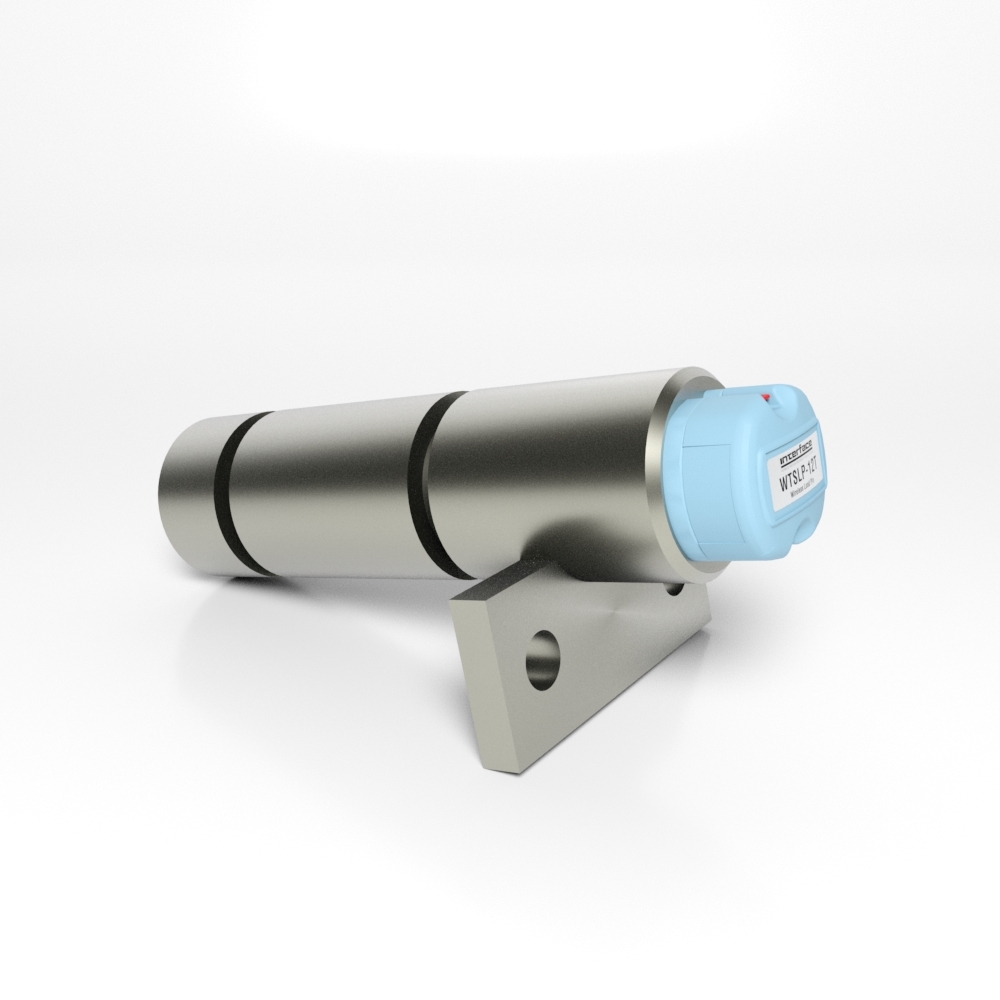

Interface understands that maritime applications are some of the most complex because they require specially designed test and measurement equipment to handle the often-harsh environments in testing, monitoring, and ongoing operational use. This includes our line of products, such as our stainless steel, sealed, ATEX-certified, and submersible load cells, load pins, shackles, tension links, and wireless telemetry solutions.

Interface’s submersible and environmentally protected load cells and instrumentation can be used in various aspects of the blue economy, including applications in fisheries, cargo handling and shipping, mining, aquacultural monitoring, and offshore renewable energy.

Blue Economy Applications Using Interface Products:

- Anchoring Systems for Offshore Structures

- Fishery Operations

- Maritime Cargo Handling and Shipping

- Aquaculture Monitoring and Feeding Systems

- Underwater Vehicles and Robotics

- Offshore Hydro and Tidal Renewable Energy Production

- Offshore Wind Farm Installation and Maintenance

- Harbors and Ports Equipment for Lifting and Weighing

- Near-Shore Infrastructure Monitoring

- Oceanographic Research

- Underwater Construction

- Habitat Restoration

- Fishing Gear Monitoring and Optimization

- Marine Salvage and Recovery Operations

- Offshore Oil and Gas Platform Monitoring

The blue economy refers to creating ecological uses of the ocean’s resources to protect the marine life that dwells deep and have us land dwellers become a part of preserving the ocean’s ecosystem.

Interface Blue Economy Capabilities and Solutions

- Stainless steel and rugged load cell designs made for extreme temperatures and climates

- Environmentally sealed products used in submersible environments

- Bluetooth and wireless data acquisition and instrumentation for safety monitoring

- Custom solutions based on safety and regulatory specifications

- Customized load pin, load shackles, and tension links for hoist and lifting applications

Our Interface expert engineers can help design customizable solutions for blue economy applications using our products designed for offshore, underwater, and splash zone locations.

BlueEconomy_Infographic