Fitness Equipment

Fitness Equipment

Fitness equipment manufacturers are installing sensors of all types into their equipment to measure various forces and provide fitness data to the user, trainers, physical therapists, and doctors to monitor movement and actions.

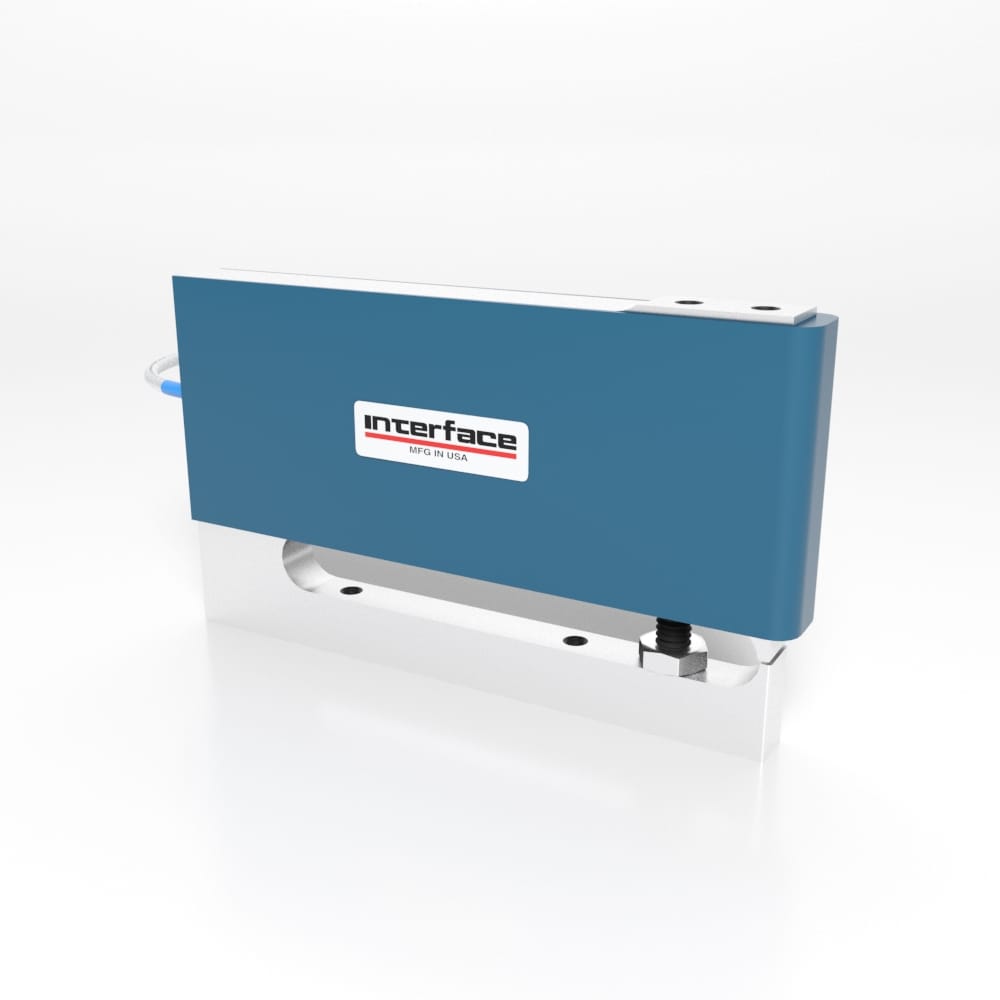

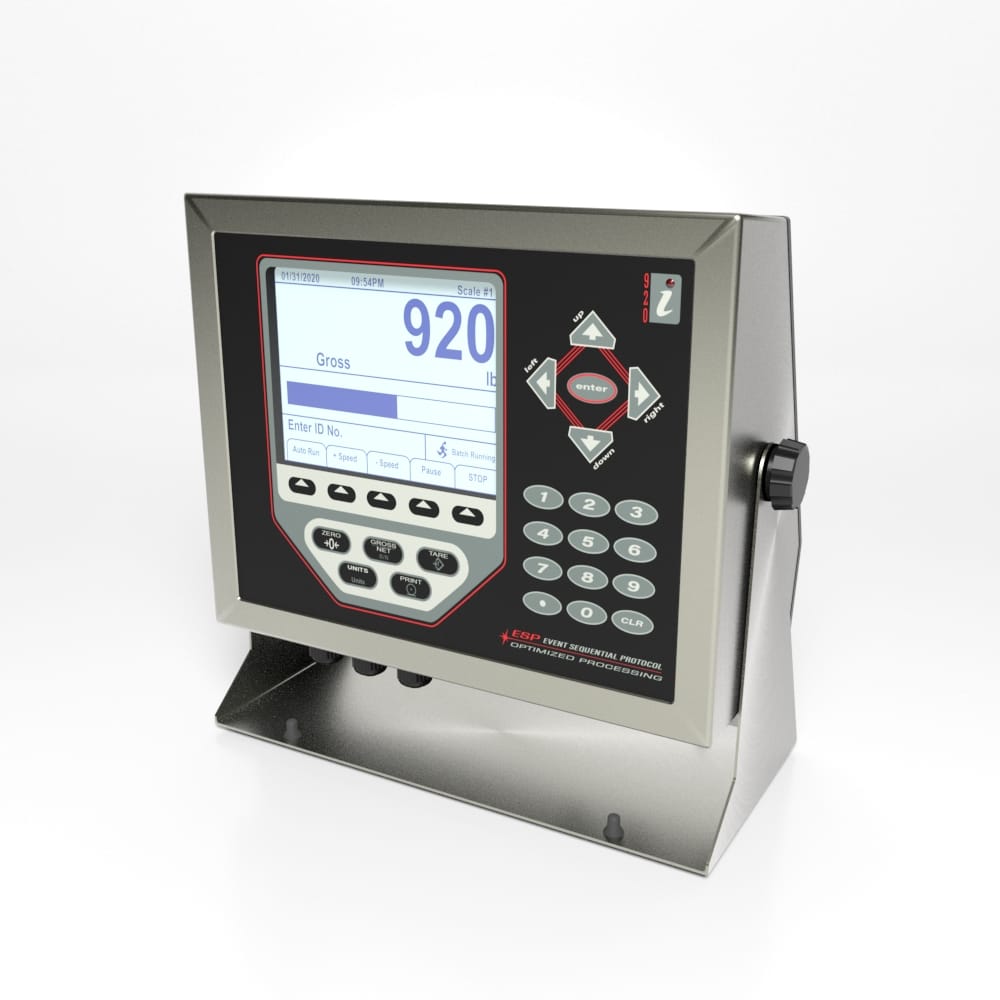

Interface’s load cells, torque transducers, multi-axis sensor and instrumentation are currently utilized in the testing, production, and continuous monitoring of modern exercise equipment. Demand for instantaneous feedback by consumers is part of the requirement sensor-based systems that accurately measure weight, torque, and force in motion.

Interface Mini Load Cells are designed for easy integration into fitness equipment, for all phases from R&D to consumer use. The size, capacity and low cost provides a sensible OEM option to activate the equipment for real-time feedback and performance monitoring. The results are increased use, higher satisfaction by the user, accuracy in measurement, better feedback, increased quality, and enhanced safety features.

Types of Fitness Equipment Benefitting from Interface Measurement Solutions

The global fitness market requires a trusted and proven measurement solutions partner. The industry is looking at consistent growth over the next few years. The global fitness equipment market is estimated to be over $16B and growing at 5.3% CAGR from 2023 to 2030.

Interface load cells are being used to assess different running techniques and monitor the progress of rehabilitation exercise. Interface’s sensors provide accurate data for all types of user profiles in the fitness industry such as strength variability, weights, and distinct experience levels.

Fitness_Infographic_Poster

Water Bottle Dispensing and Weighing

Water Bottle Dispensing and Weighing