From construction and manufacturing to logistics and healthcare, the importance of efficient and secure lifting operations cannot be overstated. Embracing sensor technologies is crucial in achieving optimal results.

In recent years, cutting-edge equipment using force sensor technologies has sparked a revolution in the field of lifting solutions, empowering operators, manufacturers and equipment designers with unprecedented precision and control. By seamlessly integrating force sensors into lifting equipment like cranes, hoists, robotics and machines, industries possess the ability to accurately measure and monitor the forces exerted during every lifting operation, elevating productivity and ensuring the highest levels of safety.

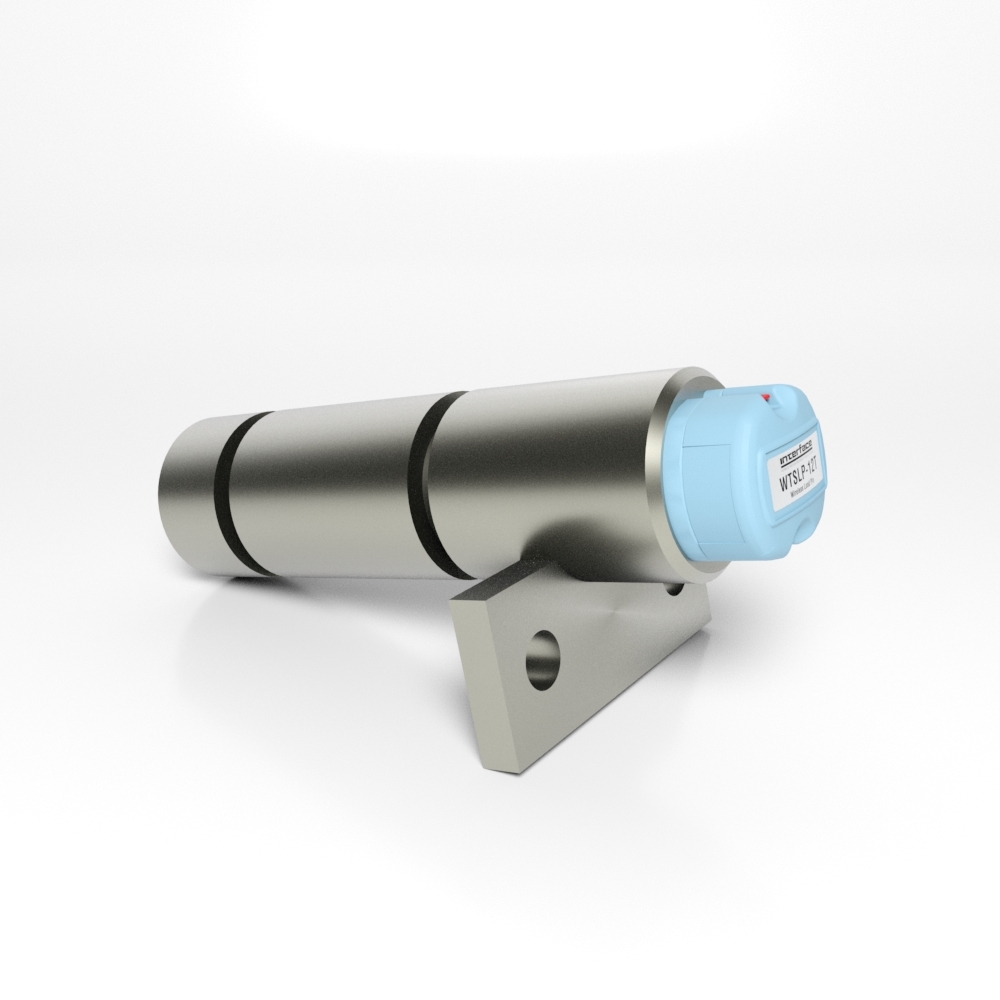

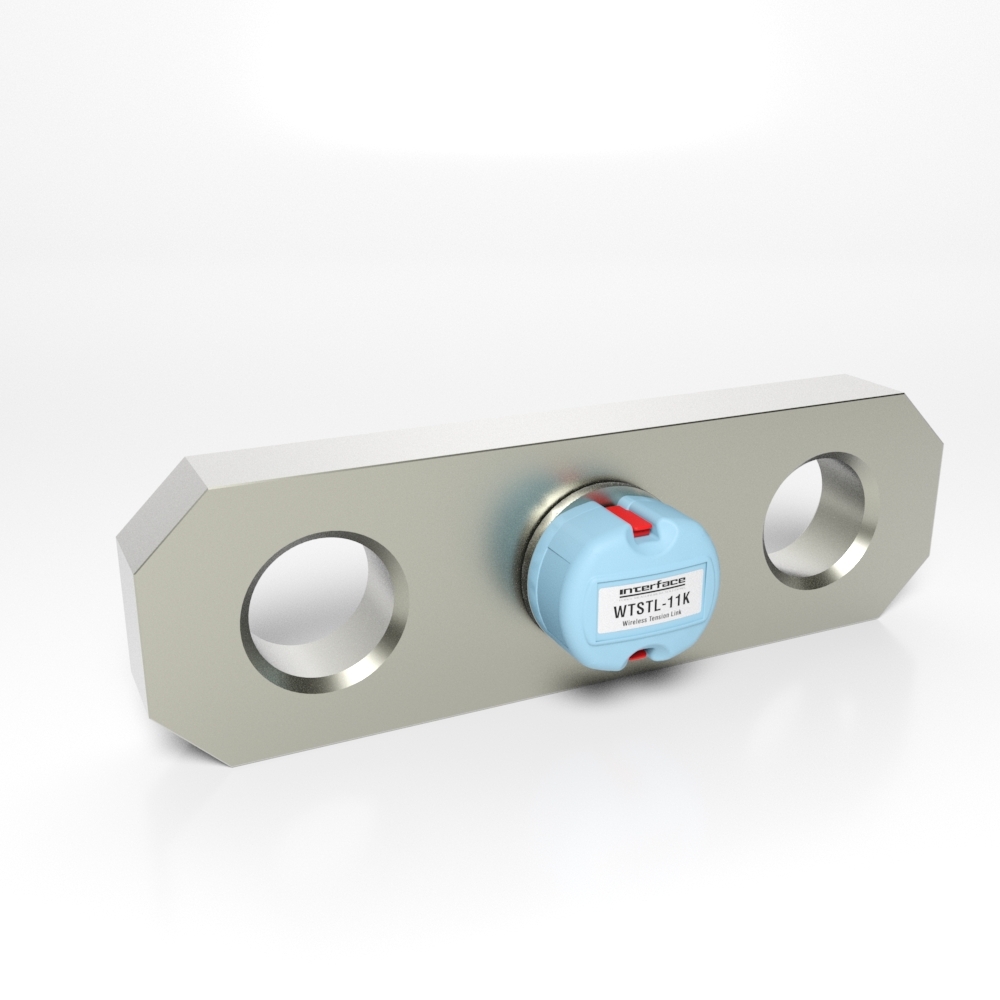

Interface Lifting Solution Products:

Our load pins, load shackles, and tension links provide precise load measurement capabilities, allowing operators to accurately determine the weight of the load being lifted. This information is crucial for ensuring that the lifting equipment remains within safe working limits and prevents overloading situations that could lead to accidents or equipment failure. Interface sensors provide vital force data to identify patterns, detect anomalies, and predict potential issues with lifting equipment and other lifting applications.

The Transformation in Lifting Success

Interface’s force sensor technologies are a necessity in innovative lifting solutions, offering a wide array of benefits and applications. Interface’s load cells, load pins, load shackles and tension links that are strategically embedded in lifting devices, such as cranes, hoists, and robotic arms, measure the forces experienced during the lifting process with high accuracy. By employing our force sensors, operators can obtain real-time feedback on the weight, tension, and pressure exerted on the lifting equipment, allowing for better load management and preventing overloading or potentially hazardous situations.

Our sensor technologies have significantly transformed the way heavy loads are managed on the line, in the warehouse, on the dock, for transportation and in industry specific applications. Multiple lifting activities, from hospital lifts to robotic arms used in packaging, all can achieve enhanced safety, increased efficiency, and improved maintenance practices. The implementation of these technologies marks a transformative step forward in the quest for more precise and controlled lifting operations, ensuring a safer and more productive future across various industries. Check out our new Lifting Solutions Brochure for more information.

Lifting Applications:

- Bridge Construction

- Crane hoisting

- Loading and unloading ships, trucks, or airplanes

- Pallet stacking

- Mining and extraction

- Offshore equipment transportation

- Turbine Installation

- Construction

- Railway lifting and positioning

- Cargo handling

- Patient Hoisting

LiftingSolutions_InfographicPoster