Interface is a Resource to the Forestry Industry

In the forestry industry, sensor technologies play a role in optimizing operations, ensuring safety, and enhancing efficiency in natural resource management.

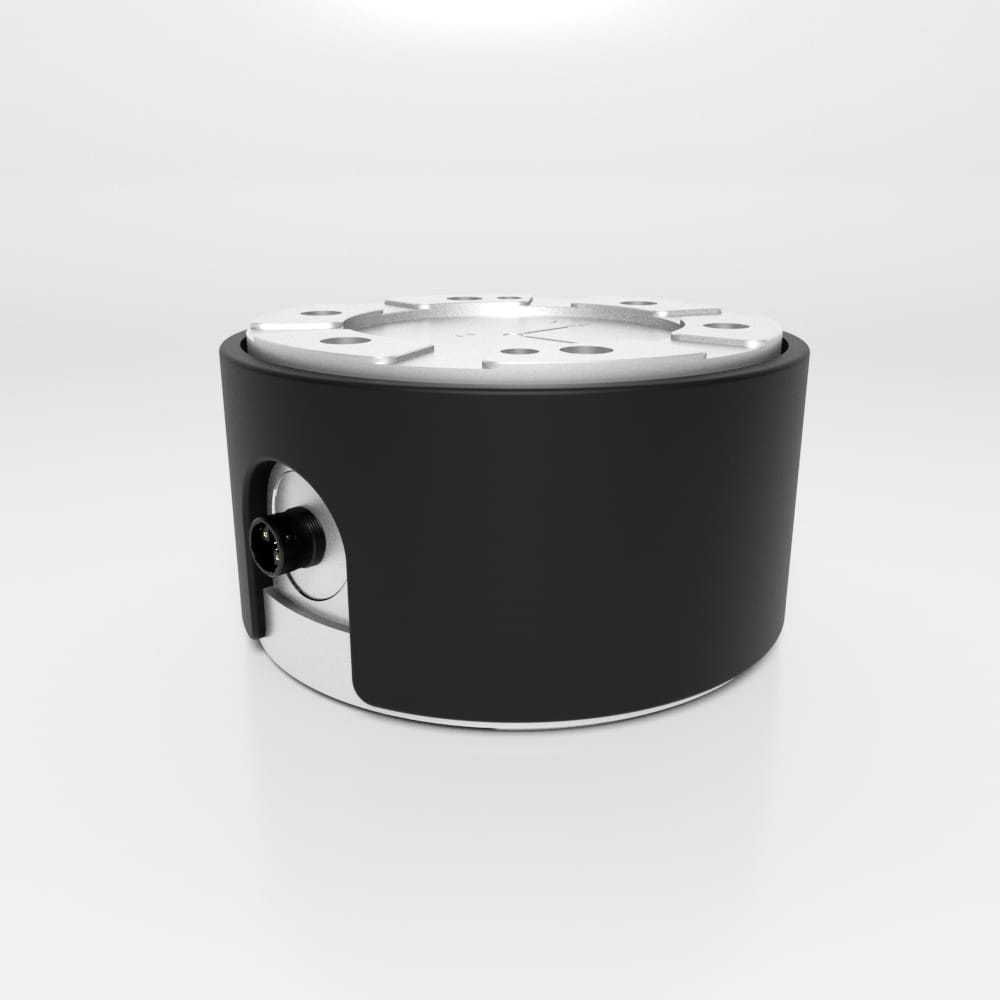

Interface load cells and torque transducers are essential components utilized and implemented across various forestry applications, contributing to sustainable forestry practices. Interface products are ideal for forest management, harvesting, and processing use cases, whether designing heavy machinery using load cells to prevent overloading or protecting operators with sensor-based alarm systems and monitoring tools.

Specifically, Interface devices are used in tree harvesting equipment to measure the force required to cut down trees accurately, ensuring minimal waste and maximizing resource utilization.

Heavy machinery, such as log skidders and loaders, are equipped with force sensors to measure the weight of logs and timber transported precisely. This data aids in preventing overloading, which can damage the equipment and negatively impact the environment.

Interface sensors, including our load pins and load shackles, are used in crane and winch systems to measure weight and load in lifting and lowering logs with the appropriate force.

Monitoring systems are necessary in forestry to monitor the health and stability of trees. By implementing Interface sensors to measure the force exerted on tree trunks due to wind or other environmental factors, forest managers can assess the risk of tree fall and make informed decisions about tree removal to prevent accidents and property damage.

Forestry Applications Using Interface Measurement Solutions:

Forest Management: This involves planning and implementing strategies to maintain and enhance the health and productivity of forests. It includes reforestation, forest inventory, pest control, and wildfire management.

Timber Harvesting: Timber harvesting is cutting and removing trees from forests for various purposes, including producing lumber, pulpwood, and other wood products. Sustainable harvesting practices are essential to ensure the long-term health of forests.

Wood Processing: Once harvested, trees are processed into wood products such as lumber, plywood, particleboard, and wood pulp. These products are used in construction, furniture manufacturing, and paper production.

Non-Timber Forest Products (NTFPs): Besides wood, forests provide a wide range of non-timber forest products, including fruits, nuts, mushrooms, medicinal plants, and wildlife. These products are often harvested sustainably for food, medicine, and other purposes.

Bioenergy: Forest biomass, such as wood chips and sawdust, can be a renewable energy source for biofuels and biomass power generation.

From measuring the weight of logs to ensuring the proper tension in cables and monitoring tree stability, these sensors help optimize forestry practices while minimizing environmental impact and enhancing worker safety. Integrating Interface’s measurement solutions plays a significant role in sustainable forestry management as technology advances.

Forestry_InfographicPoster