Faster, lighter, safer, more responsive automotive vehicle load cell sensors are built at Interface. Nearly every segment of the automotive industry deals with conflicting priorities as they compete to develop new vehicles for their customers. From the focus on extreme performance of racing vehicles to the safety focus of consumer automobiles, Interface can provide force and torque measurement solutions to help you achieve your automotive goals.

We currently supply force and torque sensors directly to automotive OEMs as well as to Tier 1 component vendors and Tier 2 & Tier 3 machine designers, who use Interface force sensors to improve their products and processes.

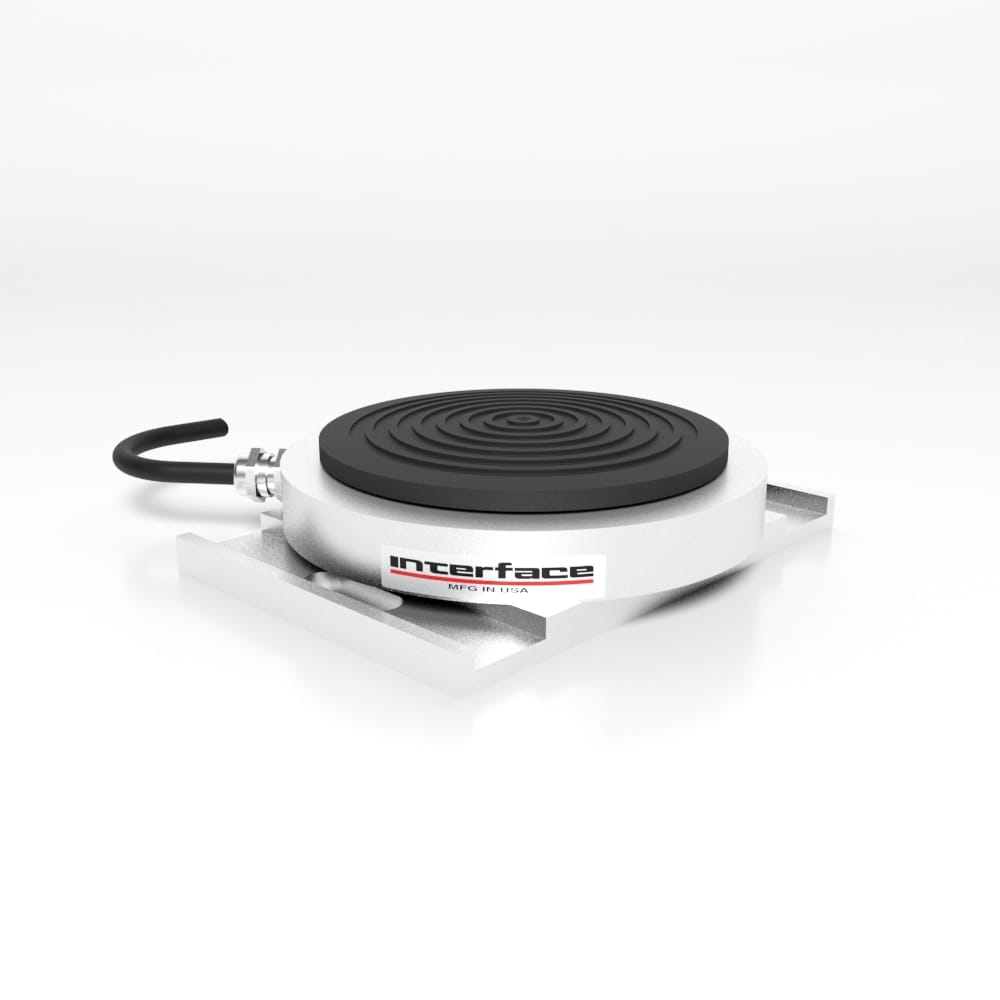

Interface has been supplying high quality, precision load cells to the automotive industry since 1968, including custom one-off sensors and special application-specific designs. Standard off-the-shelf models such as our 2400 series , our 3200 series Stainless Steel LowProfile™ Load Cells or our WMC Miniature Load Cell family are popular with machine builders and used anywhere a rugged stainless steel load cell is required. Research and development facilities with precision applications favor our 1200 Series LowProfile™ Load Cells with their special moment compensated design. These are used in auto manufacturer assembly lines in a variety of production monitoring and verification applications.Our exceedingly accurate LowProfile™ Load Cells have been used in NASCAR and IndyCar garages for testing individual springs and entire vehicle suspensions.

A moment compensated Interface load cell has as much as 1,000 times less error from side load or moment as our competitor’s products. And many of our sensors feature 10x mechanical overload protection, which helps protect against unintended loads. Our Model BPL Load Cell is a very LowProfile™ load cell for measuring force on gas, brake or clutch pedal.

With a wide range of automotive vehicle load cell sensors, force and torque measurement capabilities and features such as moment compensation, temperature compensation, and mechanical overload protection, Interface can help you design a solution perfect for your automotive application.

Automotive + Vehicle Applications:

Smart Transportation

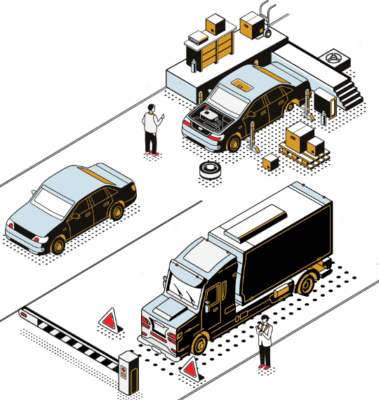

Interface is supporting one of the many revolutions in the automotive and vehicle industry. One such area of rapid transformation is smart transportation, which is a rapidly growing field that is using sensors, data, and analytics to improve the efficiency, safety, and sustainability of transportation systems.

In the automotive industry, sensors are being used to improve a wide range of features, including like crash avoidance, lane departure warnings, adaptive cruise control, EV battery management and autonomous driving. Essentially sensor technologies are making our transportation systems safer and smarter.

In addition to these safety features, sensors are also being used to improve the efficiency and sustainability of vehicles. Sensors can also be used to collect data on traffic patterns and optimize routes, which can help to reduce congestion and

Some examples of smart transportation technologies include:

- Intelligent traffic lights: These lights use sensors to detect traffic flow and adjust the timing of the lights to improve traffic flow.

- Vehicle-to-vehicle communication: This technology allows vehicles to communicate with each other to share information about their speed, location, and intentions. This can help to prevent collisions and improve traffic flow.

- Real-time traffic information: This information can be displayed on signs, apps, or websites to help drivers make informed decisions about their routes.

- Parking guidance systems: These systems use sensors to track the availability of parking spaces and provide real-time information to drivers.

- Autonomous vehicles: These vehicles use sensors and software to drive themselves, without the need for a human driver.

How are Interface products used in smart transportation applications?

- Interface load cells are used to measure the weight of cargo or passengers in a vehicle. This information can be used to optimize the distribution of weight for better handling and fuel efficiency.

- Interface torque transducers measure the amount of torque being applied to the wheels of large transportation vehicles that travels by rail, cable or on the road. This information can be used to improve the performance of the engine and transmission.

- Interface pillow block load cells are used to provide instant feedback for rail transportation, enabling these fast moving vehicles to operate safely across the hills, plains, mountains and desert terrains.

- Interface instrumentation solutions are used to gather the measurement of different aspects of smart vehicles such as speed, temperature, and fuel or battery consumption. This information can be used to provide system management operations feedback in real-time and help to troubleshoot problems.

As this technology continues to develop, we can expect to see even more innovative and efficient ways to get around.

SmartTransportation_Infographic