Whether you are testing tractor engines or weighing feed in silos, the solutions that Interface offer are diverse in capabilities, capacities and use cases. From poultry weighing systems to drones used in crop inspections, our team of experts are able to ensure you get the right solution based on your exact requirements for equipment for your applications.

complete solutions provider

We have a variety of force measurement products that are designed for modern agricultural testing projects and as components for OEMs. Our Interface expert application engineers can help you with standard products as well as design customized solutions for all types of applications using our products that are used for harsh environments, material handling, complex agricultural machines, and extreme weather conditions, engine testing, all ensuring maximum safety and efficiency.

precise data results

Interface load cells and torque sensors are used to give precise data results that is reliable and quintessential for various applications in the agricultural field. For heavy load weighing applications, the A4200 Zinc Plated or A4600 Stainless Steel Weigh-check Load Cells paired with the 1280 Programmable Controller can give accurate measurements.

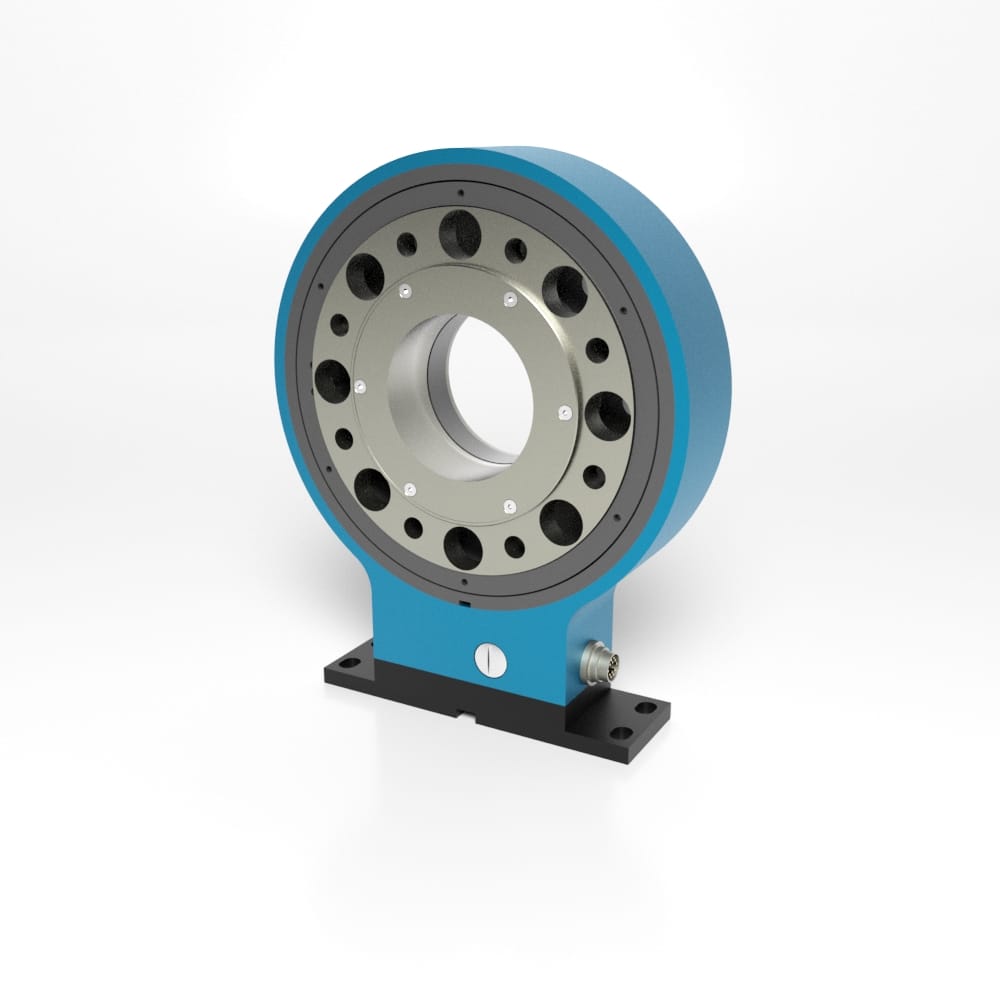

torque applications

For torque applications in tractors and other vehicles, we have different USB options for torque transducers such as the T12, T15, and T25 Rotary Torque Transducers. These options allow for easy integration with our numerous instrumentation solutions, including both digital and analog.

Wireless Products

Our wireless products have been used in equine reins testing. Our engineers designed a way to measure the bit of the reigns strong poll pressure, to study the cheekpiece tension of the reigns for the horse. We were able to produce a Wireless solution that included two SMA Miniature S-Type Load Cells, that was paired with multiple products from our WTS line. These products were the WTS-AM-1E Wireless Strain Bridge Transmitter Module, WTS-BS-1-HA Wireless Handheld Display for Multiple Transmitters, and the WTS-BS-6 Wireless Telemetry Dongle Base Station. The customer can see real-time results on multiple interfaces, such as their computer or the handheld device. A Bluetooth solution was also available for customers to this application. With the same load cells being used, it was paired with our BTS-AM-1 Module Bluetooth Telemetry System. All our WTS and BTS products come with the necessary soft-ware.

ideal for agricultural applications

Our Interface Load Cells, Torque Transducers, and Data Acquisition Systems are ideal for different kinds of agricultural applications. These products can be paired together to measure to ensure efficiency, sustainability, and proper production planning. Interface, Inc’s products can regulate through harsh weather conditions such has humidity and unbearable temperatures- while still maintaining a high testing and measurement performance.

Our custom solutions team will work alongside you to create the most effective and efficient solution based on your needs.

SmartFarming_InfographicPoster

Silo Grain Dispensing

Silo Grain Dispensing