Material Testing

Material testing subjects matters to various mechanical, physical, chemical, and thermal tests to assess their property characteristics and behavior under specific conditions. This includes various forms of force to determine values of fatigue, strength, and failure.

The primary goals of material testing are to determine the material’s suitability for a particular application, ensure quality control, and understand its performance characteristics during various use cases. It is also critical testing for adherence to compliance and regulatory standards.

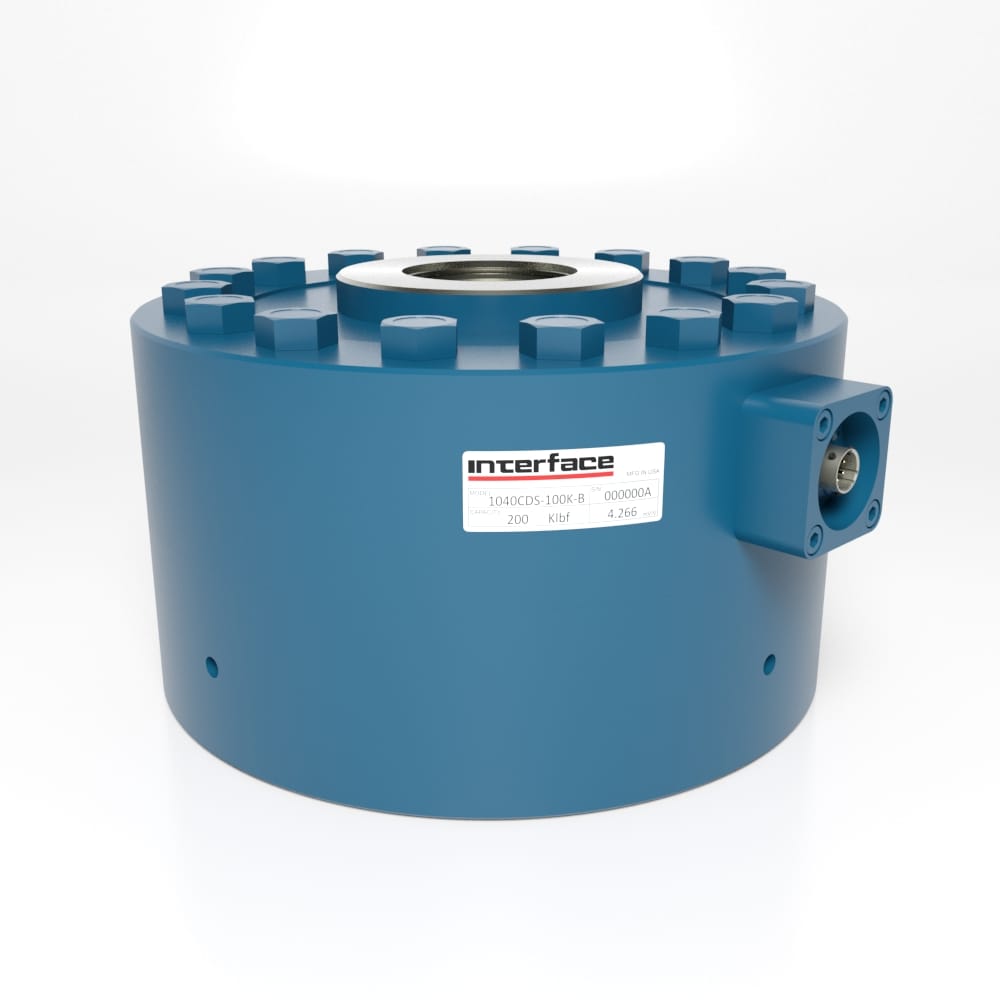

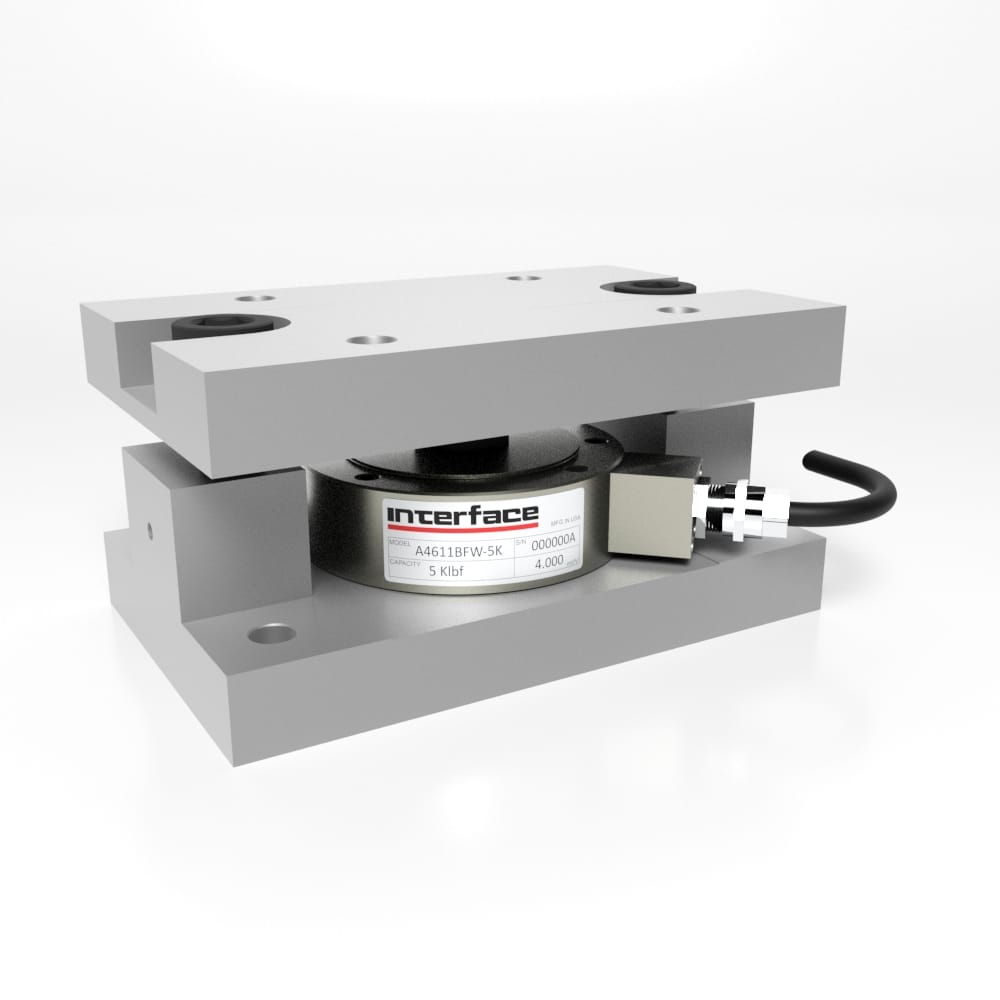

Force measurement plays a huge part during material testing of materials used for various parts, products, structures, and consumer goods. Interface products are commonly found in test machines and equipment used for material testing. Material testing engineers utilize our force sensor technologies, including LowProfile and miniature load cells, DAQ systems, and instrumentation to measure and record the durability, fatigue, safety, and quality of the materials.

Interface’s force sensors are most often used in the material testing category of mechanical testing, including:

- Hardness Testing

- Tensile Testing

- Impact Testing

- Bending Testing

- Fracture Toughness Testing

- Compression testing

- Creep Testing

- Fatigue Testing

- Nondestructive Testing

These types of material tests are used across industries, including medical, infrastructure, aerospace, automotive, industrial automation, manufacturing, consumer goods and in the machines used to assemble products.

Material testing starts early in the research and development phases of product development and continues through packaging. Load cells are used for testing a wide variety of materials across different industries. Materials commonly tested used force measurement solutions:

Metals: Steel, aluminum, and other metallic materials are frequently tested using load cells to determine their tensile and compression strength, yield, fatigue, and other mechanical properties.

Plastics: Load cells are used to test the mechanical properties of polymers and plastics for all types of use cases including tensile strength, bending range and elasticity. As new products are used for 3D printing, this is growing in test use cases.

Construction Materials: Interface precision sensors are used in the material testing of concrete, cement, and construction materials to evaluate their compressive strength, shear strength, and load-bearing capacity.

Textiles and Fabrics: Manufacturers utilize sensors to understand the tensile strength, resistance, and elasticity of textiles.

Biomaterials: Bio researchers use data from load cells to study the mechanical properties of these materials utilized in medical devices, implants, and other health related products.

The versatility of Interface load cells and the accuracy for measurement are why material engineers choose our products for material tests.

MaterialTesting_InfographicPoster

Water Bottle Dispensing and Weighing

Water Bottle Dispensing and Weighing