advancements in robotics

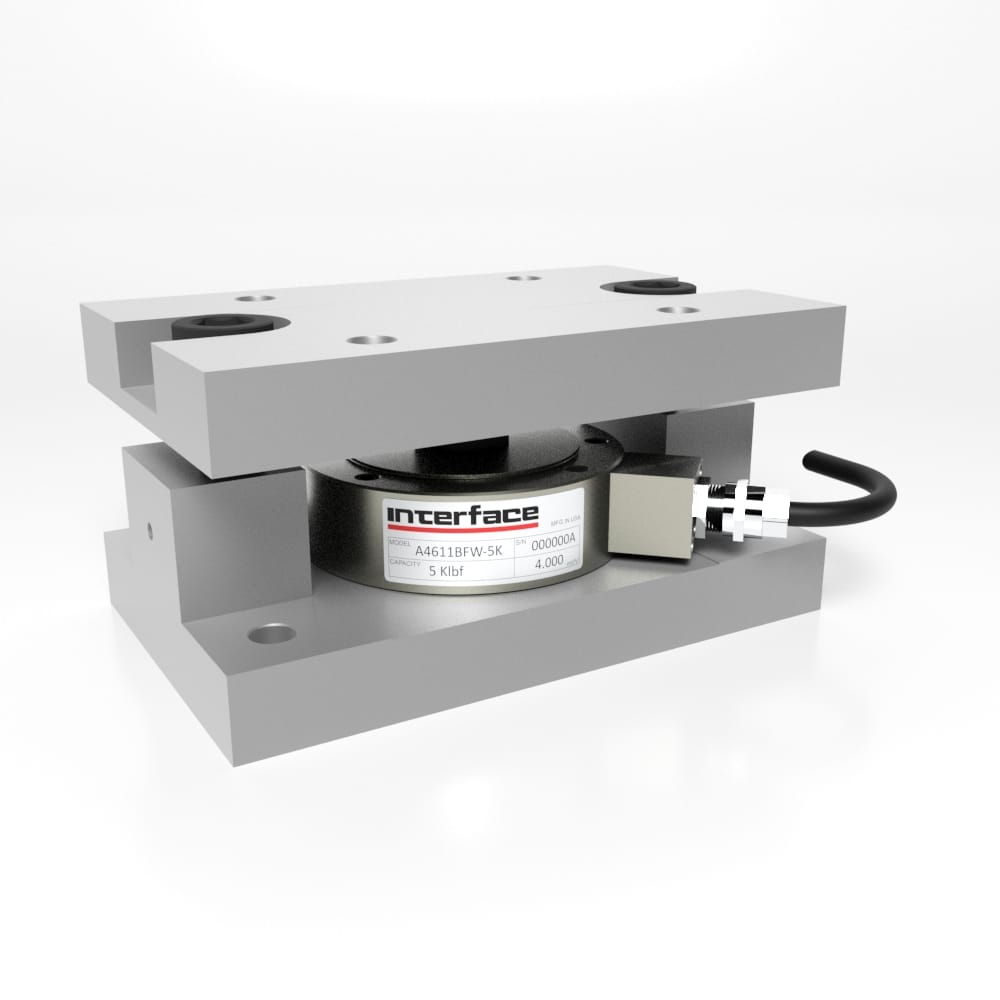

The field of robotics has witnessed remarkable advancements, revolutionizing various industries and transforming how we live and work. Robots and cobots are usually equipped with sensors, actuators, and sophisticated algorithms to perceive and interact with their environment. Interface sensors are utilized in designing, testing, and using robotics. Engineers turn to Interface for load cells, torque transducers, multi-axis sensors and instrumentation for testing and to embed into robots for real-time feedback.

Robotics and collaborative robots, often called cobots, have gained significant attention due to their ability to work alongside humans, enhancing productivity, safety, and efficiency in numerous applications. Cobots collaborate with humans in shared workspaces and are designed to work alongside human operators, supporting them in various tasks. These robots are designed to be safe, easy to program, and capable of adapting to dynamic environments.

Whether it’s crafting special transducers to meet your unique needs or creating fully customized sensors, instrumentation, and software systems, we collaborate closely as part of your team to ensure precision and satisfaction.

Interface Products Used in Robot and Cobot Applications

- Load Cells

- Multi-Axis Sensors

- Digital Instrumentation

- Torque Transducers

- Wireless Telemetry Solutions

- Weighcheck Systems

- S-Type Load Cells

- Load Pins

- Load Buttons

- Interface Mini™ Load Cells

- Signal Conditioners

- Instrumentation

Robots and cobots are highly versatile and adaptable to changing production demands, offering enhanced efficiency and agility in manufacturing processes. As the field of robotics progresses, cobots are set to play a significant role in shaping the future of work, creating a harmonious synergy between humans and machines.

Robotics_InfographicPoster

Using Interface load cells and torque transducers in robotics offers several benefits. First, they can help to improve safety by detecting excessive forces or overloads. Second, they can help to optimize performance by providing feedback about the forces being applied by the robot. Third, they can enable more sophisticated control of robotic systems by providing real-time data about the generated forces and torques. Our miniature load cells are commonly used by robotic OEMs to provide control and feedback. Download our brochure to learn more.

Robotics Tri-Fold