Hydraulic fracturing is known in the energy sector as fracking. It is a process used for extracting oil and natural gas from underground. With natural gas consumption in the United States reaching a new record in 2024, methods to meet the demands require sensor-based solutions safely and efficiently.

Hydraulic fracturing is a means to expedite natural gas production. This method involves injecting a high-pressure fluid, often a mix of water, chemicals, and proppants, into the rock to create fractures. Proppant is a granular material like sand or ceramic beads injected into oil or gas wells at high pressure to hold open fractures in the rock formation, allowing for the extraction of energy sources.

As a supplier of choice in the energy sector, our load cells are integrated into the pumping systems, tension monitoring equipment, downhole simulators, wireline equipment, and wells.

Concerning hydraulic fracturing, Interface force measurement products help monitor the precise amount of proppant being pumped into the well. Interface sensor technologies are commonly used in hydraulic fracturing and proppant applications to measure the force or pressure exerted during fracking accurately.

We have developed standard and engineered-to-order solutions for these environments using our experience, technologies, and proprietary strain-gaged solutions specifically for downhole applications.

Examples of Interface Products for Hydraulic Fracturing

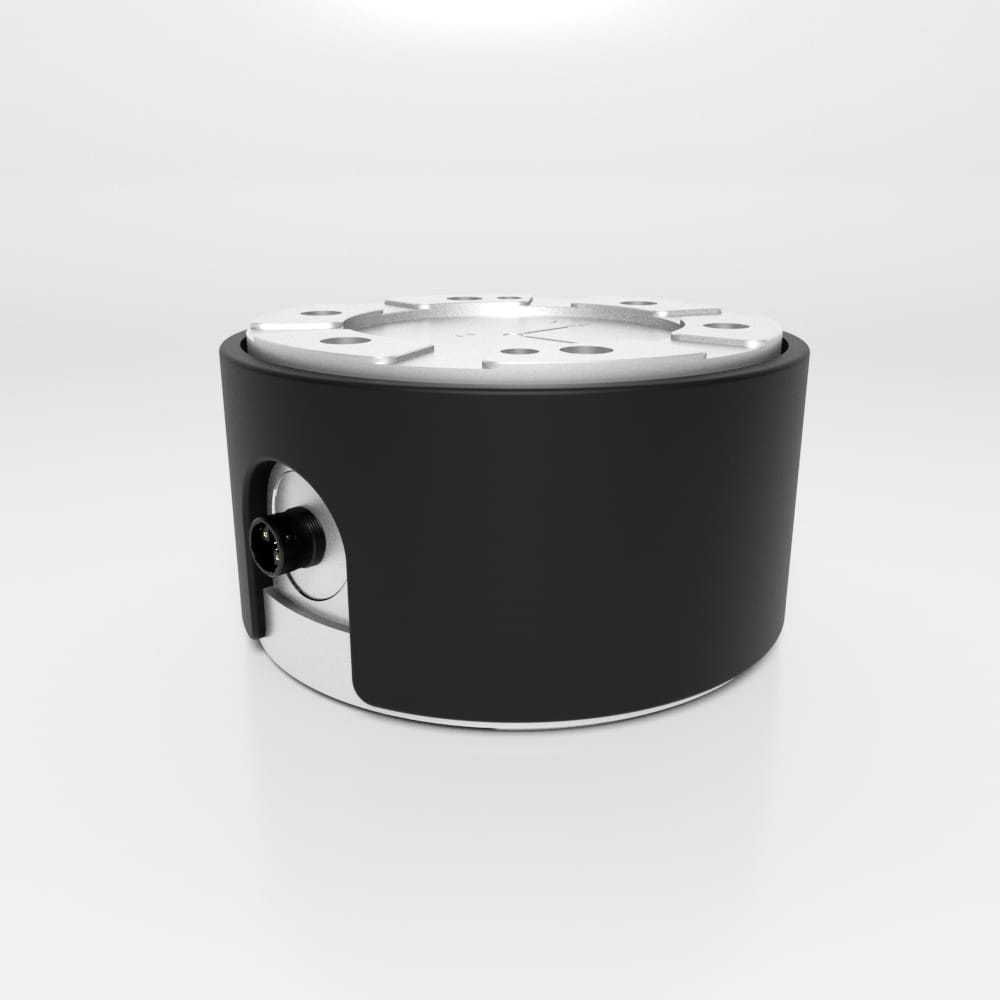

- Interface Pressure Compensated Downhole Cell Model (IPCD) is pressure compensated up to 20,000 PSI, temperature compensated up to 350°F. It is superior to hydraulically compensated wet load cells, which have a short life expectancy and high operating costs

- Axial Force Pressure (AFP) tension and compression load cell and a pressure transducer with 2 discrete Wheatstone bridges for output utilize a matrix conversion process to determine force and pressure.

- Custom Load Pins in various sizes and capacities to work within fracturing equipment.

Load cells have precise measurement capabilities necessary for maintaining optimal fracking conditions. Overloading or underloading the well with proppant can result in suboptimal fracturing, compromising well productivity, or even causing structural damage to the wellbore.

Hydraulic Fracturing Applications Using Interface Sensor Technologies

- Downhole Tension Monitoring

- Tool Strings

- Wireline Equipment Monitoring

- Proppant Injection Monitoring

- Fracturing Pressure Monitoring

- Proppant Transport

- Proppant Storage Silos

- Proppant Testing and Quality Control

- Wellbore Stability Monitoring

- Pump Tools

Interface load cells are used in equipment for measuring factors that impact safety and environmental sustainability in hydraulic fracturing operations. For example, by accurately measuring forces exerted during proppant handling, load cells may lessen the risk of equipment failure or unintended environmental impacts.

Interface’s load cells and instrumentation provide precision, reliability, and real-time monitoring capabilities. The data we provide using our force sensors also helps evaluate the effectiveness of the hydraulic fracturing operation, thus optimizing future procedures for maximum output.