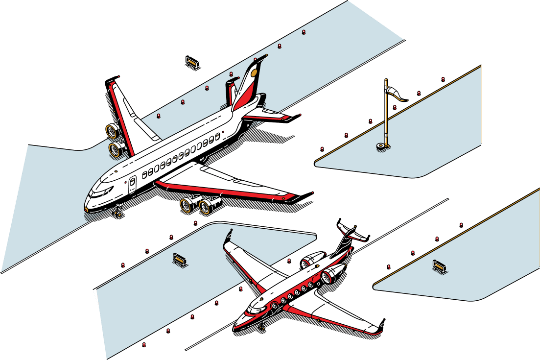

Aerospace

Aircraft, spacecraft, military and defense companies such as Boeing, Airbus, Lockheed, Northrop, Bombardier, Embraer, Gulfstream, NASA and Cessna have depended on Interface load cells for thrust, wing, static and fatigue testing.

Planetary Sample Collecting Propeller Testing Reduced Gravity Simulation Rescue Helicopter Hoist Test Rocket Center of Gravity Rocket Structure Testing

Planetary Sample Collecting Propeller Testing Reduced Gravity Simulation Rescue Helicopter Hoist Test Rocket Center of Gravity Rocket Structure Testing Rover Landing Gear

Rover Landing Gear Rover Wheel Torque Monitoring Satellite Deployment Space Dock Capture Ring Force Testing Spacecraft Repair Robot Spacewalk Simulator Vacuum Testing for Aviation Performance Wind Tunnel

Rover Wheel Torque Monitoring Satellite Deployment Space Dock Capture Ring Force Testing Spacecraft Repair Robot Spacewalk Simulator Vacuum Testing for Aviation Performance Wind TunnelThe aerospace industry encompasses many sectors, including jetliners to rockets. The leaders in these sectors utilize our standard load cells and sensor technologies, as well as engineered-to-order and completely custom solutions to advance their inventions and test their craft. We are known for our ability to meet the exact specifications in capacities, capabilities and use case requirements for testing and measuring performance in the design and manufacturing of all types of flight vehicles. Since 1968, we have partnered through the advancements and innovations to go above and beyond.

Interface is renowned for its exceptional sensors that deliver high performance in various test and measurement applications. With a legacy spanning over five decades, aerospace pioneers and industrial giants have placed their trust in Interface to provide precise products and reliable services. Our unwavering commitment to quality, dependability, and accuracy has become the benchmark for everything we engineer and manufacture.

Our solutions are specifically designed to meet the demanding needs of the aerospace industry, where they must endure extreme conditions. Whether it involves testing wings for commercial airplanes or measuring the force exerted during the launch of an intergalactic vessel, Interface’s standard load cells and sensor technologies are utilized. Additionally, we offer engineered-to-order and fully customized solutions to cater to specific requirements. Our expertise lies in meeting exact specifications in terms of capacities, capabilities, and use cases, enabling accurate testing and measurement of performance across the design and manufacturing processes of all types of flight vehicles.

Since our establishment in 1968, we have forged strong partnerships that have propelled advancements and innovations in the aerospace industry. Our commitment to going above and beyond has been instrumental in driving progress and exceeding expectations in this dynamic field.