Detailing Pillow Block Load Bearing Load Cells

A pillow block bearing is usually used to create a rolling system. This bearing type is often used for industrial rolls for textiles, paper, and materials. It is also used on conveyor belts in manufacturing facilities. Other common use cases in various industries include transportation, medical device design, and aerospace.

A pillow block bearing is usually used to create a rolling system. This bearing type is often used for industrial rolls for textiles, paper, and materials. It is also used on conveyor belts in manufacturing facilities. Other common use cases in various industries include transportation, medical device design, and aerospace.

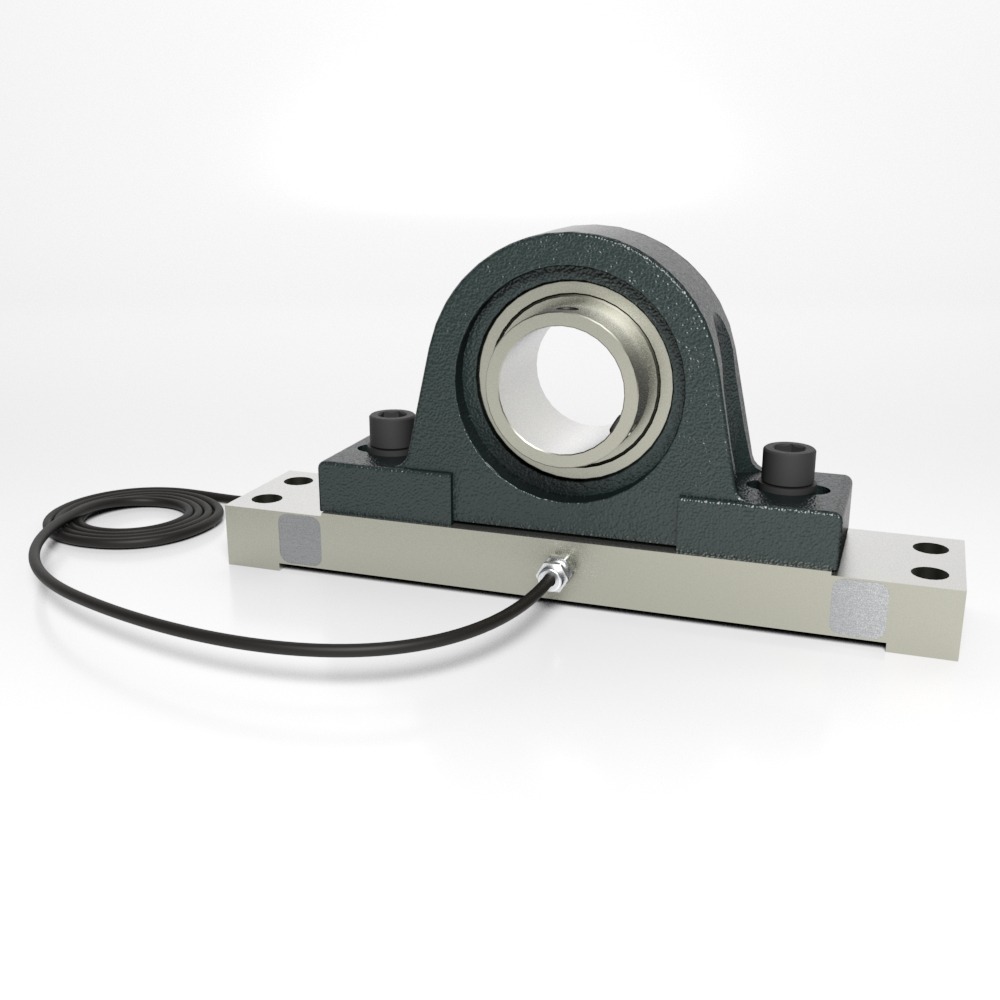

Interface offers specialized load cells that measure and monitor weight and other forces on pillow block bearings, aptly known as Interface Pillow Block Load Bearing Load Cells. The force measurement is performed for this load cell between two supports.

Pillow block bearing load cells are important in all industries where accurate load measurement is required during production and use of small and large rollers. Some examples include:

- Steel industry: Pillow block load cells can be used in roller mills to measure the force required to crush or shape steel.

- Textile industry: Pillow block load cells can be used in textile machines such as looms and knitting machines to measure the tension on the yarn.

- Packaging industry: Pillow block load cells can be used in packaging machines to measure the force required to cut or seal packaging materials.

Pillow block load cells are valuable in building and enhancing infrastructure. Our PBLC1 is a great solution for monitoring trains on a track in motion. When our PBLC1 is installed on a track, and the train runs across it, the sensor can provide a signal to a station elsewhere in the world. If any force indicators suggest that there could be a problem with the weight the train is holding or the train itself, the sensor can also trigger an automatic shutdown of the train. These sensors could prevent major damage from train derailments and other train-related incidents by detecting errors before they inflict damage.

Pillow block load cells are valuable in building and enhancing infrastructure. Our PBLC1 is a great solution for monitoring trains on a track in motion. When our PBLC1 is installed on a track, and the train runs across it, the sensor can provide a signal to a station elsewhere in the world. If any force indicators suggest that there could be a problem with the weight the train is holding or the train itself, the sensor can also trigger an automatic shutdown of the train. These sensors could prevent major damage from train derailments and other train-related incidents by detecting errors before they inflict damage.

These weights are important to measure or monitor as they can tell you if you run out of material on a roll or if a production line conveyor belt is holding too much weight. An example of the feed roller system using our wireless options is below.

Manufacturing Feed Roller System

In addition to this use case, here are a few other ways Pillow Block Load Cells are used to measure weight and force:

- Material handling: Pillow block load cells are commonly used in conveyor systems to measure the weight of transported materials.

- Automotive industry: Pillow block load cells are used in assembly line applications to measure the weight of assembled parts and components.

- Heavy machinery: Pillow block load cells are used in cranes, bulldozers, and other heavy machinery to measure loads and monitor the equipment’s performance.

- Manufacturing: Pillow block load cells are used in material testing machines to measure the force required to break or deform materials.

- Aerospace: Pillow block load cells are used in aerospace applications to measure the weight and balance of aircraft and spacecraft.

- Medical industry: Pillow block load cells are used in medical equipment such as patient lifts and hospital beds to measure patients’ weight.

- Food industry: Pillow block load cells are used in food processing and packaging equipment to measure the weight of ingredients and finished products.

Pillow Block Bearing Load Cells Product Overview

This type of force sensor is suitable for measuring forces under pillow block bearings for diameter Ø 20mm (Ø 0.79 in) and for measuring axle weight in test stands for trains and vehicles. Our system is compatible with INA Pillow Block Bearings and is installed underneath the bearing to measure force. There are three model versions, with the options for additional multi-axis measurements for engineers to order products.

PBLC1 Pillow Block Load Bearing Load Cell

PBLC2 Pillow Block Load Bearing Load Cell

PBLC3 Pillow Block Load Bearing Load Cell

Features and benefits of our Pillow Block Load Cell include:

- Capacities from 5 to 30 kN (1.1K to 6.7K lbf)

- Compatible with INA pillow block bearings

- IP65 moisture protection

- Rugged electro-galvanized surface

In addition, our Pillow Block Load Cell is also available in multi-axis versions, allowing more force data from your test application. This helps measure forces such as the center of gravity, tension across a load-bearing beam, and more. These multi-axis versions come in two and three-axis models. If you want accurate measurements for your pillow block-bearing use cases, contact our specialized application engineers.

ADDITIONAL RESOURCES

Interface Manufacturing and Production Solutions

Quality Engineers Require Accurate Force Measurement Solutions

Interface New Product Releases Winter 2023

Infrastructure Industry Relies on Interface Force Measurement

Interface Solutions for Production Line Engineers