Material Testing

Material testing subjects matters to various mechanical, physical, chemical, and thermal tests to assess their property characteristics and behavior under specific conditions. This includes various forms of force to determine values of fatigue, strength, and failure.

The primary goals of material testing are to determine the material’s suitability for a particular application, ensure quality control, and understand its performance characteristics during various use cases. It is also critical testing for adherence to compliance and regulatory standards.

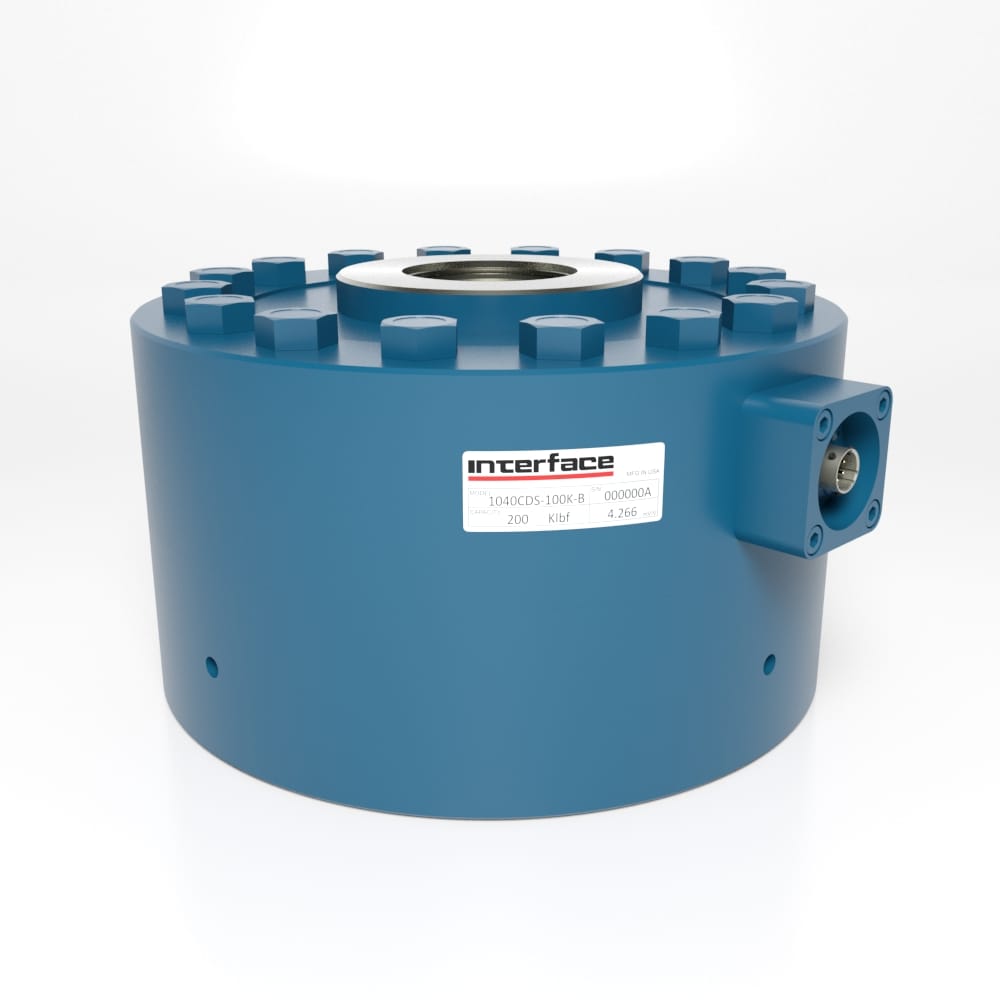

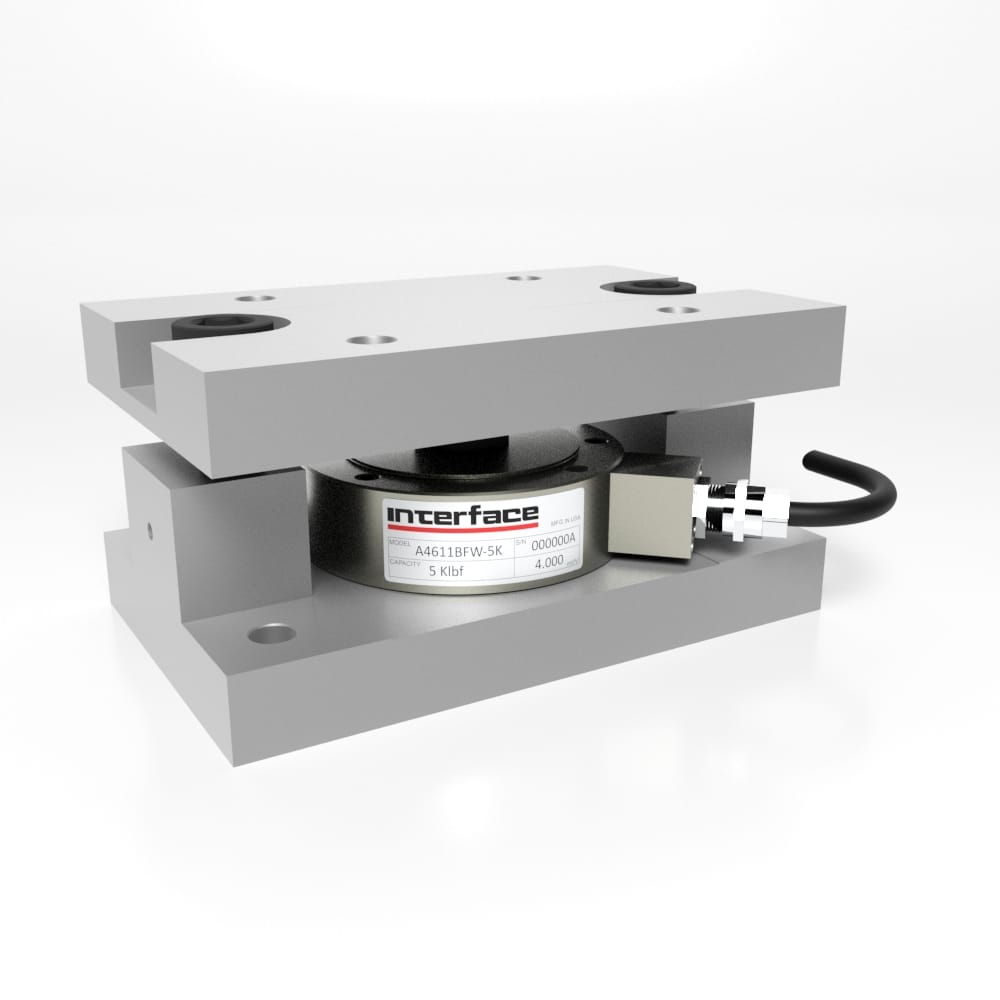

Force measurement plays a huge part during material testing of materials used for various parts, products, structures, and consumer goods. Interface products are commonly found in test machines and equipment used for material testing. Material testing engineers utilize our force sensor technologies, including LowProfile and miniature load cells, DAQ systems, and instrumentation to measure and record the durability, fatigue, safety, and quality of the materials.

Interface’s force sensors are most often used in the material testing category of mechanical testing, including:

- Hardness Testing

- Tensile Testing

- Impact Testing

- Bending Testing

- Fracture Toughness Testing

- Compression testing

- Creep Testing

- Fatigue Testing

- Nondestructive Testing

These types of material tests are used across industries, including medical, infrastructure, aerospace, automotive, industrial automation, manufacturing, consumer goods and in the machines used to assemble products.

Material testing starts early in the research and development phases of product development and continues through packaging. Load cells are used for testing a wide variety of materials across different industries. Materials commonly tested used force measurement solutions:

Metals: Steel, aluminum, and other metallic materials are frequently tested using load cells to determine their tensile and compression strength, yield, fatigue, and other mechanical properties.

Plastics: Load cells are used to test the mechanical properties of polymers and plastics for all types of use cases including tensile strength, bending range and elasticity. As new products are used for 3D printing, this is growing in test use cases.

Construction Materials: Interface precision sensors are used in the material testing of concrete, cement, and construction materials to evaluate their compressive strength, shear strength, and load-bearing capacity.

Textiles and Fabrics: Manufacturers utilize sensors to understand the tensile strength, resistance, and elasticity of textiles.

Biomaterials: Bio researchers use data from load cells to study the mechanical properties of these materials utilized in medical devices, implants, and other health related products.

The versatility of Interface load cells and the accuracy for measurement are why material engineers choose our products for material tests.

MaterialTesting_InfographicPoster

Water Bottle Dispensing and Weighing

Water Bottle Dispensing and Weighing

Data Acquisition Systems 101

/in 101 Series, Blog /by Jamie GlassEngineers and testing professionals use data acquisition systems to enable smart decisions. The data retrieved through DAQ systems empower users to identify points of failure, optimize performance, and create efficiencies in products and processes. When it comes to measuring force, […]

Interface Best Selling Products in 2022

/in Blog /by Jamie GlassInterface sells tens of thousands of force measurement products every year. As a manufacturer of the world’s highest quality load cells, it is no surprise that our top selling products are the precision load cells that we engineer and build […]

Most Popular Interface Content in 2022

/in Blog /by Jamie GlassInterface is committed to providing valuable content and resources related to force measurement and supplemental topics based on how our customers use our products. Every year, we publish content in a variety of formats, including our blogs, newsletters, catalogs and […]

Exploring Interface Capabilities and Differentiators

/in Blog /by Jamie GlassInterface is the largest producer of load cells defined by a particularly important core differentiator. The Interface difference is precision. How do we maintain this standard of excellence? Interface is directed by our foundational 4-pillars for success: quality, service, accuracy, […]

Types of Force Measurement Tests 101

/in 101 Series, Blog /by Jamie GlassThere are distinct types of force tests that engineers, product designers, manufacturers, and test labs perform to accurately measure factors that control quality, safety, and reliability. Testing force helps to qualify how something will react when applying load, either by […]

Interface Solutions for Material Testing Engineers

/in Blog /by Jamie GlassForce measurement inherently is part of all types of engineering throughout the entire development process of products, structures, consumer goods, and the materials used to construct them. In the beginning of the design and development processes, material testing engineers utilize […]

New Interface Case Study Exams Weighing and Scales

/in Blog /by Jamie GlassTest and measurement are used in the development and monitoring of manufactured goods across all industries. With a history of producing force measurement solutions for more than five decades, Interface has supplied a myriad of sensor devices for hundreds of […]

Fitness Equipment Makers Require Extreme Accuracy

/in Blog /by Jamie GlassInterface’s specialty is building solutions for the testing and monitoring of parts and total systems that move and create force. One of the industries where this is critical is the fitness industry. Equipment and fitness machines, whether designed for in-home […]

Interface and Infrastructure Markets Form a Perfect Partnership

/in Blog /by Jamie GlassInfrastructure projects are growing, as investment continues to climb for projects related to rebuilding, renewing and innovating applications in this sector. These global investments come from public and private organizations as demands to address roads, bridges, water supplies, transportation, energy […]

Users of Interface Test and Measurement Products

/in Blog /by Jamie GlassInterface has a long history working with several types of users that rely on our products for test and measurement. From pioneering engineers working in campus labs to ground-breaking scientists and innovators finding solutions to complex problems. We often share […]