Material Testing

Material testing subjects matters to various mechanical, physical, chemical, and thermal tests to assess their property characteristics and behavior under specific conditions. This includes various forms of force to determine values of fatigue, strength, and failure.

The primary goals of material testing are to determine the material’s suitability for a particular application, ensure quality control, and understand its performance characteristics during various use cases. It is also critical testing for adherence to compliance and regulatory standards.

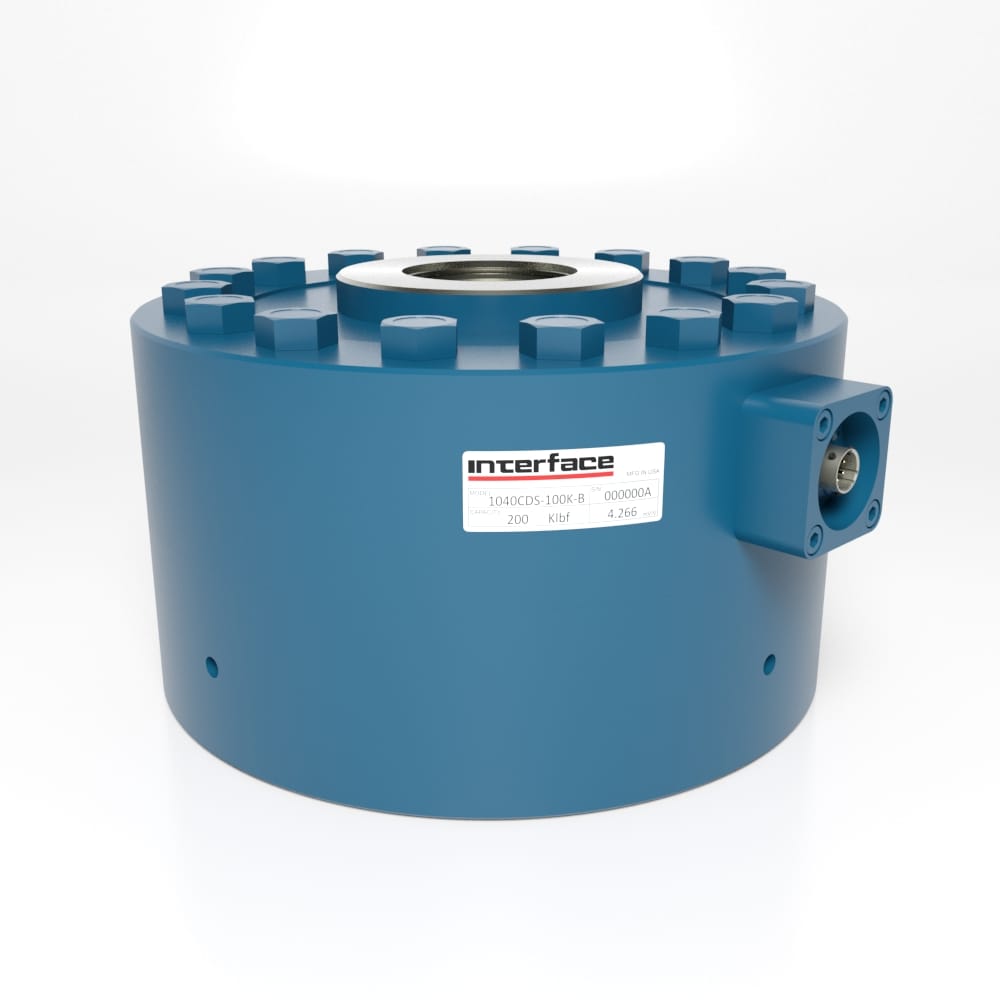

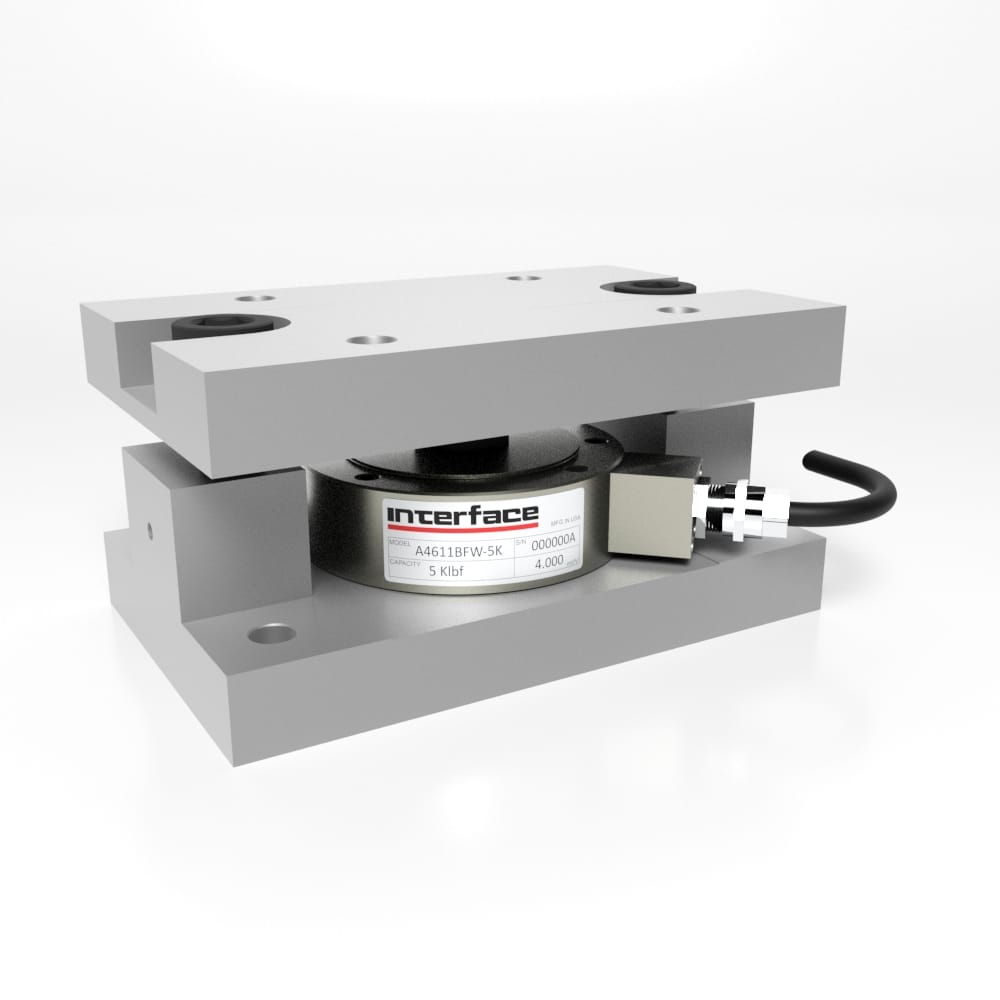

Force measurement plays a huge part during material testing of materials used for various parts, products, structures, and consumer goods. Interface products are commonly found in test machines and equipment used for material testing. Material testing engineers utilize our force sensor technologies, including LowProfile and miniature load cells, DAQ systems, and instrumentation to measure and record the durability, fatigue, safety, and quality of the materials.

Interface’s force sensors are most often used in the material testing category of mechanical testing, including:

- Hardness Testing

- Tensile Testing

- Impact Testing

- Bending Testing

- Fracture Toughness Testing

- Compression testing

- Creep Testing

- Fatigue Testing

- Nondestructive Testing

These types of material tests are used across industries, including medical, infrastructure, aerospace, automotive, industrial automation, manufacturing, consumer goods and in the machines used to assemble products.

Material testing starts early in the research and development phases of product development and continues through packaging. Load cells are used for testing a wide variety of materials across different industries. Materials commonly tested used force measurement solutions:

Metals: Steel, aluminum, and other metallic materials are frequently tested using load cells to determine their tensile and compression strength, yield, fatigue, and other mechanical properties.

Plastics: Load cells are used to test the mechanical properties of polymers and plastics for all types of use cases including tensile strength, bending range and elasticity. As new products are used for 3D printing, this is growing in test use cases.

Construction Materials: Interface precision sensors are used in the material testing of concrete, cement, and construction materials to evaluate their compressive strength, shear strength, and load-bearing capacity.

Textiles and Fabrics: Manufacturers utilize sensors to understand the tensile strength, resistance, and elasticity of textiles.

Biomaterials: Bio researchers use data from load cells to study the mechanical properties of these materials utilized in medical devices, implants, and other health related products.

The versatility of Interface load cells and the accuracy for measurement are why material engineers choose our products for material tests.

MaterialTesting_InfographicPoster

Water Bottle Dispensing and Weighing

Water Bottle Dispensing and Weighing

Force Measurement is Fundamental in Material Testing

/in Blog /by Jamie GlassInterface load cells, multi-axis sensors, and data acquisition systems are used for material testing. Common uses of force measurement in material tests include applications to measure hardness, torsion, strength, compression, bending, shear, impact, creep, fatigue, and nondestructive capabilities. It is common to have our 1200 LowProfile load cells installed into material testing machines at test labs and onsite. We also supply a variety of miniature load cells and load pins for material testing, depending on the type of equipment and environment used for tests.

Engineered Solutions for Lifting Webinar

/in Virtual Event /by Jamie GlassInterface’s technical webinar Engineered Solutions for Lifting details measurement devices used in lifting equipment, machines, and vehicles to improve operations and safety. Interface load cells and instrumentation are used to operate cranes, hoist heavy objects, and measure forces in infrastructure projects. Interface experts answer how load cells are used in safety monitoring for lifting equipment. Learn about Interface sensor products suited for integration into existing equipment and test and measurement projects.

Demystifying Specifications Webinar

/in Virtual Event /by Jamie GlassInterface’s technical force measurement webinar Demystifying Specifications details descriptions, terms, values and parameters found in product datasheets for load cells, torque transducers, instrumentation and specialty products. Learn from our experts what specifications need critical review, recommendations based on product categories, and the insider point of view on what is most important in terms of specifications for different use cases and tests.

Understanding GUM and Measurement Uncertainty

/in Blog /by Jamie GlassGUM, the Guide to the Expression of Uncertainty in Measurement, defines terms and concepts related to uncertainty. GUM describes methods for uncertainty calculation, and offers guidance for reporting and the documentation of uncertainties in measurement results. Interface knows that understanding GUM and the adherence to good test and measurement practices are essential to minimize uncertainties and ensure reliable measurement results for every application. In addition, reducing uncertainty with regular calibration of testing devices and proper maintenance of the equipment go hand-in-hand with GUM.

Unlocking the Power of DAQ Webinar Recap

/in Blog /by Jamie GlassInterface hosted a technical seminar on the topic of data acquisition systems. With the demands for more data and faster processing with requirements to connect multiple devices in testing environments, there is an increasing need for high accuracy DAQ systems. […]

Testing Labs Choose Interface High Accuracy Products

/in Blog /by Jamie GlassTesting labs choose Interface test and measurement solutions. We supply lab engineers with high-accuracy load cells, calibration-grade equipment, load frames and test stands, plus instrumentation used to complete rigid test requirements. Interface is the top provider of test and measurement products used for structural and material testing, static and fatigue testing, torsion effects, tension tests, calibration testing, and environmental testing

Interface and Testing Lab Applications

/in Blog, Test and Measurement /by Jamie GlassThroughout the Test and Measurement industry, there are several different classifications and testing lab types. Each of these different testing labs provide unique equipment for different forms of testing depending on the application, system or component. Interface offers one of the most diverse force, torque, and weight related force sensor product lines in the market. It is why labs prefer Interface. In addition to our expanding line of data acquisition systems, software and accessories, T&M engineers and lab pros find Interface as a one-stop-shop for simple and complex testing projects.

Unlocking the Power of DAQ Webinar

/in Virtual Event /by Jamie GlassInterface webinar Unlocking the Power of DAQ details trends, best practices and considerations for using data acquisiton in force measurement applications. We explore DAQ instrumentation options, trends and set-up options. Learn why data acquisition systems are growing in popularity for all types of use cases. We also detail the new Interface Data AQ Packs and system options for capturing critical data. Watch the online technical seminar for recommendations on equipment, plus we answser the most frequently asked questions about DAQ in test and measurement.

Interface Solutions for Safety and Regulation Testing and Monitoring

/in Blog /by Jamie GlassAmong the many challenges we help to solve, safety and the stringent requirements for helping to make products safer for all types of users is top of the list. Interface’s solutions are known for quality and accuracy, which are at […]

How Do Load Cells Work?

/in Blog /by Jamie GlassWhat is the most frequently searched question searched related to Interface and the products we manufacture? It may seem overly simple to test engineers and frequent buyers of Interface force measurement solutions, but to many it is an important question. […]