Why Choose a Single Point Impact Cell?

A single point impact load cell (SPI) is a sensor that measures the impact force or load accurately applied to the force or weight exerted on a single point. SPI load cells offer precise and reliable measurements of impact forces or loads, making them valuable tools in various industries and applications.

A single point impact load cell (SPI) is a sensor that measures the impact force or load accurately applied to the force or weight exerted on a single point. SPI load cells offer precise and reliable measurements of impact forces or loads, making them valuable tools in various industries and applications.

SPI load cells are used in various industries where precise measurement of impact forces or loads at a single point is required. Here are four common use cases:

- Material Testing: SPI load cells measure the impact resistance and mechanical properties of materials such as metals, plastics, composites, and rubber. These load cells are employed in impact testing machines to accurately measure the force exerted during impact tests, fracture toughness tests, and other mechanical tests on materials. Most product designers heavily rely on material testing for early-stage concepts to final-stage production.

- Packaging and Filling Machinery: SPI load cells are utilized in packaging and filling machinery to ensure accurate container filling. These load cells measure the force exerted by the product as it is dispensed into containers, allowing precise control of filling volumes and ensuring consistency in product packaging. It is a way to eliminate waste.

- Industrial Automation and Robotics: SPI load cells play a vital role in industrial automation and robotics applications, where precise force measurement is necessary for tasks such as material handling, assembly, and quality control. These load cells are integrated into robotic grippers, end-effectors, and assembly fixtures to monitor and control the forces exerted during robotic operations, ensuring accurate and reliable performance.

These are just a few examples of the diverse applications of SPI load cells across industries. Their ability to provide precise measurements of impact forces or loads at a single point makes them invaluable tools in various industrial processes and testing procedures.

Although the SPI resembles what is sometimes referred to as weigh pan cells, the single point impact cell was specifically designed to have greater than normal deflection at full scale to provide for the addition of stops to protect the cell against compression overloads. This was necessary because the usual deflection of 0.001 inch to 0.006 inch of most load cells is too small to adjust an external stop to protect the load cell accurately.

NOTE: A weigh pan cell, also known as a weigh module or load cell assembly, is a type of sensor system used for accurately measuring the weight or mass of objects placed on a platform or pan. It typically consists of one or more load cells mounted within a housing or frame structure. See more about SPIs in our Load Cell Field Guide.

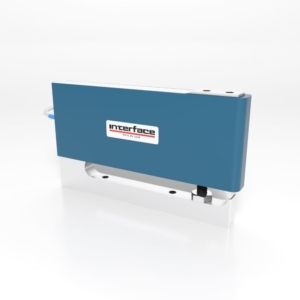

The SPI Low Capacity Platform Scale Load Cell is designed to be a high-precision platform load cell. This product is compensated for off-center loading and is available in capacities ranging from 3 to 15 lbf (13.34 to 66.72 N).

The SPI Low Capacity Platform Scale Load Cell is designed to be a high-precision platform load cell. This product is compensated for off-center loading and is available in capacities ranging from 3 to 15 lbf (13.34 to 66.72 N).

Interface SPI cells with capacities of 3 lbf, 7.5 lbf, and 15 lbf contain their internal compression overload stop, which is adjusted at the factory to protect the cell up to four times the rated capacity. These cells have an additional bar under the lower surface to provide a mount for the internal compression stop screw.

The center bar, containing the gages, is a bending beam. It is supported by the outer frame containing four thin flexure points, two on the top and two on the bottom, to provide mechanical strength for side and moment loads. This construction provides the superior moment canceling capability of the SPI, which ensures a consistent weight indication anywhere within the weigh pan size limits.

The SPI High Capacity Platform Scale Load Cell is a high-precision sensor. This product is compensated for off-center loading and is available in capacities ranging from 25 to 150 lbf (111.2 to 667.2 N). These SPI load cells can be protected by placing hard stops under the corners of a weigh pan to catch the pan before excessive deflection damages the SPI cell.

Interface’s popular miniature MBI Overload Protected Miniature Beam Load Cell is a compact-sized SPI. The MBI has better resistance to off-axis loads than similar load cells and is fatigue-rated. This product has capacities from 2 to 10 lbf (10 to 50 N).

Interface’s popular miniature MBI Overload Protected Miniature Beam Load Cell is a compact-sized SPI. The MBI has better resistance to off-axis loads than similar load cells and is fatigue-rated. This product has capacities from 2 to 10 lbf (10 to 50 N).

Reasons Why You Might Choose Single Point Impact Load Cells

- Precise Measurements – SPI load cells are designed to measure impact forces or loads exerted on a single point accurately and precisely. This precision is crucial in applications requiring precise force measurement for quality control, safety, or compliance reasons.

- Versatility – SPI load cells can be used in various industries, including material testing, impact testing, product durability testing, and process control. Their versatility makes them suitable for diverse applications requiring precise force measurement.

- Compact Design – SPI load cells are typically compact and lightweight, making them easily integrated into different systems and applications. Their small form factor allows for flexible installation and minimizes space requirements.

- Durability – SPI load cells are often constructed from robust materials such as stainless steel or aluminum, ensuring durability and reliability even in harsh operating environments. They are designed to withstand impact forces, vibrations, and other challenging conditions encountered in industrial settings.

- Cost-Effectiveness – Despite their high precision and performance capabilities, SPI load cells are often cost-effective compared to other load cells, making them a cost-efficient solution for many applications.

SPI load cells are often used in industrial settings for applications such as materials testing, impact testing, product durability testing, and quality control processes where the force exerted at a single point needs to be accurately measured. They are also utilized in various machinery and equipment to monitor loads and ensure safe operation. The SPI is popular with universities and test labs due to its precision and ruggedness.

If you are exploring single point impact cells, contact Interface application engineers to see how we can help you with your project or program.