Increasing demand for quality, accurate and reliable sensor technologies is global. Interface products are used on every continent and across all types of industries. As manufacturers and product innovators make advances in what they build and test, there is a direct correlation to the growth in precision test and measurement tool requirements we supply.

Increasing demand for quality, accurate and reliable sensor technologies is global. Interface products are used on every continent and across all types of industries. As manufacturers and product innovators make advances in what they build and test, there is a direct correlation to the growth in precision test and measurement tool requirements we supply.

The overall sensor market in 2022 is expected to continue its fast past growth, estimated between 8-12% across all types of sensors. In force measurement, this pace is consistent with the experience in the global markets we serve in Africa, Asia, Australia and Oceania, Europe, Middle East, South and North America.

Represented by hundreds of sensors experts around the world, Interface distributors continue to experience growth in market share and Interface product users. In fact, Interface’s fastest growing markets are represented in our global network. Solutions that utilize our precision load cells, torque transducers, multi-axis load cells and instrumentation are all experiencing high growth worldwide.

What is impacting the greatest international growth for all types of sensors technologies? According to market analysis and based on Interface’s experience, it’s being fed by:

- Miniaturization of Products and Sensors Used in Testing and OEMs

- Industrial Automation and Robotics

- Innovation in Aerospace and Automotive

- IoT – Internet of Things

Our direct experience in demand for Interface solutions outside of the US is related to these areas and specifically new products and expanding use cases. First, we recently launched our Global G Series products to meet this demand. This specialty product is sold exclusively outside the US. These products are designed and manufactured in the International System of Units (SI), with the same precision and accuracy of all Interface products.

The Global G Series is a global standard product line that is designed for applications that require miniature load cells and for OEM solutions used for automation of machines and components. The markets that are experiencing the highest growth internationally include:

For example, innovative markets like electric vehicles and hydro-electric energy are growing rapidly domestically and in international markets. These industries rely on force testing to optimize these new technologies.

The Asia-Pacific market is currently our fastest growing market. Interface provides products for this market across all industries including automotive, aerospace, test and measurement and more. As mentioned above, the alternative energy, aerospace and electric vehicle market is a big area for Interface and the Asia-Pacific plays a big role in these areas.

Electric vehicle design and manufacturing requires a precise level of accuracy to improve energy efficiency, minimize weight and maximize vehicle range. For instance, battery technology is a major global focus; therefore, maximizing power output using force testing is the key to improving vehicle design. To achieve this, test and measurement solutions need to be as accurate as possible. Interface also provides high accuracy torque transducers, load cells, load washers and more for two areas of electric vehicle testing: laboratory testing to optimize system performance and production testing to ensure product quality.

Another application for force measurement in Europe is force testing on off-shore hydro-electric power plants. This is a great fit for Interface because we have developed an entire lineup of load cells and other products that are submersible. For this project specifically, we provided submersible WMC load cells. This is one example of an innovative application for renewable energies, and this is another market that is growing rapidly both domestically and internationally.

One of the consistent top selling products in both regions and industries are wireless load cells. In our 2022 Test and Measurement Industry Trends blog, detailed some of this growing demand for wireless force measurement solutions. Wireless systems are helping manufacturers simplify the integration process and create a cleaner safer test environment with far less wiring. It is especially helpful in industries like aerospace or automotive, where large factories want to transmit data across the facility without needing a mess of wires getting in the way.

For wireless needs, Interface supplies its Wireless Telemetry System (WTS) which offers sensor transmitters, receivers, and displays. High accuracy, high quality measurement is interfaced with simple yet powerful configuration and monitoring software and gives sensor manufacturers and integrators the complete flexibility to build their own sensor modules around it. The system easily replaces wired systems, reducing installation and maintenance costs.

One area that Interface is also investing in internally is recalibration services to serve all customers across the world. Many of our customers are becoming more aware of and utilizing these services, as we are continuing to grow this capability amongst international customers who are utilizing Interface products for the first time.

Interface’s presence in the international market is growing quickly. Interface is looking forward to seeing where and how we can supply the best in force measurement solutions to enable innovation around the world.

Source: Tyler Pettit, Application Engineer International Markets

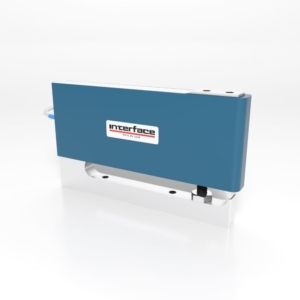

A single point impact load cell (SPI) is a sensor that measures the impact force or load accurately applied to the force or weight exerted on a single point. SPI load cells offer precise and reliable measurements of impact forces or loads, making them valuable tools in various industries and applications.

A single point impact load cell (SPI) is a sensor that measures the impact force or load accurately applied to the force or weight exerted on a single point. SPI load cells offer precise and reliable measurements of impact forces or loads, making them valuable tools in various industries and applications. The

The  Interface’s popular miniature

Interface’s popular miniature  Interface solutions test and measure the performance of all types of machines, from heavy-duty extraction equipment to tiny digits on robotic arms.

Interface solutions test and measure the performance of all types of machines, from heavy-duty extraction equipment to tiny digits on robotic arms.  Interface recently hosted an online technical seminar,

Interface recently hosted an online technical seminar,  Interface offers wireless LowProfiles, Mini Load Cells, Load Shackles, and Torque Transducers. Interface has the experience and engineering capabilities to design most of our sensors for wireless use. Commonly used Interface wireless load cells are our

Interface offers wireless LowProfiles, Mini Load Cells, Load Shackles, and Torque Transducers. Interface has the experience and engineering capabilities to design most of our sensors for wireless use. Commonly used Interface wireless load cells are our

Industrial machinery plays a vital role in the global economy. It helps to improve productivity and efficiency, and it is essential to produce many of the goods we rely on daily.

Industrial machinery plays a vital role in the global economy. It helps to improve productivity and efficiency, and it is essential to produce many of the goods we rely on daily. Vertical farming is a method of producing crops in vertically stacked layers, typically in indoor environments such as warehouses or greenhouses. This innovative

Vertical farming is a method of producing crops in vertically stacked layers, typically in indoor environments such as warehouses or greenhouses. This innovative