Load Cell Basics Sensor Specifications

When selecting a load cell, it’s critical to understand the major factors impacting sensor accuracy. These factors are determined by the materials and components used in the construction of the load cell, the calibration, instrumentation, the accessories such as cables, and mounting installation. Each must be considered in the specific use cases for the load cells.

During our virtual event, Load Cell Basics, applications expert Keith Skidmore detailed everything you need to know about load cells and how to choose the right load cell. First, Keith highlighted four vital application considerations:

Mechanical – Dimensions and Mounting

Electrical – Output and Excitation

Environmental – Temperature and Moisture

Performance – Accuracy and Thermals

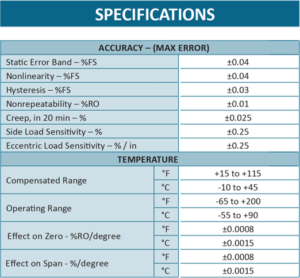

Taking a deeper dive into performance, an important consideration when selecting your load cell are the sensor specifications and how they impact accuracy. The sensor specifications relate to the max error of various parameters. The specifications are always included in product spec sheets and are expressed using the following values – %FS, %RO, %, %/°F, time-related. Specifications listed relate to the max error for accuracy and temperature.

Interface provides all sensor specification data for our load cells in the product datasheets found on each product page for easy download.

The information we provide for every load cell typically includes:

Accuracy:

- Static Error Band

- Non-linearity

- Hysteresis

- Non-repeatability

- Creep

- Side Load Sensitivity

- Eccentric Load Sensitivity

Temperature:

- Compensated Range

- Operating Range

- Effect on Zero

- Effect on Span

Further definitions can be found in our online technical glossary. Here are a few that we highlighted in the Load Cell Basics webinar.

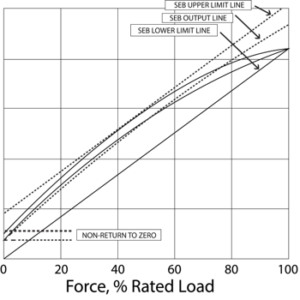

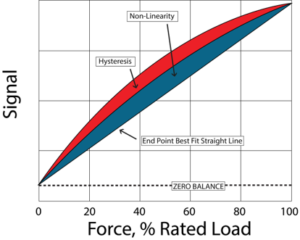

Static Error Band: A band encompassing all points on the ascending and descending curves centered on the best fit straight line. It is expressed in units of %FS.

SEB Output: The output at capacity based on the best fit straight line.

Non-repeatability: The maximum difference between output readings for repeated loadings under IDENTICAL LOADING AND ENVIRONMENTAL CONDITIONS. In practice, there are many factors that affect repeatability that ARE NOT included in the non-repeatability specification. It is normally expressed in units of %RO.

Non-linearity: The difference in the output from a straight line. It is normally expressed in units of %FS.

Hysteresis: The difference in the ascending versus descending curves. This is normally expressed in units of %F.

Understanding these factors and the maximum error for your specific project is critical to selecting a load cell and getting the best possible data out of it.

Review the product specs on each datasheet or our product catalogs to learn more about sensor specifications for load cells. For additional help, call to speak with our application engineers at 888-557-2533.

Request a Quote from Interface, The World Leader in Force Measurement Solutions

To view additional online events, please go to our events page.