Bending Beam Load Cell Basics

Bending beam load cells are a versatile and cost-effective solution for many weighing and force measurement applications. These types of miniature load cells are small in dimension, which makes them ideal solutions for compact testing environments and for embedding into machines or products for continuous performance measurement.

Bending beam load cells are a versatile and cost-effective solution for many weighing and force measurement applications. These types of miniature load cells are small in dimension, which makes them ideal solutions for compact testing environments and for embedding into machines or products for continuous performance measurement.

The use of bending beam load cells expands across industries and applications, for weighing scales, medical devices, industrial process controls, robotic designs, packaging machinery and civil engineering projects.

How Bending Beam Load Cells Work

A bending beam load cell converts a force applied to it into an electrical signal by measuring the flexure of the beam. This is done by attaching strain gages to the beam. When the beam bends, the strain gages change their resistance, which is then converted into an electrical signal by a Wheatstone bridge circuit. The output signal is proportional to the applied load.

The bending beam load cell is bolted to a support through the two mounting holes. Under the covers, you can see the large hole bored through the beam. This forms thin sections at the top and bottom surface, which concentrate the forces into the area where Interface’s proprietary strain gages are mounted on the top and bottom faces of the beam. The gages may be mounted on the outside surface, as shown, or inside the large hole.

The compression load is applied at the end opposite from the two mounting holes, usually onto a load button that the user inserts in the loading hole.

MB Miniature Beam Load Cell

The Interface Model MB is a miniature beam load cell used in test machines and a variety of low capacity applications.

- Standard Capacities are 5 to 250 lbf (22.2 N to 1.11 kN)

- Proprietary Interface temperature compensated strain gages

- Performance to 0.03%

- Low height – 0.99 in (25.1 mm)

- Eccentric load compensated

- ±0.0008% /˚F – max temperature effect on output

- Low deflection

MBI Overload Protected Miniature Beam Load Cell

Interface’s Model MBI Overload Protected Miniature Beam Load Cell has better resistance to off-axis loads then other similar load cells and is fatigue rated.

Interface’s Model MBI Overload Protected Miniature Beam Load Cell has better resistance to off-axis loads then other similar load cells and is fatigue rated.

- Standard capacities from 2 to 10 lbf (10 to 50 N)

- Proprietary Interface temperature compensated strain gages

- Performance to 0.03%

- Low height – 1in max

- ±0.0008% /˚F – max temperature effect on output

- 10x overload protection

MBP Overload Protected Miniature Beam Load Cell

Our Model MBP series Mini load cells provide a similar performance to Model MB series with the added safeguard of internal overload protection. This patented overload protection is accomplished via hard stops that are EDM machined into the load cell flexure. This provides a greater overload protection (2.5-10lbf ±1000% of full scale capacity, 100 N ±500% of full scale capacity), giving the user added protection in more severe applications.

Our Model MBP series Mini load cells provide a similar performance to Model MB series with the added safeguard of internal overload protection. This patented overload protection is accomplished via hard stops that are EDM machined into the load cell flexure. This provides a greater overload protection (2.5-10lbf ±1000% of full scale capacity, 100 N ±500% of full scale capacity), giving the user added protection in more severe applications.

- Standard capacities from 2 to 10 lbf (10 to 50 N)

- Proprietary Interface temperature compensated strain gages

- 10x overload protection

- Low height – 0.99 in (25.1 mm)

- ±0.0008% /˚F temp. effect on output

- 5′ Integral Cable (custom lengths available upon request)

- NIST Traceable Calibration Certificate

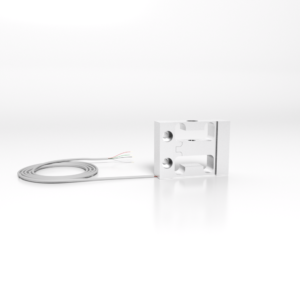

MBS Parallelogram Load Cell

The Interface MBS Parallelogram load cell is made of lightweight aluminum construction and highly suitable for medical and robotics applications.

The Interface MBS Parallelogram load cell is made of lightweight aluminum construction and highly suitable for medical and robotics applications.

- Capacities from 2.2 to 10 lbf (9.8 to 44.5 N)

- Lightweight

- Nonlinearity error 0.02% FS

- Ideal for OEM applications

Double Bending Beam Cells

A very useful variation on the bending beam design is achieved by forming two bending beams into one cell. This allows the loading fixtures to be attached at the threaded holes on the center line, between the beams, which makes the sensitive axis pass through the cell on a single line of action.

Bending Beam Load Cell Applications

Material testing is a common application for bending beam load cells. This type of miniature load cell measures the forces applied to materials with a high degree of accuracy to determine stiffness, strength and durability of the specimen.

It is quite common to find bending beam load cells in industrial automation machines and robots to precisely measure the forces required for control, safety and efficiency. In robotics specifically, bending beam load cells will measure the force applied to the robot’s arms and grippers. The data is used to control the robot’s movements and to ensure that it is not damaging the objects it is handling.

Aerospace engineering have long used bending beam load cells in design, testing and manufacturing of aircraft and spacecraft. Automotive engineering use bending beam load cells to design and test vehicles for safety and reliability.

Due to Interface’s ability to custom design bending beam solutions that meet strict size, capacity and accuracy requirements, our products are commonly used in medical and healthcare applications.

Bending Beam Application for Medical Device Testing

In this application, the medical device product lab needs to apply known forces to stent and catheters to ensure they pass all necessary strength and flexibility testing. MBP Overload Protected Beam Miniature Load Cell is placed behind the guide wire for the stent or catheter. The motor will spin the linear drive, push the load cell, and guide the wire through the testing maze. The bending beam load cell connects to the DIG-USB PC Interface Module to record and store testing data for analysis. Read more.

Bending Beam Application for Vertical Farming

Vertical farming is the production of produce in a vertical manner using smart technology systems, while indoors using an irrigation system. A wireless force measurement solution is needed to monitor the amount of water being used, to ensure the produce is being watered just the right amount. Interface suggests installing four MBI Overload Protected Miniature Beam Load Cells under each corner of the trays of the produce to accurate measure the weight during watering. A JB104SS 4-Channel Stainless Steel Junction Box connects to each bending beam cell and to a WTS-AM-1E acquisition module. The device wirelessly transmits the sum weight to the WTS-BS-1-HA Wireless Handheld Display for multiple transmitters, and the WTS-BS-6 Wireless Telemetry Dongle Base Station. Interface’s Wireless Telemetry System monitored and weighed the amount of water being used on the produce in this vertical farming system to increase yield and conversation. Read more here.

Additional Resources

The Basics Of Shear And Bending Beams

Interface Mini™ Load Cell Selection Guide