Torque Transducers 101

Torque is defined as the rotational equivalent of linear force. It’s a measure of how much a force acting on an object causes that object to rotate. This is one of the key measurements for engineers doing design, test, and manufacturing. It’s critical to understand how to identify torque if you’re doing product development with rotating systems such as engines, crankshafts, gearboxes, transmissions, and rotors.

Torque is defined as the rotational equivalent of linear force. It’s a measure of how much a force acting on an object causes that object to rotate. This is one of the key measurements for engineers doing design, test, and manufacturing. It’s critical to understand how to identify torque if you’re doing product development with rotating systems such as engines, crankshafts, gearboxes, transmissions, and rotors.

Interface develops more than 50 different kinds of reaction and rotary torque transducers, as well as custom transducers for our customers. All our torque transducers also referred to as torque sensors, are precision-machined and use our proprietary torque sensors for the most accurate data possible, quality and reliability.

Here are some frequently asked questions and details about torque transducers, including key terms and descriptions of reaction versus rotary, shaft and flange style torque, couplings, and floating and fixed mounts.

What is a torque sensor (transducer)?

A torque sensor is a transducer that converts a torsional mechanical input into an electrical output signal.

Reaction versus Rotary

There are two types of transducers that Interface sells, reaction and rotary transducers. Reaction torque transducers measure static torque, or torque without rotating, and are widely used in process control and testing. Rotary torque transducers like AxialTQ measure dynamic force and are used in applications where the torque transducer must rotate when attached to a spinning shaft. A rotary torque transducer provides a method of getting the signal off of the rotating element without an attached cable, while a reaction transducer uses an attached cable.

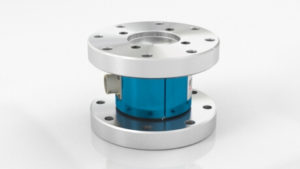

Shaft and Flange Style Torque

The shaft or flange is the component taking the torque measurement. Shaft style torque offers convenient mounting and has a longer installed length than flange style. It comes in two different versions, smooth and keyed shafts. A smooth shaft provides ease of assembly and disassembly, with zero backlash. Keyed style shafts are simple and less expensive; however, they can suffer from wear due to backlash. The flange style is typically shorter than the shaft style and has pilots on its flange face as a centering feature. This style has better resistance to overhung moments and can be more convenient to mount.

Coupling

Couplings are a critical component to the torque transducer that ensures the isolation of torque loads. Couplings should be used in all applications, and the selection of the coupling type is based on the speed of the application. For higher speed applications, you will want to look for high-quality couplings. The coupling helps to prevent error and/or damage from extraneous loads.

Floating and Fixed Mounts

There are two common types of torque transducer mounts, floating and fixed mounts. For high-speed applications, fixed and supporting mounting is mandatory. For safety reasons, floating mounts should only be used for low-speed applications. In floating mounts, the sensor is supported only by the drive and load side connectors, and a flexible strap keeps the sensor from rotating. Fixed mounts apply only to sensors with bearings, and it involves attaching the sensor housing to fixed support for added stability.

For more information on Interface’s wide selection of torque transducers, please visit www.interfaceforce.com/product-category/torque-transducers/.