Fitness Equipment

Fitness Equipment

Fitness equipment manufacturers are installing sensors of all types into their equipment to measure various forces and provide fitness data to the user, trainers, physical therapists, and doctors to monitor movement and actions.

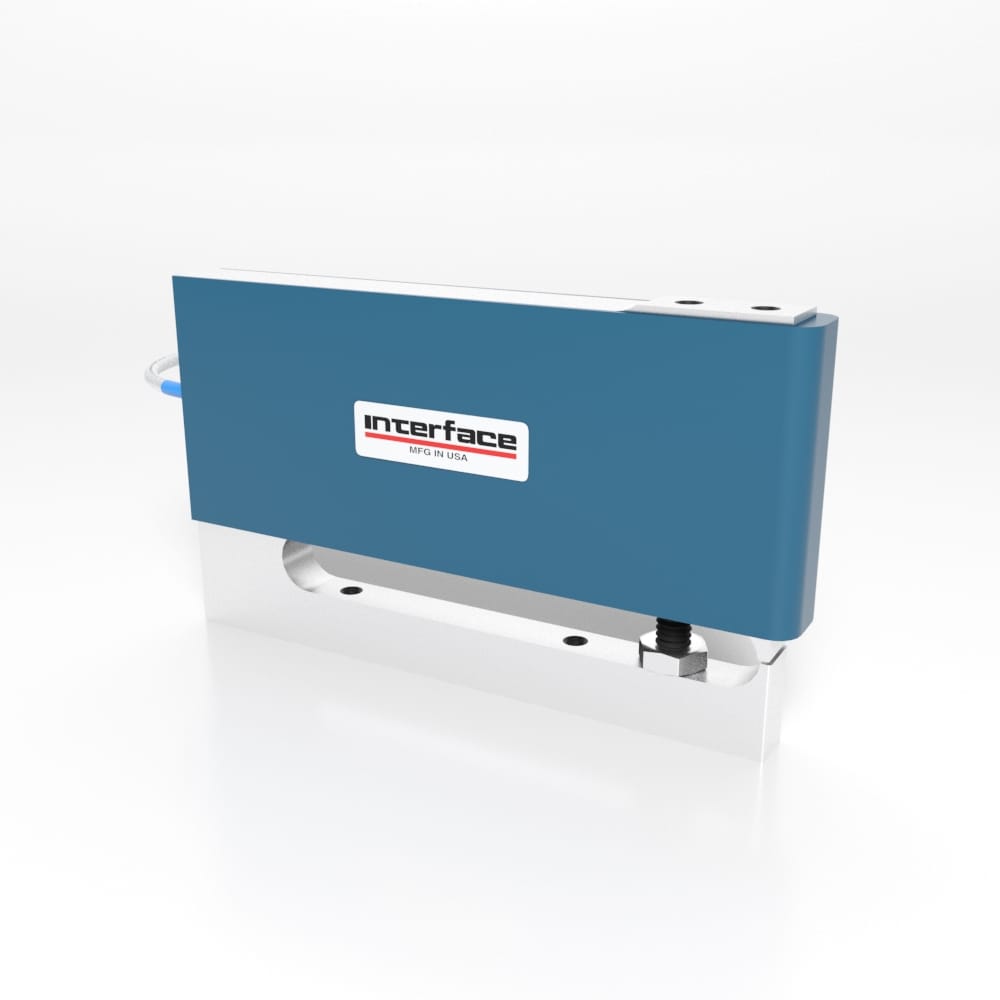

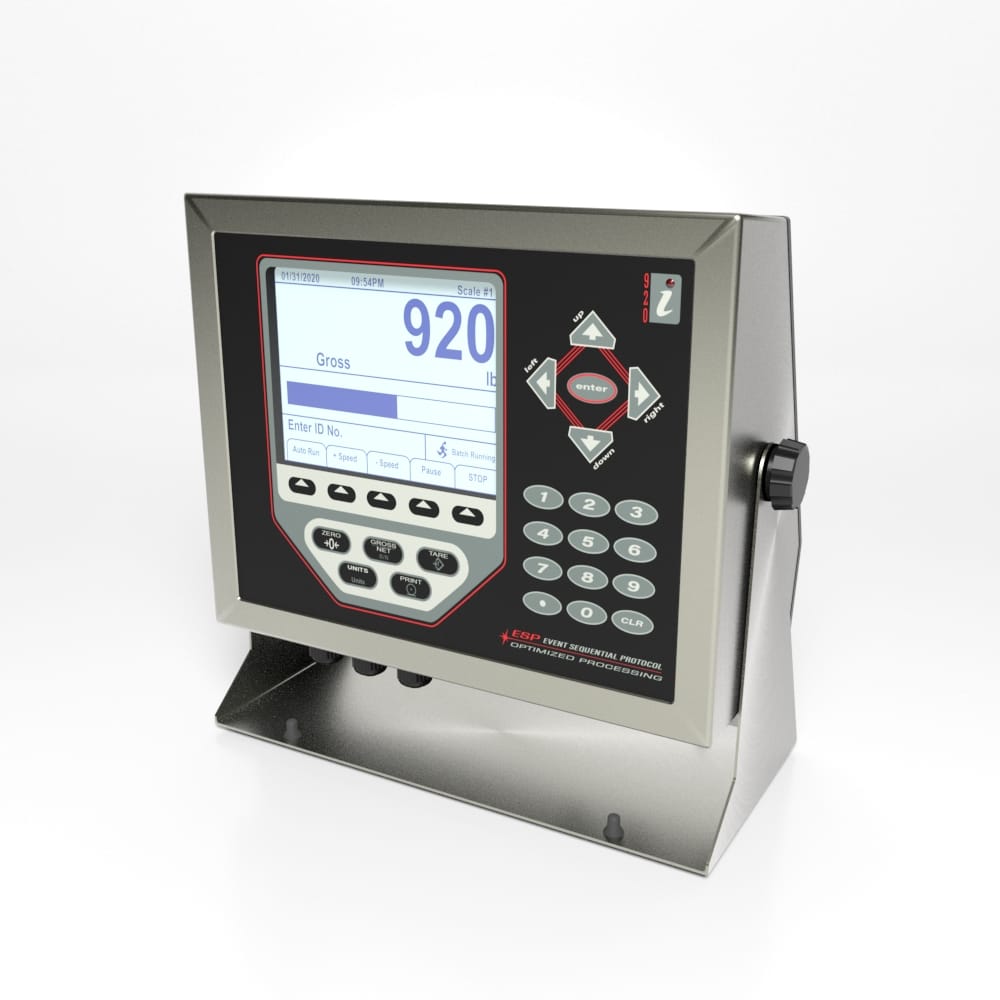

Interface’s load cells, torque transducers, multi-axis sensor and instrumentation are currently utilized in the testing, production, and continuous monitoring of modern exercise equipment. Demand for instantaneous feedback by consumers is part of the requirement sensor-based systems that accurately measure weight, torque, and force in motion.

Interface Mini Load Cells are designed for easy integration into fitness equipment, for all phases from R&D to consumer use. The size, capacity and low cost provides a sensible OEM option to activate the equipment for real-time feedback and performance monitoring. The results are increased use, higher satisfaction by the user, accuracy in measurement, better feedback, increased quality, and enhanced safety features.

Types of Fitness Equipment Benefitting from Interface Measurement Solutions

The global fitness market requires a trusted and proven measurement solutions partner. The industry is looking at consistent growth over the next few years. The global fitness equipment market is estimated to be over $16B and growing at 5.3% CAGR from 2023 to 2030.

Interface load cells are being used to assess different running techniques and monitor the progress of rehabilitation exercise. Interface’s sensors provide accurate data for all types of user profiles in the fitness industry such as strength variability, weights, and distinct experience levels.

Fitness_Infographic_Poster

Water Bottle Dispensing and Weighing

Water Bottle Dispensing and Weighing

Interface Solutions for Safety and Regulation Testing and Monitoring

/in Blog /by Jamie GlassAmong the many challenges we help to solve, safety and the stringent requirements for helping to make products safer for all types of users is top of the list. Interface’s solutions are known for quality and accuracy, which are at […]

Taking Measure of Miniature Load Cells Webinar

/in Virtual Event /by Jamie GlassInterface force measurement engineers and solution experts host an online discussion focused on products used to withstand one or more conditions related to temperature, cycling, moisture, environmental stresses. Learn about Interface’s stainless steel load cells, environmentally sealed options, submersible test and measurement products, enclosures, wireless capabilities, load pins, intrinsically safe products. We detail solutions used for all types of applications used in industries that include medical device, aerospace and defense, industrial automation, infrastructure, maritime and general test & measurement. We discuss sensors models, capabilities, features and FAQs. We dive into use cases, tips, measurement know-how and OEM products.

Interface Solutions for Consumer Products

/in Blog /by Jamie GlassInterface’s force measurement solutions affect every industry and all types of products. Chances are that the everyday consumer has purchased and used something evaluated with or utilizing an embedded force sensor. In fact, Interface has a long history in providing […]

Interface Solutions in the World of Sports

/in Blog /by Jamie GlassWith our headquarters in the golf capitol of the U.S., it is easy to see why Interface test and measurement solutions rank top for engineers and golf manufacturers to test the force of golf balls, range equipment, clubs, and even […]

Fitness Equipment Makers Require Extreme Accuracy

/in Blog /by Jamie GlassInterface’s specialty is building solutions for the testing and monitoring of parts and total systems that move and create force. One of the industries where this is critical is the fitness industry. Equipment and fitness machines, whether designed for in-home […]

Users of Interface Test and Measurement Products

/in Blog /by Jamie GlassInterface has a long history working with several types of users that rely on our products for test and measurement. From pioneering engineers working in campus labs to ground-breaking scientists and innovators finding solutions to complex problems. We often share […]

Interface Helps Power the World

/in Blog /by Jamie GlassAs technology and infrastructure have advanced to accommodate various forms of energy collection, the role of force measurement in the test and manufacturing of these machines has grown significantly. As a precision force measurement solutions provider, Interface has been a […]

Interface Plays a Role in Testing Bicycles

/in Blog /by Brian JohnsonInterface sensors are used in a never-ending list of products, from heavy machinery to miniature medical devices. In the spirit of the Olympics, we thought we would share how our force and torque technologies are used in the test and […]

Interface Forms Partnership with Manufacturers’ Representative Hill and Company

/in Blog /by Brian JohnsonIn a move that expands Interface’s ability and expertise in serving our customers across a wide range of industries in the Midwest, Interface today announced a new partnership with manufacturers’ representative Hill and Company. Hill and Company brings more than […]

Applications for Consumer Products and Packaging

/in Blog /by Brian JohnsonWhen we think about force measurement and its relation to product development, we often consider the aerospace, automotive or industrial industry. However, many of Interface’s customers use load cells and torque transducers to test and develop machinery used for consumer […]