Understanding One-Cell Force Measurement Systems

When it comes to load cells and force measurement systems used to test and validate product designs, the options for different configurations is nearly endless. In fact, Interface has tens of thousands of force measurement products in standard, modified and custom-made configurations.

When it comes to load cells and force measurement systems used to test and validate product designs, the options for different configurations is nearly endless. In fact, Interface has tens of thousands of force measurement products in standard, modified and custom-made configurations.

In our recent post, Considerations for Steel, Stainless Steel and Aluminum Load Cells, we detailed materials used in load cell construction. These considerations are important based on the project specifications for accuracy, quality and reliability in test and measurement.

Similarly, understanding the system configuration is another critically important factor to setting up the correct test for receiving accurate data. A simple system configuration used for less-complex testing is known as one-cell or single load cell system. They are popular for performance and durability testing.

How do one-cell systems work and what are the benefits and trade-offs?

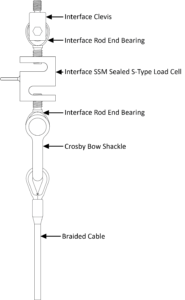

One-cell systems are developed by using a tension cell and mounting it through a rod end bearing and clevises. If the cell is properly oriented with the dead end going to the support, the only other major consideration for this system is the elimination or reduction of possible parallel load paths. This type of simple system is attractive to some testing engineers and product designers because it is cost effective and can provide very accurate measurements when using Interface precision load cells. It is important that the load meets the criteria for the test system.

One-cell systems are developed by using a tension cell and mounting it through a rod end bearing and clevises. If the cell is properly oriented with the dead end going to the support, the only other major consideration for this system is the elimination or reduction of possible parallel load paths. This type of simple system is attractive to some testing engineers and product designers because it is cost effective and can provide very accurate measurements when using Interface precision load cells. It is important that the load meets the criteria for the test system.

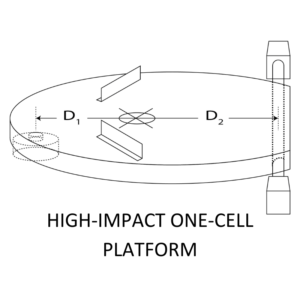

In this figure, it shows a high-impact one-cell system platform. This one-cell system can withstand the high impact of rough treatment from certain applications such as large drums, LPG tanks and more.

In this figure, it shows a high-impact one-cell system platform. This one-cell system can withstand the high impact of rough treatment from certain applications such as large drums, LPG tanks and more.

The downside to using a one-cell system is that the center of gravity of the load must be placed directly on the mark for the system to work properly. However, this can be accounted for by positioning the fences as shown in the high-impact one-cell platform diagram, so that the center of gravity is located properly when the application you are measuring is shoved up against fences.

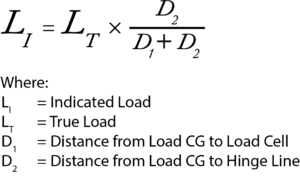

The actual load at the center of gravity for your application will be factored by the lever arm (as shown below):

The one-cell system works simply because the location of the center of gravity is under control. If the force on the primary axis of the load cell bears the same relation to the location of the center of gravity and the load under all conditions, the scaling will be correct. Whether using a one-cell or two-cell system, the system must be designed to retain its integrity.

This has been a brief overview of a one-cell system, which is detailed in Interface’s Load Cell Field Guide.

To learn more about these systems and to determine if your application test can utilize the simplicity and cost savings of a one-cell or two-cell system, contact our systems experts and application engineers.