Interface Weighing Solutions and Complete Systems

Sensors are commonly used for weighing applications throughout the product life cycle, from R&D to distribution. Sensors are used for weighing individual parts or components, inside equipment and machines for measuring weight during assembly and production, weighing ingredients, and weighing final products during distribution and transportation. Interface provides a range of weighing solutions for these use cases, including individual measurement devices, instrumentation, and complete systems to manage large and small projects.

Interface supplies highly accurate and reliable load cells and sensor technologies for weighing and scale solutions, including complete weighing systems. Weighing and scales must be dependable and always provide correct data. That is why Interface’s precision sensors and instrumentation are preferred for weighing systems. To outline our breadth of this product line including complete systems, we recently introduced a new Weighing Solutions Overview.

Interface Weighing Solution Products

- LowProfile® Load Cells

- Load Beam Load Cells

- Platform Scale Load Cells

- Load Pins

- Tension Link and Wireless Link Load Cells

- Load Shackles and Wireless Load Shackles

- Pillow Block Load Cells

- WeighCheck™ Load Cells

- Indicators

- Weighing Instrumentation

- Wireless and Bluetooth Sensors and Accessories

- Instrumentation Software

Interface offers weighing solutions that are standard products and engineered to order for weighing use cases. This includes our 2023 Weighing Review Award nominated A4200 Weighcheck Load Cells.

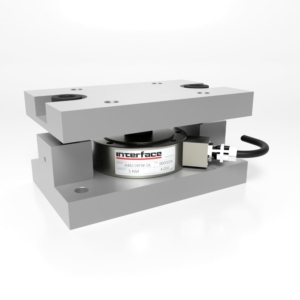

Interface A4600 WeighCheck™ Load Cells in stainless steel and A4200 WeighCheck Load Cells, which is zinc plated, are both high accuracy force measurement weighing solutions. Manufactured and designed by Interface engineers, these exclusive Interface products are specifically designed for tank weighing, where it is necessary to accommodate expansion and contraction of the tank. Interface has expanded with new model options that include signal conditioning features, including customized IO-Link Digital and 3-Wire options. The newly introduced customized A4200 and A4600 3-Wire Amplified Load Cells provide an internally amplified low profile load cell with a voltage or mA signal. This option eliminates the need for an external signal conditioner and comes scaled to the load cell and ready to use.

Interface A4600 WeighCheck™ Load Cells in stainless steel and A4200 WeighCheck Load Cells, which is zinc plated, are both high accuracy force measurement weighing solutions. Manufactured and designed by Interface engineers, these exclusive Interface products are specifically designed for tank weighing, where it is necessary to accommodate expansion and contraction of the tank. Interface has expanded with new model options that include signal conditioning features, including customized IO-Link Digital and 3-Wire options. The newly introduced customized A4200 and A4600 3-Wire Amplified Load Cells provide an internally amplified low profile load cell with a voltage or mA signal. This option eliminates the need for an external signal conditioner and comes scaled to the load cell and ready to use.

Standard A4600 and A4200 WeighCheck Load Cell features include:

- Capacity ranges from 2.5K to 50K lbf (11.1 to 222 kN)

- High output – 4 mV/V

- Self-centering in all directions

- High safe side load – to 400%

- Standardized output – ±0.1%

- Zinc plated (A4200) or stainless steel (A4600)

- Factory assembled for easy field installation

- Static, dynamic and in-motion capabilities

- Low height – 4.0 in (101.6 mm) for 2.5K, 5K, 10K (11.1, 22.2, 44.5 kN); 5.0 in (127 mm) for 25K, 50K lbf (111, 222 kN)

Interface offers fully engineered to order and custom options to our WeighCheck load cell models that include our new A4200 and A4600 IO-Link Digital Load Cells with an industry stand M12 connector. IO-Link, a communication protocol used in industrial automation applications to connect sensors and actuators to control systems has multiple benefits. These include increased flexibility, enhanced diagnostics, simplified wiring, improved efficiency, and lower costs.

Engineering Insights to Build Complete Weighing Systems

Interface’s weighing solutions include single and multiple sensor systems, depending on the exact application requirements. Important for this type of test and measurement, we have wired and wireless sensors, data acquisition systems, weight indicators, displays, and transmitters, software solutions and accessories. A review of many of these products and applications are detailed in our popular recorded Weighing Your Options Webinar.

When helping to build customized full weighing system solutions, there is additional configuration and engineering work that goes into delivering the system. One of the most important aspects of building a system is load cell trimming. Excitation trimming the old way adds resistance to the excitation. The system load cell with the lowest output receives the full excitation voltage, while the other system load cells receive proportionately smaller excitation voltages. This creates matched outputs for all load cells in the system.

Signal trimming is the most common and popular type of trimming because it is the easiest to use. It involves adding a relatively high parallel resistance between the signal of each load cell, which creates a leakage path that diverts some of the available load cell signal away from the indicator. More load cell signal will be available to the indicator as parallel resistance increases.

Weighing Applications

Inventive Agriculture Monitoring and Weighing Solutions

IoT Waste Management Container Weighing App Note

Snack Weighing and Packaging Machine

Weighing Your Options Webinar Recap

Interface Weighing Solutions Overview

Weighing Solutions Brochure