Interface Submersible Load Cells

Interface load cells and force measurement devices are designed for all types of environments. Providing solutions to those working in and serving the maritime industry is our priority. Interface offers products engineered to provide accurate and reliable measurement data near shore, offshore and underwater.

Interface load cells and force measurement devices are designed for all types of environments. Providing solutions to those working in and serving the maritime industry is our priority. Interface offers products engineered to provide accurate and reliable measurement data near shore, offshore and underwater.

Interface offers a variety of force measurement products that are designed for harsh environments and submersible use cases, both for single tests as well as designed into components and manufactured goods. Often these products are used for continuous regulatory and safety monitoring applications.

Interface submersible load cells and specialized sensors can transmit data through underwater applications and harsh weather conditions. These load cells can survive through underwater submersions at different capacities, and relay information to surface level or underwater devices. Interface load cells are used to regulate harsh maritime situations such as underwater tension lines, underwater drilling, as well as for storm and tsunami monitoring.

Submersible load cells are available in a range of capacities and configurations, from miniature load cells to load shackles. Interface provides standard submersible products as well as custom solutions that are designed to the exact specification. We also provide instrumentation solutions that can be fully sealed with wireless components. Working with our expert engineers, we can provide waterproof housing of sensors, including for our line of LowProfile Load Cells and Interface Multi-Axis Sensors to be used in harsh environments and underwater.

An example of a submersible product is the Interface WMC Sealed Stainless Steel Miniature Load Cell. This is an environmentally sealed tension and compression load cell useful for rugged conditions. The stainless steel construction and small size of the load cell provides many benefits when used in underwater applications. This model is available in capacities ranging from 5 to 500 lbf (22 to 2200 N) and utilizes Interface’s proprietary temperature compensated strain gages for precision measurement applications.

Another example of a submersible product is the Interface ISHK-B Load Shackle. It is designed for lifting and weighing in rugged or harsh environments, including submersible applications. The shackle pin is forged from high tensile stainless steel and high tensile carbon steel. Every load shackle is machined to exact specifications. The ISHK-B is internally gaged and the whole instrumented area is sealed to IP67 to protect it in service. The WTSSHK-B is the wireless version.

So, how do we guarantee accurate results even when these products are submerged or splashed? It’s all in the design, similar to the way new iPhones are made to be waterproof, our load cells can be designed to remain water-tight and accurate at a variety of depths. All electronic components are sealed so that data can be recorded and transmitted via waterproof cables or wirelessly.

Below are two examples of real applications that required Interface’s submersible load cell solutions.

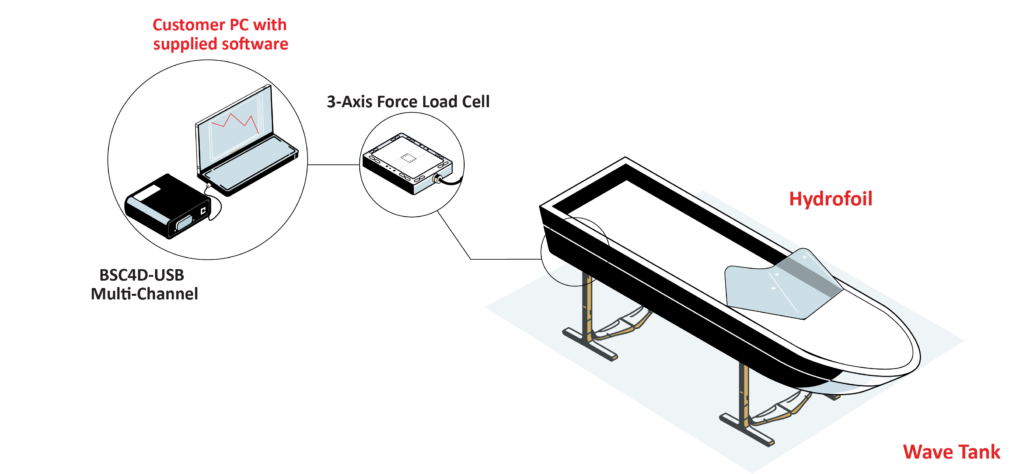

Hydrofoil Testing In Wave Tank

Hydrofoil Testing In Wave Tank

Hydrofoil design is a delicate balance between performance and complexity. Finding the right shape without using overly complex angles to achieve the desired amount of lift is crucial when designing a successful hydrofoil. Once an engineer’s concepts are ready for testing, the best force measurement equipment is required to sense the subtle differences between hydrofoil designs. Lift and drag are the most important characteristics of a hydrofoil. The 3A120 3-Axis Force Load Cell is needed to read these forces. The Fz senses lift and the Fx and Fy sense the drag. The 3-Axis Force Load Cell and bridge amplifier are protected in a waterproof housing. The watercraft is placed in a wave tank or current simulator. Using the BSC4D-USB bridge amplifier increases the visibility of the load cell’s output signals. When using the load cell and bridge amplifier, the engineers can record the real-world lift and drag forces that the hydrofoils apply on the watercraft. This data allows a more in-depth comparison of proposed hydrofoil designs to find the best model for the job. Read more about this solution here.

Mooring Line Tension Testing

Due to the changing weather conditions, mooring cable lines undergo wear and tear. A customer wanted to ensure all mooring lines for ships or vessels are securely loaded at the same tension, so that they do not risk the mooring lines breaking or causing damage. Interface’s WTSTL Wireless Tension Link Load Cells can be attached to each mooring cable while in use. Results are sent through the WTS-BS-4 USB Industrial Base Station when connected to the customer’s supplied computer. Data can also be transmitted to the WTS-BS-1-HA Handheld Display for Multiple Transmitters, giving the customer the option to view multiple mooring cable line tensions. Using this solution, the customer was able to verify the tension on multiple mooring cable lines. Thus, resulting in their ship being safely docked and secure. Read more here.

Interface expert engineers can help you design customizable solutions for all types of applications using our products designed for offshore, underwater, and splash zone locations.

Here are a few more examples of products we provide to the maritime industry.

Additional Resources

Maritime Measurement Solutions for Onshore and Submersible Applications

Deeper Dive into Maritime Solutions from Interface

CASE STUDY: Serving the Maritime Industry

Interface Explores Maritime Applications Near and Offshore