Interface’s Steering Role in All Types of Transportation

Interface serves a wide variety of industries that design and manufacture movers of people and objects. The transportation sector consists of companies that assist in the movement people or goods, as well as supporting infrastructure. Whether it is automobiles or planes, trains or helicopters, spacecraft or water vessels, Interface provides solutions to help test and measure force, weight, torque, lift and more.

Interface serves a wide variety of industries that design and manufacture movers of people and objects. The transportation sector consists of companies that assist in the movement people or goods, as well as supporting infrastructure. Whether it is automobiles or planes, trains or helicopters, spacecraft or water vessels, Interface provides solutions to help test and measure force, weight, torque, lift and more.

The safety, quality and reliability of the overall transportation industry are all important considerations in design, build and performance. Human safety being the most critical requirement of any transport vehicle or structure.

This means that stringent testing is necessary to confirm the design of every part and system on a vehicle. Force measurement sensors can used to test a wide variety of factors on every type of invention that moves or transports a person or thing. From the torque of an electrical vehicle engine to the weight distribution of an aircraft, these types of tests help to refine the designs of components, vessels, and vehicles, confirming safety and dependability.

All Interface product categories have a role in the testing of all these transportation entities. Many of our sensor technologies are also ideal for performance monitoring and integration into product designs, whether it’s for ongoing measurement of weighing ship cargo with load pins, load shackles and tension links or using our torque transducers for engine testing on e-bikes, automobiles, trucks, buses, and other transport vehicles. If it moves, it needs to be measured. Our force and torque solutions are ideal for every segment of this market sector.

Let’s take a quick tour of a few application examples that demonstrate the different products we provide that are helping get people and objects safely moving down the road, on the rails, in the air and even into space.

Wind Tunnel Testing

A major aerospace company was developing a new airplane and needed to test their scaled model for aerodynamics in a wind tunnel, by measuring loads created by lift and drag. Interface offered a Model 6A154 6-Axis Load Cell which was mounted in the floor of the wind tunnel and connected to the scaled model by a stalk. A Model BX8-AS was then connected to the sensor to collect data. The wind tunnel blew air over the scaled model creating lift and drag, which was measured and compared to the theoretical airplane models. Software in the PC converted raw data signals to actual force and torque values at the stalk. Using this solution, the company was able to analyze the collect data and made the necessary adjustments in their design to improve the aerodynamics of their theoretical airplane models. Read more.

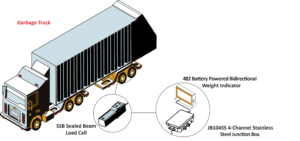

Garbage Truck On-Board Weighing

A garbage disposal company wanted to test the load capacity of their garbage truck bins so they know when it reached maximum capacity. Interface’s solution was to customize and install 4 SSB Sealed Beam Load Cells under the garbage box body, on either side. When trash continues to be piled inside the box body, it will push more force down onto the SSB Sealed Beam Load Cells. When maximum load capacity has been reached, the results can be reviewed and displayed when connected to the 482 Battery Powered Bidirectional Weight Indicator in real time. With this system, the customer was able to test the maximum load capacity of the garbage bin attached to the truck, so they know when to empty the truck’s garbage at the transfer station. Read more.

Engine Head Bolt Tightening

An industrial automation company was building an automated assembly machine for an auto manufacturing plant. They needed to tighten all head bolts on an engine on their assembly line to a specific torque value. Having the head bolts precisely and consistently tightened to the engine block is critical to the operation of the engine. Several Interface Model T33 Spindle Torque Transducers were installed in their new machine to control torque, angle, and ensure the head bolt was properly tightened. The square drive of the T33 allowed the customer to fix their tool directly to the end of the torque sensor, streamlining the installation. When the machine comes down and screws on the engine head bolts the torque and angle profile are sent to the customer’s machine controller. Based on the feedback received by the machine controller, the automation will pass the engine to the next step in the assembly line or fail and have the engine evaluated further. This allowed the customer to ensure the head bolts were correctly installed according to manufacturer specifications, producing an engine that meets performance and reliability expectations of the auto manufacturing plant. Read more.

Bicycle Load Testing

A mountain bike manufacturing company wanted a system that measures their bike frames load capacities and vibrations on the frame. They also want to ensure the bike’s high quality and frame load durability during this final step of the product testing process. Interface suggested installing Model SSMF Fatigue Rated S-Type Load Cell, connected to the WTS-AM-1E Wireless Strain Bridge, between the mountain bike’s seat and the bike frame. This will measure the vibrations and load forces applied onto the bike frame. When a heavy load is added to the seat, the SSMF Fatigue Rated S-Type Load Cell measures the vibrations and load forces applied to the bike to indicate any stress points through a number of cycles. The results will be captured by the WTS-AM-1E and transmitted to the customer’s PC using the WTS-BS-6 Wireless Telemetry Dongle Base Station. This solution helped the mountain bike manufacturing company gather highly accurate data to determine that their bikes met performance standards through this final testing cycle. Read more.

These are just a brief example of the work we do in transportation. Interface systems have been involved in projects with boats, races cars, construction vehicles and even rocket ships. Manufacturers turn to Interface because of our track record for accuracy and the transportation industry relies on this data to keep its customers safe.

For additional insights and ideas related to transportation solutions, here are a few more posts to read.

Interface Plays a Role in Testing Bicycles

Evolving Urban Mobility Sector for Test and Measurement

Interface’s Crucial Role in Vehicle and Urban Mobility Markets

Measurement Technologies for Boats, Yachts and Watercraft

Interface and The Race to Space

Driving Force in Automotive Applications

To review more application notes pertaining to transportation or to talk to an application engineer about your next project, contact us or call us at 480-948-5555.