How Santa Uses Interface Force Measurement Solutions to Expedite Delivery

It is well known that Jolly Ole Saint Nick leverages a great deal of magic to deliver countless gifts worldwide on Christmas. However, many don’t know that Santa does not do it all with the holiday magic. In fact, the science and engineering that goes into a wide variety of Santa’s many tools for delivering gifts are quite impressive!

It is well known that Jolly Ole Saint Nick leverages a great deal of magic to deliver countless gifts worldwide on Christmas. However, many don’t know that Santa does not do it all with the holiday magic. In fact, the science and engineering that goes into a wide variety of Santa’s many tools for delivering gifts are quite impressive!

With all that engineering, there is a heavy reliance of accuracy proven through rigorous test and measurement. Santa and his team confidently turn to Interface’s precision force measurement products to expedite delivery, maximize operations and packaging, quality test toys, and most importantly ensure he has absolute confidence in flight safety. How is it all possible? Lots of magical ingenuity, belief and of course, using advanced sensor technologies and instrumentation to assist in making it all happen.

Like most of our customers, we often don’t promote our custom solutions out of respect for their proprietary projects capabilities. Due to the magical capabilities that have unknown sourcing for competition, we agreed that we could reveal some of our shared secrets. Fortunately, the big guy gave us the green light to give some insight into our role in the magnificently unique present delivery machine. It should be known, our internal resources have revealed we’ve been working with special technicians in the Santa operations behind the scenes for many years.

As the world population nears 8 billion, Santa is leveraging outside experts and sources to supplement his own team’s abilities beyond reindeers and sleds, such as delivery drones. It’s a fact, Santa only works with the newest innovations. In addition, the reindeer may be magic, but the harnesses holding them to one another, and the sleigh, take careful calculations to ensure a smooth ride all night. Let’s look at a few examples of how Interface helps with all these challenges.

One disclaimer, Santa asked us not to use any real pictures from his workshop to retain the magic of Christmas and not give away trade secrets. We’ll use our app notes illustrations to paint the picture.

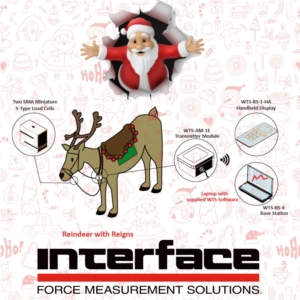

WTS Reindeer Bridle Tension System for Faster Performance

Santa came to Interface because he needed to quantify the so-called “poll pressure.” Bits designed to give strong poll pressure using simple pulley lever principles show a much-attenuated transfer of the rein tension through the bit to the poll. The attenuation is readily understood when the reindeer’s mouth is recognized as a “floating” fulcrum degrading the otherwise required fixed pivot point of an ideal lever. We suggested a WTS Reindeer Bridle Tension System, with two SMA Miniature S-Type Load Cells in both the line of the reins and that of the cheekpiece on one side of the reindeer. This is used to study the dynamic response of the cheekpiece tension to rein tension. Utilizing the Wireless Telemetry System (WTS), the valuable data can be displayed and/or recorded in real time using a PC and/or a handheld receiver. The fundamental operation of the bits could in principle be discovered on the laboratory bench. But in practice of course, the reindeer’s mouth is expected to provide the fulcrum. Within the real experimental system comprising Santa’s hands on the reins, the reindeers’ mouth, and the bit, the elasticity of the mouth provides a “floating” fulcrum and a potential source of time-lag and decoherence between the dynamic rein and cheekpiece tensions. Ultimately, this solution was applied across each of the reindeer to ensure Santa understood the pole pressure of each flying reindeer guiding his sleigh as he manned the reins.

Santa came to Interface because he needed to quantify the so-called “poll pressure.” Bits designed to give strong poll pressure using simple pulley lever principles show a much-attenuated transfer of the rein tension through the bit to the poll. The attenuation is readily understood when the reindeer’s mouth is recognized as a “floating” fulcrum degrading the otherwise required fixed pivot point of an ideal lever. We suggested a WTS Reindeer Bridle Tension System, with two SMA Miniature S-Type Load Cells in both the line of the reins and that of the cheekpiece on one side of the reindeer. This is used to study the dynamic response of the cheekpiece tension to rein tension. Utilizing the Wireless Telemetry System (WTS), the valuable data can be displayed and/or recorded in real time using a PC and/or a handheld receiver. The fundamental operation of the bits could in principle be discovered on the laboratory bench. But in practice of course, the reindeer’s mouth is expected to provide the fulcrum. Within the real experimental system comprising Santa’s hands on the reins, the reindeers’ mouth, and the bit, the elasticity of the mouth provides a “floating” fulcrum and a potential source of time-lag and decoherence between the dynamic rein and cheekpiece tensions. Ultimately, this solution was applied across each of the reindeer to ensure Santa understood the pole pressure of each flying reindeer guiding his sleigh as he manned the reins.

Expediting Holiday Gift with Santa Approved Drone Delivery

As mentioned above, Santa needed some help to ensure the growing population received presents on Christmas night, so he started to employ “delivery drones” into his process. To ensure everything went smoothly, Santa needs to weigh the payload of the package being delivered while the propeller motors compensate for weight shifting or uneven weight distribution of the package to lift and fly the package to its destination. Four Interface WMC Sealed Stainless Steel Miniature Load Cells were used to measure the weight of the payload and detect weight shifting or uneven weight distribution of the package which would signal the necessary propeller motors to compensate for an uneven weight load. The four WMC load cells accurately measured the payload weight and maintained stability of the propeller motors to safely deliver the parcel. This information was communicated to the drone’s on-board processor for monitoring and recording this information during flight. This solution has given Santa the extra hands he needs to ensure every boy and girl receives their presents in time!

As mentioned above, Santa needed some help to ensure the growing population received presents on Christmas night, so he started to employ “delivery drones” into his process. To ensure everything went smoothly, Santa needs to weigh the payload of the package being delivered while the propeller motors compensate for weight shifting or uneven weight distribution of the package to lift and fly the package to its destination. Four Interface WMC Sealed Stainless Steel Miniature Load Cells were used to measure the weight of the payload and detect weight shifting or uneven weight distribution of the package which would signal the necessary propeller motors to compensate for an uneven weight load. The four WMC load cells accurately measured the payload weight and maintained stability of the propeller motors to safely deliver the parcel. This information was communicated to the drone’s on-board processor for monitoring and recording this information during flight. This solution has given Santa the extra hands he needs to ensure every boy and girl receives their presents in time!

Production Workshop Toys and Bicycle Load Testing

Production Workshop Toys and Bicycle Load Testing

Santa’s workshop is also full of force sensing solutions for all the individual toys that need to be tested for safety and quality. One of the systems he uses measures bike frame load capacities and vibrations on the frame to ensure the bike’s high quality and frame load durability during the final step of the product testing process for children and adults receiving the bikes. Interface suggested installing Model SSMF Fatigue Rated S-Type Load Cell, connected to the WTS-AM-1E Wireless Strain Bridge, between the bike’s seat and the bike frame. This will measure the vibrations and load forces applied onto the bike frame. The results will be captured by the WTS-AM-1E and transmitted to a PC using the WTS-BS-6 Wireless Telemetry Dongle Base Station. Using this solution, Santa was able to gather highly accurate data to determine that their bikes met performance standards through this final testing.

With new technology and a rising need for fast, safe and reliable delivery of all the gifts around the world, it takes a lot of belief, mixed with magic, advanced engineering and precision test and measurement to meet the demand for Christmas presents every year. And Interface proud to be the load cell of choice for Santa’s workshop.

Merry Christmas, Happy Holidays, and Happy New Year to all from everyone at Interface!