Interface provides a range of sensor technologies that are utilized by manufacturers and testing engineers in the agriculture and food production markets. This includes our precision load cells, torque transducers, multi-axis sensors and miniature load cells, along with the popular tension links, load shackles, wireless instrumentation and more. As a complete solutions provider, we have a variety of force measurement products that are designed for modern agricultural testing projects and as components for OEMs. Our Interface expert application engineers can help with standard products as well as design customized solutions for all types of applications using our products that are used for harsh environments, material handling, complex agricultural machines, and extreme weather conditions, engine testing, all ensuring maximum safety and efficiency. The following application notes examples provide an overview of how Interface serves the agriculture sector:

Livestock Weighing Application

Weighing cattle is a critical process in the dairy industry. Farmers need to make sure their livestock are at a healthy weight and maintain their weight. They also want to know the optimal time for breeding based on the weight, meaning it needs to be as accurate as possible. In this use case, Interface provided four SSB Sealed Beam Load Cells. The load cells sit at the bottom of a metal weighing platform that is placed on the inside of the customer’s cattle cage. Once the cow has walked onto the plate, the SSB Sealed Beam Load Cells measure the force pressure applied. With all four connected to a JB104SS Junction Box, which is then connected to the 480 Bidirectional Weight Indicator, combined accurate weight results will be displayed. With this solution, the customer was able to determine accurate weight measurements of their livestock to keep them healthy and determine optimal breeding time.

Silo Grain Dispensing

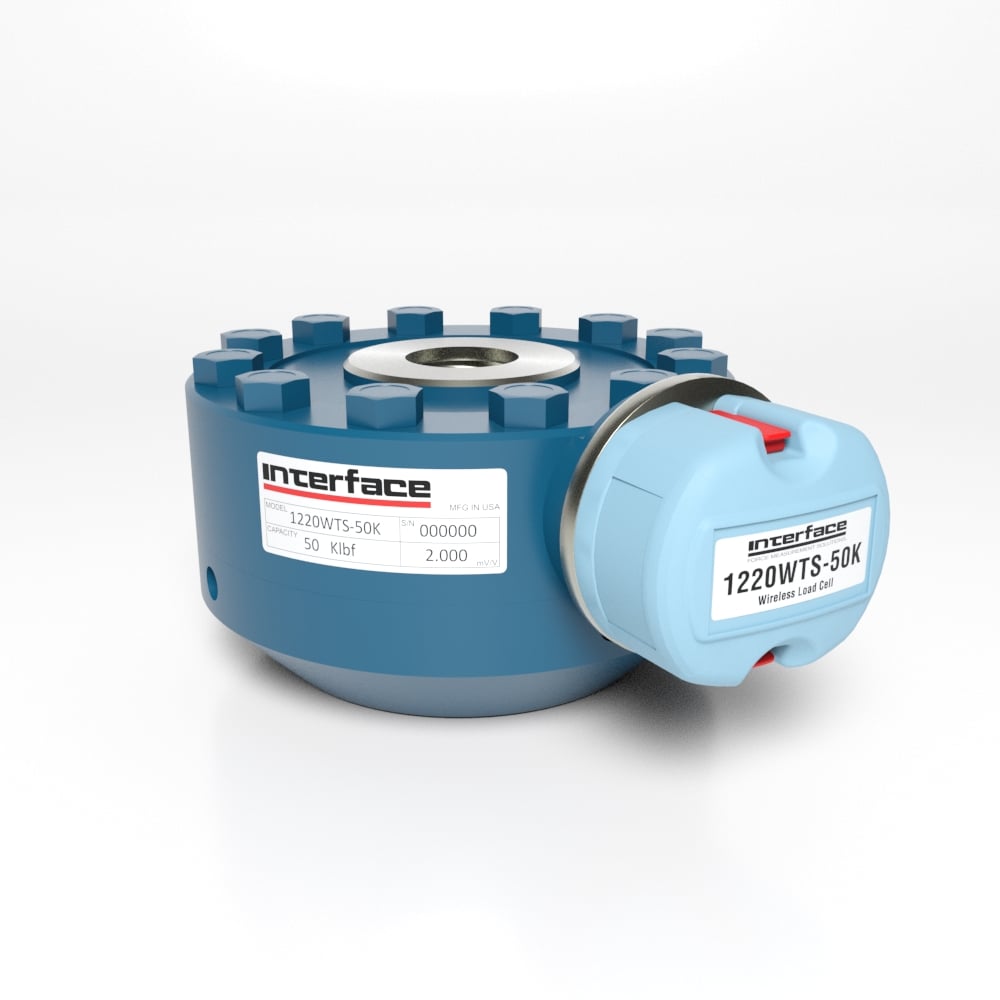

For a silo returning grain into a dispensing container, the customer wanted to measure and record the grain being put in and out of their grain dispensing container. They wanted real-time measurement as it dispenses content into a carrier truck for transportation. The customer also preferred a wireless solution. Interface suggested installing WTS 1200 Standard Precision LowProfile™ Wireless Load Cells at the legs of the grain dispensing container. The 1200 measures the distribution correlation of the grain as it’s inputted and outputted from the container. Results are transmitted and displayed using the WTS-BS-1-HA Handheld Display for multiple transmitters and logged and graphed using the WTS-BS-4 USB Industrial Base Station. Utilizing these products, the customer was able to log and graph the measurement results of the grain content during storage, dispensation and when loaded onto transportation vehicles. This solution eliminated all the guesswork and ensured accuracy in the storage and movement of the material.

Poultry Feeder Monitoring

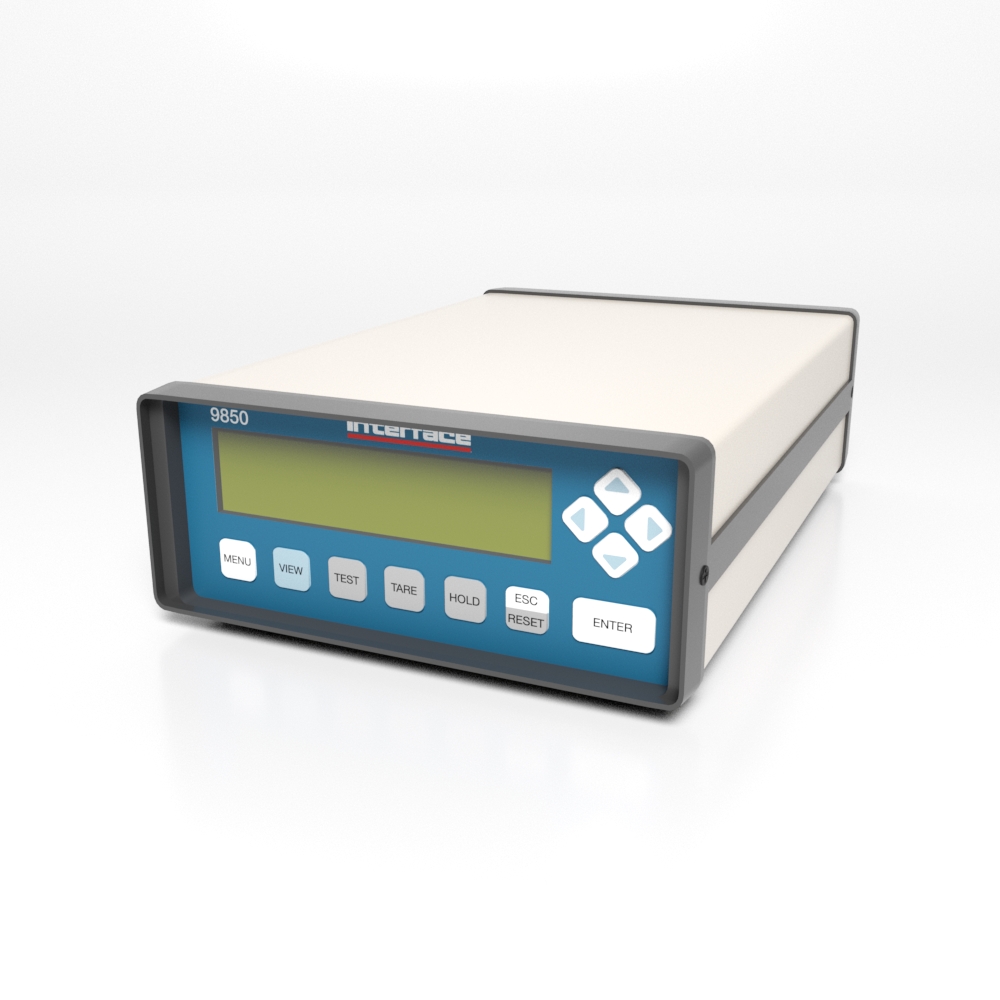

When a customer wanted to monitor the motor that operates their poultry feeders to ensure it gave out an equal distribution of feed per poultry house, Interface’s suggested using the T5 Standard Precision Pedestal Mount Shaft Style Rotary Torque Transducer, with the speed angle option. The transducer attached between a poultry feeder and a motor with Interface’s Couplings. With this solution, torsion measurements can be graphed and logged using the 9850 Torque Transducer and Load Cell Indicator. This allowed the customer to monitor their poultry feeders and confirm that every feeder got the same amount of food distributed to it for safety and efficiency.