Solution

Fuel Pump Optimization – Rotary Torque

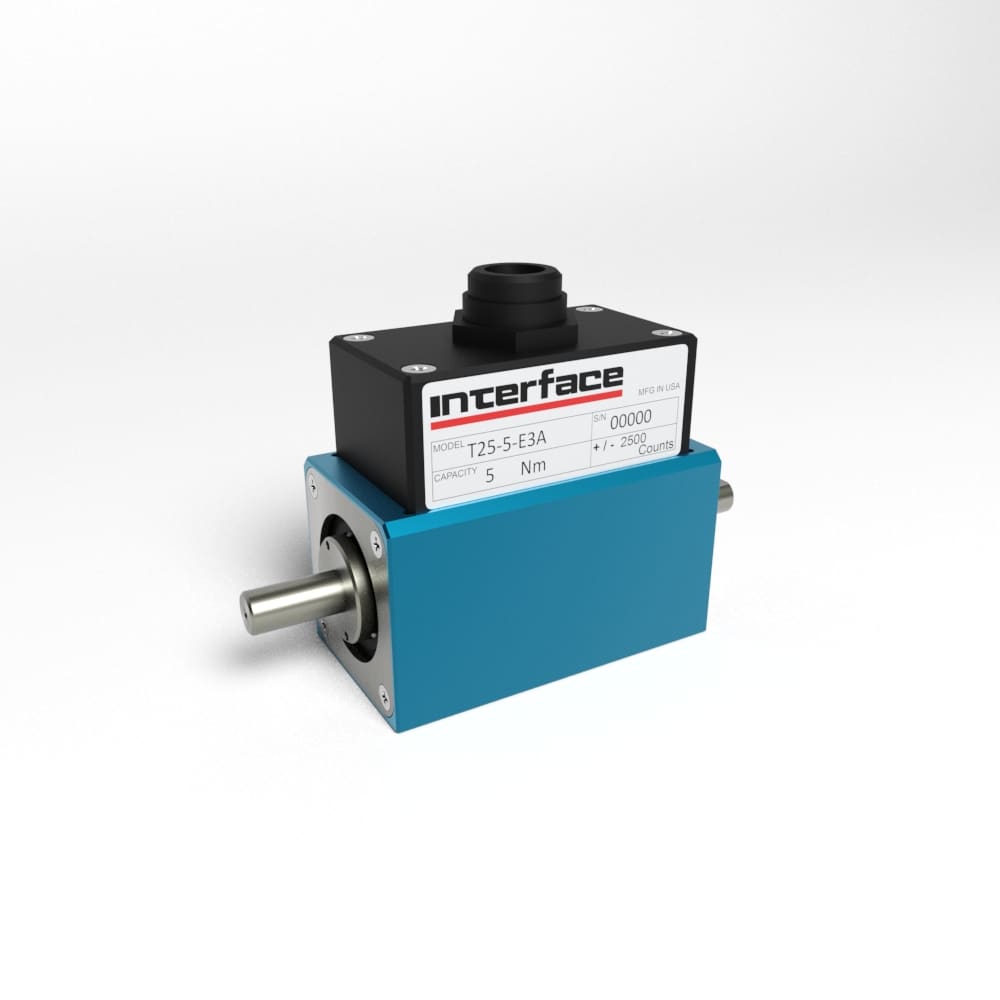

A nationally renowned race team was using a flow bench to measure fuel pump performance. They wanted to determine if they could reduce the power consumption of the pump by further analyzing the precise torque it produced.