Interface Steps in to Support Medical Industry COVID-19 Innovations

The COVID-19 outbreak has hit everyone hard and many industries are rushing to adjust to this new world. One of the industries most impacted by the outbreak has been the medical sector. Hospitals are in a position of running dangerously low on supplies and equipment to treat the influx of patients coming through the doors for vital treatment.

The COVID-19 outbreak has hit everyone hard and many industries are rushing to adjust to this new world. One of the industries most impacted by the outbreak has been the medical sector. Hospitals are in a position of running dangerously low on supplies and equipment to treat the influx of patients coming through the doors for vital treatment.

Fortunately, global innovators, product designers and manufacturers in the medical sector and outside the industry have stepped up to provide solutions critical to the fight against COVID-19. Some of the largest original equipment manufacturers (OEMs) in the world, such as Honeywell Aerospace, 3M, and Ford, have reallocated significant resources within their facilities to help produce medical equipment and PPE like the much needed N95 Masks.

Medical OEMs are also ramping up production on certain technology aimed at preventing, testing, and treating the corona virus. One of the most significant pieces of medical technology needed in this pandemic are ventilators. Prior to the outbreak, analysts predicted a shortage of these devices, which are needed to treat the rising number of patients. OEMs around the world stepped up to mass-produce high-quality ventilators to meet this demand.

The production of ventilators did not just fall upon the shoulders of the OEMs. Thousands of design and test engineers in coordination with manufacturing service providers involved in the ventilator supply chain also leaned in to support the demand. Interface is proud to help participate as part of the supply chain, helping essential OEMs around the world with critical force and torque testing products.

One example related to ventilators came in April of this year when SISU reached out through our representative network to T&M Instruments in Texas. Jace Curtis worked with Interface to urgently provide our T8 General Purpose Shaft Style Rotary Torque Transducers. Jace, who represents the Interface product line, worked with a team of suppliers and testing experts to get the product design through testing quickly. This meant the transducer needed to be in-house within 24-hours. Working with Brian Peters, the product was expedited due to the sensitive nature of this requirement and delivered from our Scottsdale headquarters in the time requested.

SISU is currently designing and manufacturing the AUSTIN P51, a low-cost ventilator to aid hospitals and medical professionals in the current world-wide shortage, and they needed the torque transducers as quickly as possible to help test and verify the ventilator stepper motor.

The challenge with this project was that SISU was targeting the manufacturing of 100,000 ventilators on a very rigorous timeline and they did not have time to program a test to acquire and analyze this data. They needed to quickly set up a test correlating lung pressure to the torque of the stepper motor when the adjacent paddles squeeze the self-inflating bag. Air is then driven through a series of pressure regulators and a HEPA filter that can assist or support the human lungs when compromised.

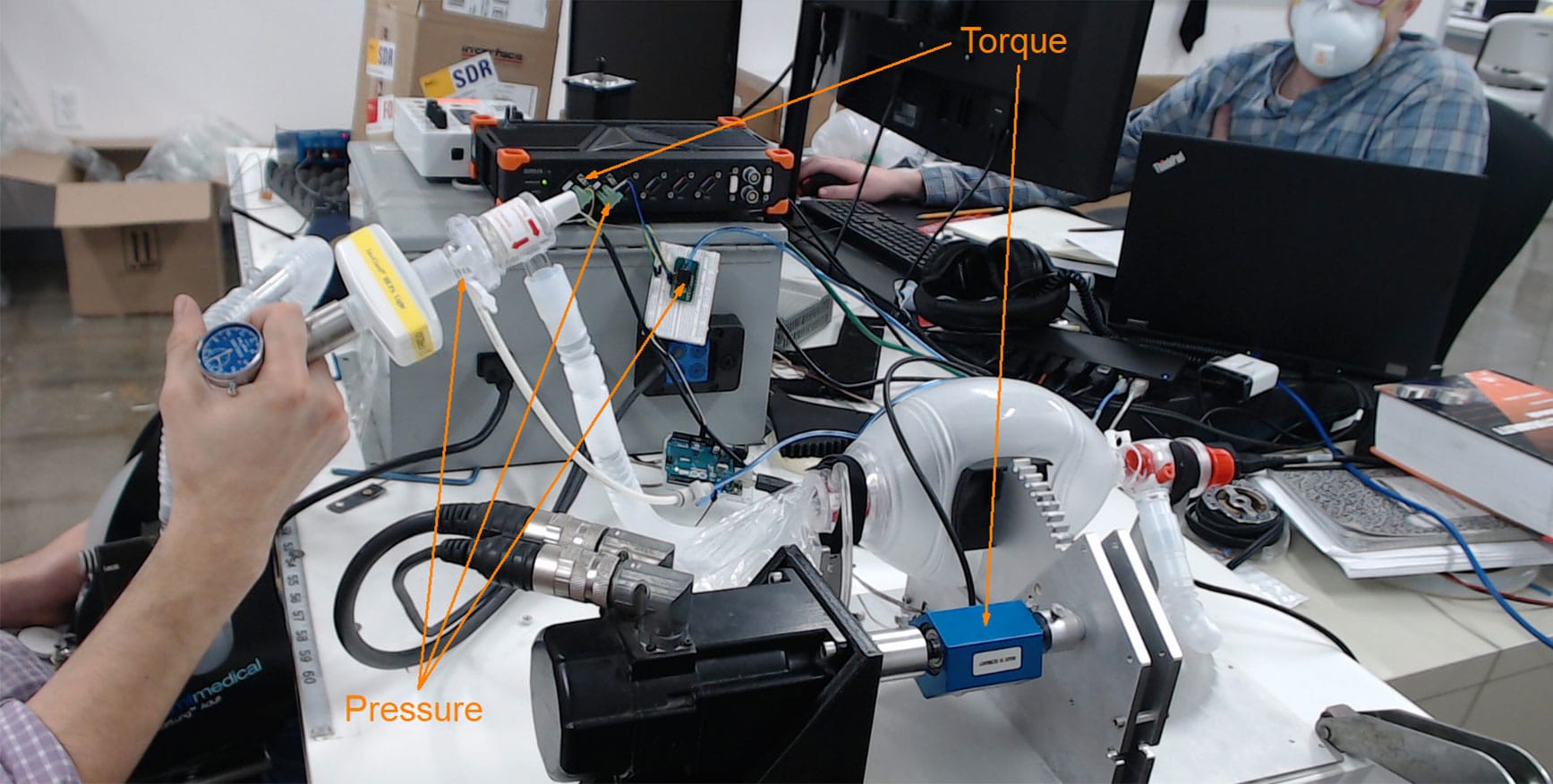

DEWESoft USA, a company that develops and manufactures versatile and easy-to-use data acquisition systems, was charged with the development of this test system. They immediately got to work and were able to deliver a test platform capable of verifying the torque and air pressure within hours.

One of the key pieces of technology in the development of the test system was our torque transducers. The purpose of the torque transducers in the test platform was to analyze the stepper motor and gather data to ensure performance and accuracy. It was critical that the motor performed to specification, and our stainless steel, contactless T8 Torque Transducers were well-equipped to provide DEWESoft® with highly accurate, real-time data.

Additionally, not only was Interface able to overnight the T8 Torque Transducer to DEWESoft on a Saturday morning, but we were able to absorb some of the costs due to the nature of the product need and these unprecedented times. Jace Curtis was also onsite on Saturday to help assist with set-up and testing.

DEWESoft recently put together an application note and video showing the test platform in action. In these pieces, you can see how our torque transducer is used within the testing platform. Included below are links to DEWESoft’s video and application note:

- Video: DEWESoft USA assisting SISU in design & manufacturing ventilators

- Application note: Emergency Ventilator Testing To Aid Hospitals in Coronavirus Crisis

Interface is proud to be an essential business in this time of crisis. It was our duty and honor to support T&M Instruments and DEWESoft in the development of this critical testing platform for life-saving ventilator technology manufactured by SISU. It is our commitment to all our customers. We are here to help.

Contributors: Jace Curtis and Brian Peters