Solution

Chemical Reaction-Mixing

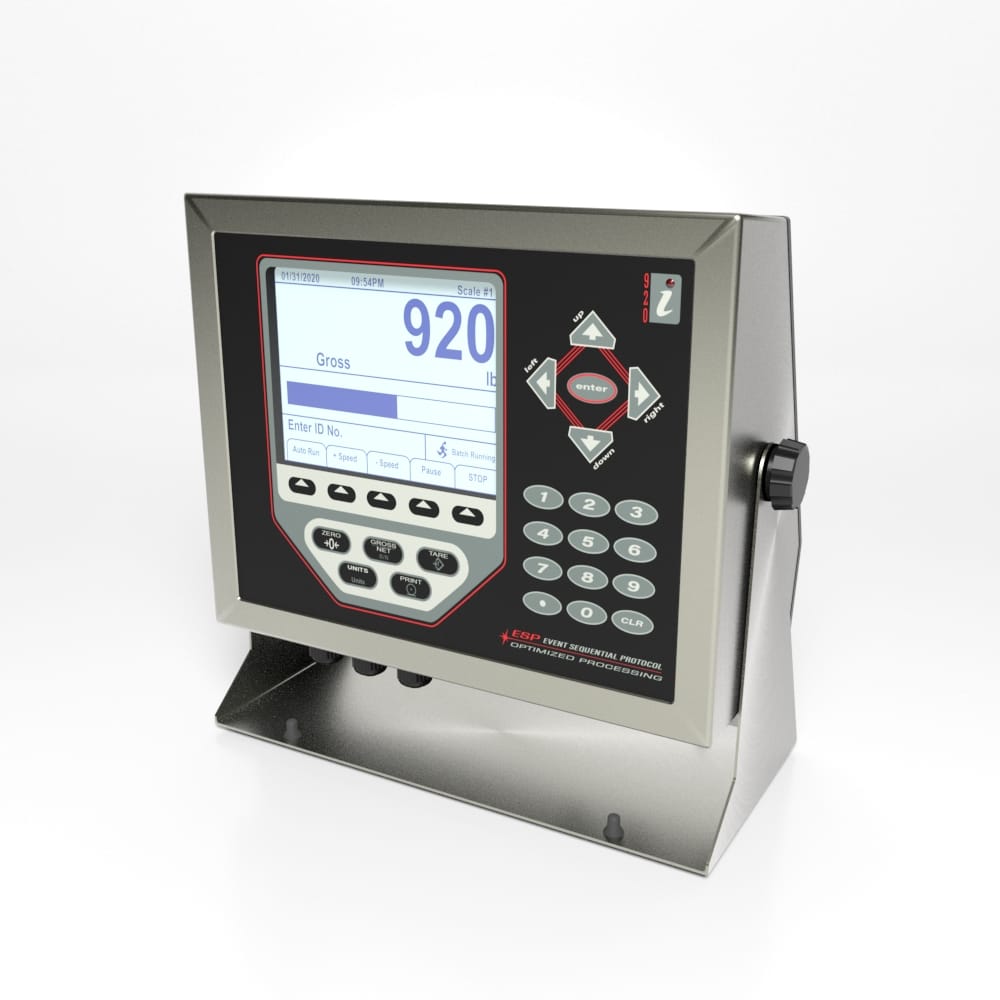

An end product is made by mixing various raw materials together in a

mixing tank. Customer wants to ensure product quality and safety, it’s important that the ingredients are mixed properly without under or overmixing. To do this, the density and viscosity of the mixture must be continuously analyzed during the mixing process.