Solution

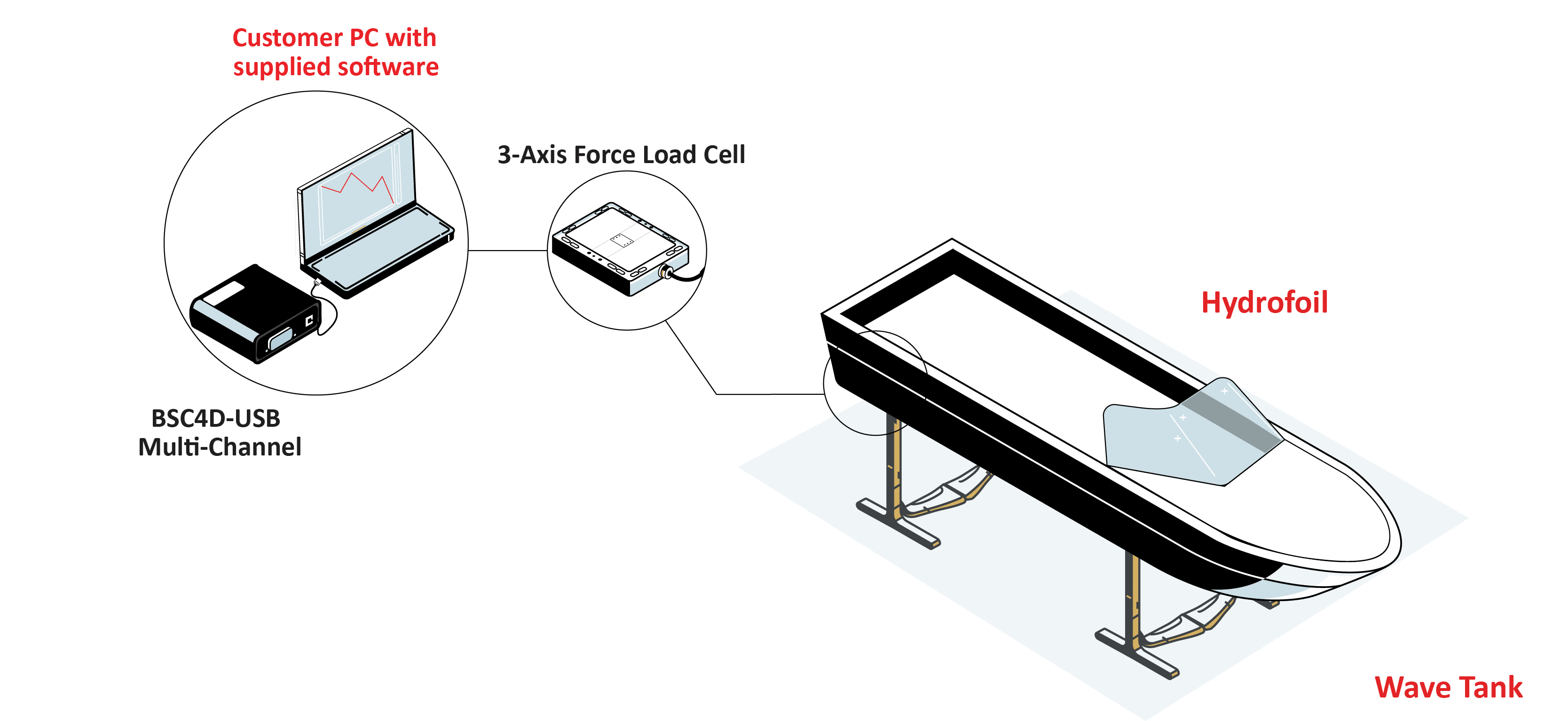

Hydrofoil Testing in Wave Tank

Hydrofoil design is a delicate balance between performance and complexity. Finding the right shape without using overly complex angles to achieve the desired amount of lift is crucial when designing a successful hydrofoil.