Load Cells Built for Stress Testing

Stress testing with load cells is an integral part of research, design, and manufacturing processes for various products and components. It helps to ensure that material, equipment, and final products can withstand the stresses they will be subjected to in regular use.

Stress testing with load cells is an integral part of research, design, and manufacturing processes for various products and components. It helps to ensure that material, equipment, and final products can withstand the stresses they will be subjected to in regular use.

Stress testing with load cells involves applying a known load to a test specimen and measuring the resulting strain. The strain is then used to calculate the stress, which measures the force per unit area.

For destructive stress testing, the test specimen is loaded to failure. The failure load is then used to calculate the ultimate tensile strength (UTS) of the material. In non-destructive testing, the test specimen is loaded to a predetermined stress level and then unloaded. The stress-strain curve is then plotted to determine Young’s modulus and the yield strength of the material.

Selecting the right load cell for any stress testing protocol is important. A detailed review of the sensor’s performance specifications is where to start. Consider the quality of the load cell, along with the materials used to build the testing device and the strain gages.

In designing and building load cells, material composition and build quality play a critical role in the quality, accuracy, and overall lifetime of a load cell. This is especially true when testing involves long, stress-test cycle testing. Interface load cells are designed for optimum fatigue life.

Built for Stress

When looking for a load cell that needs to go the distance over long periods, it’s essential to understand the difference between sensors built for stress and those not. In materials science, the S-N curve is a well-known tool. It is a graphical representation of the number of load cycles required to break a specimen at the range of peak cyclic stress levels. S-N curves for the high-quality materials used in Interface load cells determine the stress level.

Commonly selected load cells used for high-stress level testing are known as fatigue-rated. Fatigue-rated load cells are designed explicitly for component durability and fatigue test machines where highly cyclical loading is present. These quality load cells resist extraneous bending and side-loading forces.

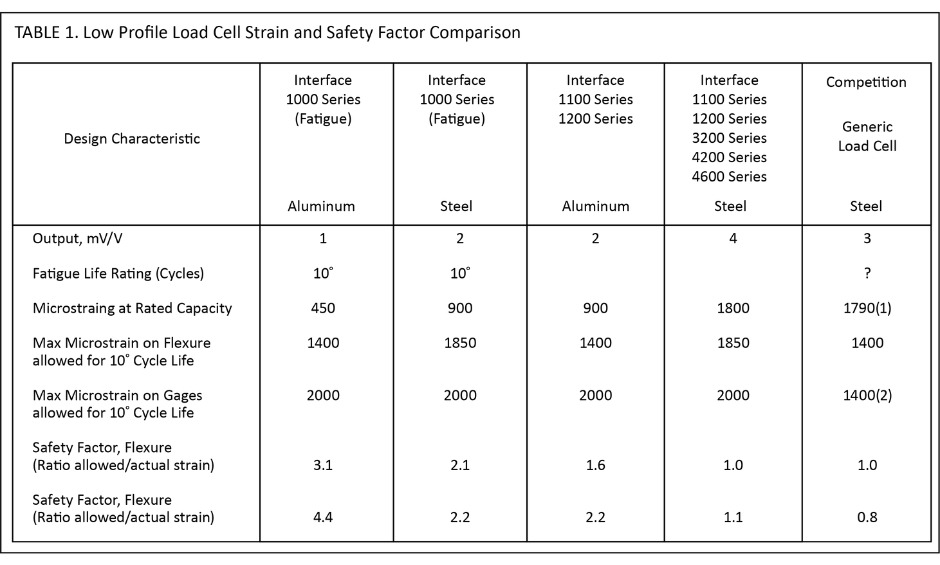

The table below outlines a load cell strain and safety factor comparison chart, which shows how Interface load cells, including our 1000 Fatigue-Rated Universal LowProfile® Load Cell and 1000 High Capacity Fatigue-Rated Universal LowProfile® Load Cell stack up against generic competitive load cells.

This table compares actual strain levels in Interface LowProfile Load Cells versus generic load cells. The safety factors are a means of visualizing the merit of the various designs. The value of fatigue-rated load cells for fatigue applications is evident from the safety factor data. It is also apparent that Interface load cells with 4 mV/V output have lower stress levels and, therefore, more fatigue resistance than other cells, even though their output is only 3 mV/V or less.

Lower Stress by User Limits

Note that the tests in the safety factor comparison are based on fully reversed load cycles. This type of loading cycle is considerably more stringent than unidirectional loading, which is the more common application of load cells. Suppose a fatigue load cell is repeatedly loaded in only one direction. In that case, the Goodman Law predicts that it can be loaded to about 133% of the bidirectional fatigue-rated capacity with no degradation of its fatigue rating. Conversely, unidirectional loading to a fatigue cell’s rated capacity is much less stressful on the cell than bidirectional. It can be expected to yield a fatigue life well beyond the number of cycles that could be reasonably and economically applied in a verification test program. For additional information on this topic, please refer to Interface’s Load Cell Field Guide under Fatigue Theory.

ADDITIONAL RESOURCES

Fatigue Testing with Interface Load Cells

Force Measurement is Fundamental in Material Testing