Load Cells

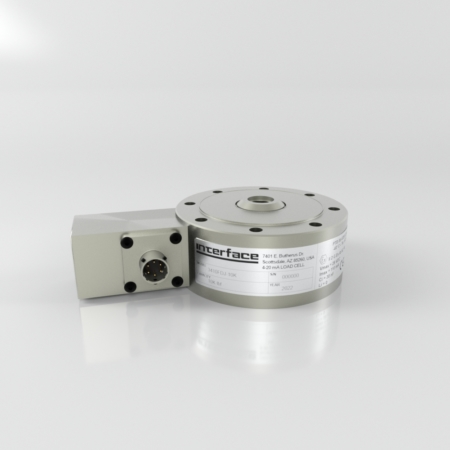

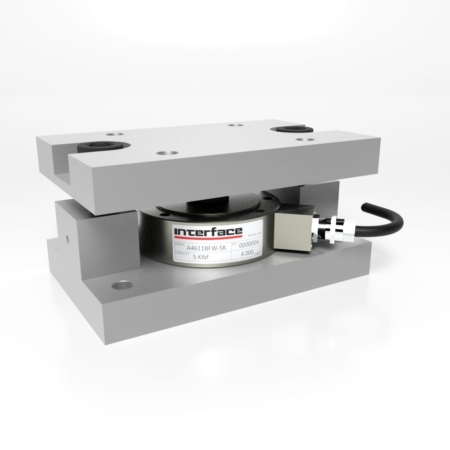

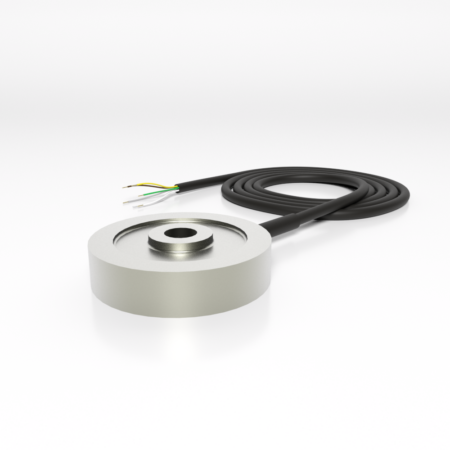

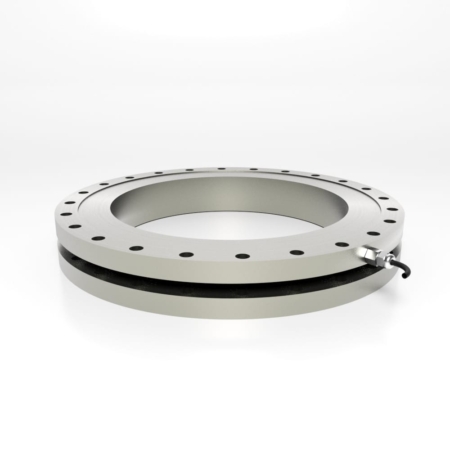

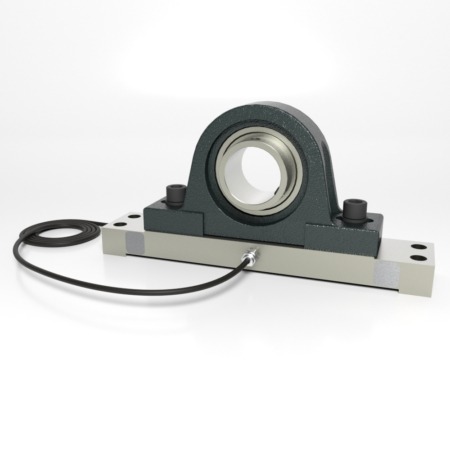

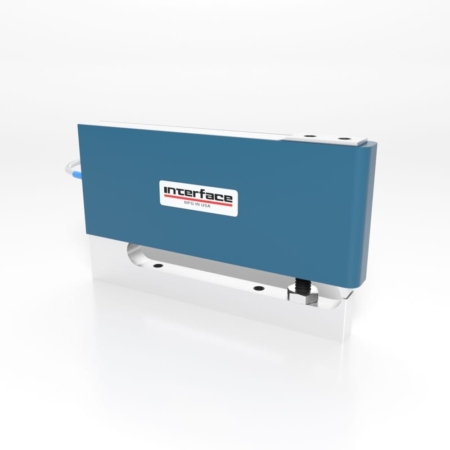

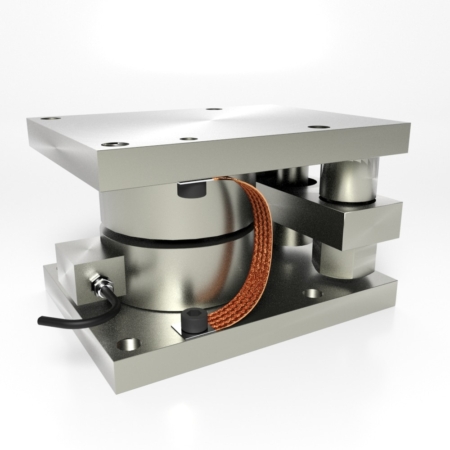

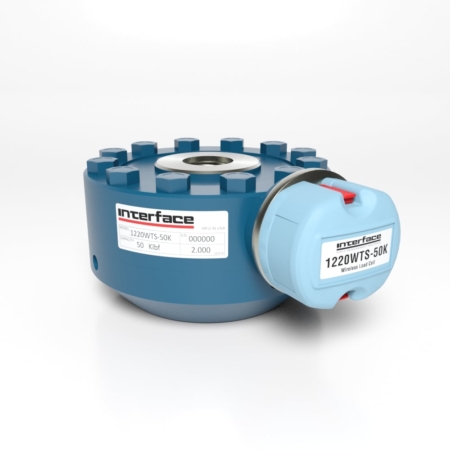

Here at Interface we manufacture more than 60 different types of load cells and interface Mini’s™. We have capacities ranging from 1 lbf / 500 gf to 2 million lbf / 9,000 kN. Our facility produces them in several shapes and sizes. Models similar to pancake load cell and donut load cell including our LowProfile® load cell and thru-hole load cell.

Additionally, our canister, rod end, downhole, column, coil tubing, load buttons, and load washers all use our proprietary alloy strain gages. This helps us produce the most accurate and reliable data possible. Therefore, with the wide variety of load cell specs we have in stock, most customers are able to use an off-the-shelf application. However, our engineers can also work with you to design a custom load cell to fit your exact needs. Contact us so that we can help you find a solution that fits your needs.

Use the NEW Interface Load Cell Selection Guide to assist you in choosing the load cell best suited for your application.