Technical Library

Our extensive technical library has just about everything you need from cable length effects to glossaries to system calibrations and load cell troubleshooting. If you don’t find what you need, just hit the “contact us” button!

Our extensive technical library has just about everything you need from cable length effects to glossaries to system calibrations and load cell troubleshooting. If you don’t find what you need, just hit the “contact us” button!

This document defines the terminology and performance parameters pertaining to engineering specifications of load cell products.

The objective of this terminology standard is to promote effective communication of specifications and to constitute a reference for uniformity.

The definitions herein are generally compatible with common understanding in the load cell community and are an expansion of those found in Load Cell Terminology and Test Procedure Recommendations, Third Edition, 1985, Scale Manufacturers Association, and in OIML International Recommendation R60, 1991 Edition.

This document includes modifications to the definitions in the above referenced standards to correct some of their inconsistencies and inadequacies.

All abbreviations are case-specific, are not to be pluralized, and do not use trailing periods.

| ampere combined error degree Celsius degree Fahrenheit degree Kelvin foot foot-pound 1 full scale gram gram force hertz inch inch-pound 2 kilogram kilogram force kiloohm kilonewton kilonewton-meter kilopound-foot kilopound-inch kilopound (kip) kilopound force megaohm |

A CE °C °F °K ft ft-lb FS g gf Hz in in-lb kg kgf Kohm kN kNm Klbf-ft Klbf-in K Klbf Mohm |

meganewton meter milliampere millimeter millivolt millivolt/volt minimum dead load newton newton-meter ohm ounce-inch pound pound-foot pound-inch pound force pound per square inch rated output static error band ton, metric volt volt direct current volt alternating current watt |

MN m mA mm mV mV/V MDL N Nm ohm oz-in lb lb-ft lb-in lbf psi RO SEB t V VDC VAC W |

|

| Note 1 – pound-foot is preferred Note 2 – pound-inch is preferred |

||||

LowProfile™ Load Cells

The Best Just Got Better!

Performance Improvement with No Price Increase

Click the images on the left to view them enlarged.

Scroll down to the bottom of this page for a PDF download.

Introducing Interface’s Enhanced

LowProfile™ Load Cell

Interface Inc. pioneered the first Low Profile™ load cell in 1969 and is the largest producer of them in the world. We guarantee that our load cells will out perform our competitors…PERIOD.

Interface Blue…

Setting the Standard in Force Measurement

Interface is Raising the Bar In High Performance Force Measurement

A 20% improvement in performance based on over 2 years of extensive engineering development

UNPARALLELED RELIABILITY

Performance Parameters That Set Us Apart From Our Competitors

World Leading Performance Begins at the Core of Our Product

Proprietary Strain Gages

Temperature Effects

Calibration

Interface Moment Compensation

Options available for a variety of applications

Interface LowProfile™Load Cells

We Recalibrate ALL Manufacturers’ Load Cells

For high accuracy force measurement the effects of the cable on the measurement must be considered. For constant voltage excitation there are two effects of significance.

These are:

If the load cell is sold with a cable of any length, the sensitivity is determined with the installed cable in calibration and this is not a problem. For load cells with connectors, or if the customer adds cable himself, there will be a loss of sensitivity of approximately 0.37% per 10 feet of 28 gage cable and 0.09% per 10 feet of 22 gage cable. This error can be eliminated if a six wire cable is run to the end of the load cell cable or connector and used in conjunction with an indicator that has sense lead capability.

Since cable resistance is a function of temperature, the cable response to temperature change affects the thermal span characteristics of the load cell/cable system. For 6-wire systems this effect is eliminated. For 4-wire cables the effect is compensated for in the standard cable lengths offered with the load cells if the load cell and cable are at the same temperature at the same time. For non-standard cable lengths, there will be an effect on thermal span performance. The effect of adding 10 feet of 28 gage cable is to cause a decrease in sensitivity with temperature equal to 0.0008%/°F (an amount equal to the standard Interface specification). For an added 10 feet of 22 gage cable the effect is to decrease sensitivity by 0.0002%/°F (one-fourth Interface spec). In many cases a customer can tolerate the degraded performance since our standard specification is extremely tight. However, for long cable runs or high accuracy applications, this can be a significant factor. In such cases, the best approach to the problem is to run six wires to the end of the standard cable length and sense the excitation voltage at that point. This eliminates the problem.

Figure 33. Simple column cell

All Interface, Inc. products are designed around either the bending beam, the shear beam, or the pipe column. In order to understand the reasons behind this decision, we need to understand the design of the plain column cell, the other major type of load cell.

The cross-section view in Figure 33 shows the components of the simple column cell. The “flexure” is the heavy column (A) running up the center of the cell, with massive blocks at the top and bottom and a thin, usually square, column in the center. This column, plus the heavy outer shell and the diaphragms (B) are the basic support elements for the measurement flexure, the column (A) which runs from S1 to S2 .

The column stress between S1 and S2 is about the same anywhere along its length, so the main gages (C1 and C2) are placed in the center, at Sg. Compensation for the nonlinearity of the column design is accomplished by the semiconductor gage (F).

Loads are applied by the customer’s fixtures which can be screwed into the threaded holes at the top and bottom ends of the column.

The “doghouse” on the side of the casing contains the bridge compensating resistors (D) which are wired (E) to the gages.

At first glance, this might seem to be an uncomplicated design. The physical parts themselves are relatively simple to produce. However, several characteristics seriously restrict its usability.

By contrast, the LowProfile cell compares dramatically better in all respects to the simple column cell.

Force and torque transducers must be calibrated in a laboratory in order to be useful in their intended application. Applications of transducers range from basic process measurements to critical calibration of other transducers or equipment. The laboratory calibration consists of loading the transducer with known masses and lever arms, or using a comparison method where load is generated by hydraulic or pneumatic means and the transducer under test is compared to a reference transducer. In either method, the cost of calibration equipment rises rapidly with increasing capacity.

Many calibration laboratories have the means to calibrate force up to about 10,000 lbf and torque up to about 20,000 lb-in, but capability for higher ranges is scarce. In fact, there are a very limited number of laboratories in the United States that have the capability for force over 200,000 lbf and torque over 100,000 lb-in.

There has been a practice in the past by some manufacturers of transducers to calibrate a high capacity transducer at partial capacity, leaving the owner to go on hoping and guessing for the sensitivity of the upper end of the capacity. This gives rise to the concept of extrapolating the partial capacity calibration to full capacity, thereby providing the possibility for an increase in confidence in the extended range.

Strain gage transducers are basically linear. That is, the output follows the input at a near constant ratio. The nonlinearity is routinely measured and typically is in range of ± 0.10%FS or less. This provides for the ability to interpolate values between calibration points with near zero error. However, the same is not true for extrapolation, which is really estimating values that are beyond the observable range. Conventional wisdom has it, and logically so, that extrapolation is not a valid method of calibration. Extrapolating is similar to forecasting, and that idea helps one realize the liability of it.

The various methods of extrapolation are not all equal. The purpose of this paper is to explore a method that has reasonable validity when economic considerations do not permit a full capacity calibration.

The use of load cells and a data logging system are a necessity in the majority of situations where materials, parts, or assemblies are fatigue tested to destruction. This is true because an accurate record of the forces at every moment of the tests is the only way that an engineer can analyze the stresses which occurred in the moments just prior to the ultimate failure. No one can accurately predict exactly when the failure will occur, nor which part of an assembly will be the weakest link which eventually fails.

When designing a test protocol, serious thought should be given to the possibility that some of the parameters of the test will need to be changed as the result of information learned in the early test cycles. It may be that the test frequencies, force levels, location or angle of force application, or phasing of test waves will need to be changed. It is therefore prudent to start out with equipment which can accommodate an increase, a decrease, or other change without a major redesign of fixtures or a major expenditure to convert or replace high cost test equipment.

“Fatigue Rated” is an exact Interface specification which defines a special class of load cell design and construction.

Not all manufacturers adhere strictly to the stringent discipline necessary to produce true fatigue rated load cells on a consistent basis. By contrast, the history of Interface Low Profile cells shows a zero return rate due to fatigue failure, for fatigue-rated cells used within ratings.

Although Interface does not recommend it, there are times when circumstances force a user to apply a large number of test cycles on a non-fatigue-rated cell. The following guidelines may assist the user in deciding how long to carry on such a test before installing the properly sized fatigue-rated cell.

If this were the only failure mode, any Interface steel or stainless steel cell could be used as a fatigue cell, if operated below 500/0 of its rated capacity. However, other minor failure modes would take over, because the load cell would be missing the “hand crafted” steps of the manufacturing process.

Many test protocols require a fixed load plus a dynamic load to be applied to a test sample simultaneously. An Interface fatigue-rated load cell is well suited to this type of application. However, there are limitations which should be applied to the loadings, to insure that the cell will be operating in its linear range and to avoid overloading the load cell or reducing its fatigue life.

The Goodman Curve shown in Figure 50 is a useful nomograph (visual calculating graph) for easily figuring combined loading limits for fatigue-rated cells. Notice that the dynamic loading limit by itself is 100% of the fatigue rating, and the static loading limit by itself is 2000/0 of the fatigue rating. In between these two end points, the limit is the diagonal straight line which connects the end points.

The Goodman Curve applies only to fatigue-rated cells. Using it to calculate combined loadings on a standard load cell could result in damage to the cell.

In the example shown on the graph the dashed line indicates a situation where we want to apply a fixed load of 70%, and we want to know how much dynamic load we can apply simultaneously. By taking a straight horizontal line at the “70% Static Load” level across to the limit line and then projecting downward from that intersection, we find that the intersection on the dynamic scale at “65% of Rated Fatigue Capacity.” This means that, on a 1000 lbf rated fatigue cell, we could apply a fixed load of 700 lbf combined with a dynamic load of 650 lbf peak in both modes.

Checking the graph, note that if we needed to apply a fixed load of 160%, we could still apply a dynamic load of 20% for a total load which varies between 140% (lower peak) and 180% (upper peak). This would mean that the cell would be operating outside the limit of the normal factory calibration on fatigue cells of 100%. If the utmost accuracy is desired, it might be advisable to have a static calibration done on the cell up to 200%, which can be done on a fatigue-rated cell by special order.

Interface has specialized in fatigue-rated load cells and their applications since its founding in 1968. Fatigue rating is a distinct specification which guarantees the customer a load cell which has a service life of 100 million fully reversed loading cycles at full rated capacity.

The very first products at Interface were fatigue-rated load cells, and over the years a history has been built up by thousands of cells in use all over the world. Many have been supplied to major manufacturers of materials test machines and to major aerospace manufacturers, for use in long term structural fatigue test programs on aircraft, space, and automotive equipment. No fatigue failure of any fatigue-rated Interface load cell, used within its ratings, has ever been reported.

It is well known that metals will fail in a statically loaded situation if the yield strength is exceeded. In as much as load cells are structural members which are stressed in the course of their normal use, they are commonly given ultimate overload ratings in an effort to characterize the magnitude of static load they will withstand without failing structurally.

However, all metal structures, including load cells, are also subject to failure as a result of repetitive loadings which are much lower than the ultimate overload rating. This phenomenon is known as a fatigue failure, and it is due to the fact that the stress which a metal can withstand under cyclic loading usually becomes less and less as the number of cyclic loadings is increased.

The cause of this apparent anomaly can be explained by noting that metals are typically not perfectly homogeneous solids. They are composed of crystals, and at locations called grain boundaries, along slip planes or in a region of a microscopic defect there can be minute strains under load which do not completely reverse during unload, leaving the material with a slight plastic deformation at the end of each complete cycle. This effect is highly dependent on the magnitude of the load and the number of cycles.

It is generally acknowledged that a structural fatigue failure develops in three stages:

Accurate prediction of fatigue life of any structure is not a reality. Well controlled tests on the most simple configurations of test specimens result in a wide scatter band of results. With complex structures typical of a load cell, analysis is even more complex. Theoretical analysis can produce approximations, however, which can be useful in estimating the margin of safety at which a particular load cell design is operating.

In materials science, the S-N curve is a well known tool. It is a graphical representation of the number of load cycles required to break a specimen, at a range of peak cyclic stress levels. S-N curves for the high quality materials used in Interface load cells have been experimentally determined, and are shown in Figure 1 for stainless steel and alloy steel, and in Figure 2 for aluminum alloy.

Thus, if the stress level is known, the fatigue life can be approximately known. However, there are factors which make fatigue life difficult to characterize.

Components Subject to Failure

There are two metal components in a load cell that must be considered in fatigue analysis, the flexure (spring element) and the strain gage (sensor).

The relative propensity to first encounter flexure or strain gage fatigue failure depends upon the design of the transducer.

Flexures

There are several metals used for flexures in Interface load cells including aircraft quality alloy steel, stainless steel, and high strength fatigue-resistant aluminum alloy. S-N curves for these three materials are presented in Figure 1 and Figure 2.

Stress is normally expressed in units of psi (pounds per square inch), but for convenience we use units of Ksi which are equal to 1000 psi. Shear stress is on the vertical axis, corresponding to the state of stress in Low Profile load cells. Readers with some materials science familiarity will recognize that classical fatigue strength for these materials is higher than indicated in the figures. This is because classical data is for bending or direct stress, whereas Interface fatigue-rated cells operate in shear mode. This analysis therefore appropriately uses the required factor for shear, avoiding a falsely optimistic result.

Note that the shear S-N curve for steel becomes essentially flat at about 55 KSI. This is a characteristic of steel. The stress level at the flat portion of the curve is called the endurance limit. If operated below this limit, theoretically the material will endure an infinite number of load cycles. Nonferrous metals do not generally exhibit an endurance limit, their curves continuing on with a small slope.

Gages

Interface strain gages are specially made of fatigue-resistant nickel-chromium alloy. Strain gage fatigue characteristics are most conveniently viewed in terms of strain rather than stress. Figure 3 shows a Strain-N curve for Interface strain gage material. Strain is a dimensionless quantity of normally very small magnitude. The microstrain unit is simply 106 strain units and is used for convenience. Stress and strain for any particular material are related by a constant which is the modulus of elasticity (30X106 for steel and 10X106 for aluminum), allowing convenient comparison of S-N curves and Strain-N curves.

The curves in Figures 1, 2, and 3 are for fully reversed load cycles, meaning that for 2000 microstrain as an example, a cycle starts at zero load and consists of one load to (+2000), one load to (-2000), with a return to zero.

Comparison of Loading Levels

Superimposed on the curves are operating levels of Interface Low Profile load cells by model series. This provides a convenient visualization of the fact that all of these load cells are designed to have very long, if not infinite, theoretical fatigue lives. Remember that in actual practice things are not necessarily so ideal. Therefore, in order to establish the correlation between theoretical and realizable fatigue life, actual test results are desirable.

Test Protocol

Interface conducted Design Verification Tests to substantiate the theoretical life predictions by means of actual load tests of the product. Obviously, building up millions of load cycles on a high capacity load cell is not a trivial task. Many hours of costly machine time are required. Tests were conducted on three representative Interface Low Profile load cells: (1) an aluminum cell of 5,500 lbf capacity, (2) a steel cell of 11,000 lbf capacity, and (3) a steel cell of 22,000 lbf capacity.

Loading to 130% of rating was selected as an acceleration factor, to bring down the test time to a realizable length, since 100 million cycles at 1 hertz and 100% loading would consume 3 years and 2 months of testing, 24 hours per day. Based on the slopes of the S-N curves, a cycle acceleration factor of at least 10 can be achieved with 130% loading, thus ensuring that the more stringent test at 107 cycles will prove a fatigue life of 108 cycles at 100% loading.

Test Results

Analysis of the test data showed that there were no indications of fatigue failure nor degradation of load cell performance outside specified limits, for the critical load cell parameters of output, zero balance, nonlinearity, hysteresis, and creep, during or after completion of the Verification Test program.

Lower Stress by Design

Interface load cells are designed for optimum fatigue life. Other load cells are not necessarily equivalent. Table 1 below is a comparison of actual strain levels in Low Profile™ and typical competitive load cells. The safety factors are a means of visualizing the design merit of the various designs. The value of fatigue rated load cells for fatigue applications is evident from the safety factor data. It is also apparent that Interface load cells with 4 mV/V output have lower stress levels and, therefore, more fatigue resistance than competitors’ cells, even though their output is only 3 mV/V or less.

Lower Stress by User Limits

Note that the tests and S-N curves are based on fully reversed load cycles. This type of loading cycle is considerably more stringent than unidirectional loading, which is the more common application of load cells. If a fatigue load cell is repeatedly loaded in only one direction, the Goodman Law predicts that it can be loaded to about 133% of the bidirectional fatigue-rated capacity with no degradation of its fatigue rating. Conversely, unidirectional loading to a fatigue cell’s rated capacity is much less stressful on the cell than bidirectional loading and can be expected to yield a fatigue life well beyond the number of cycles which could be reasonably and economically applied in a verification test program.

Excitation Voltage

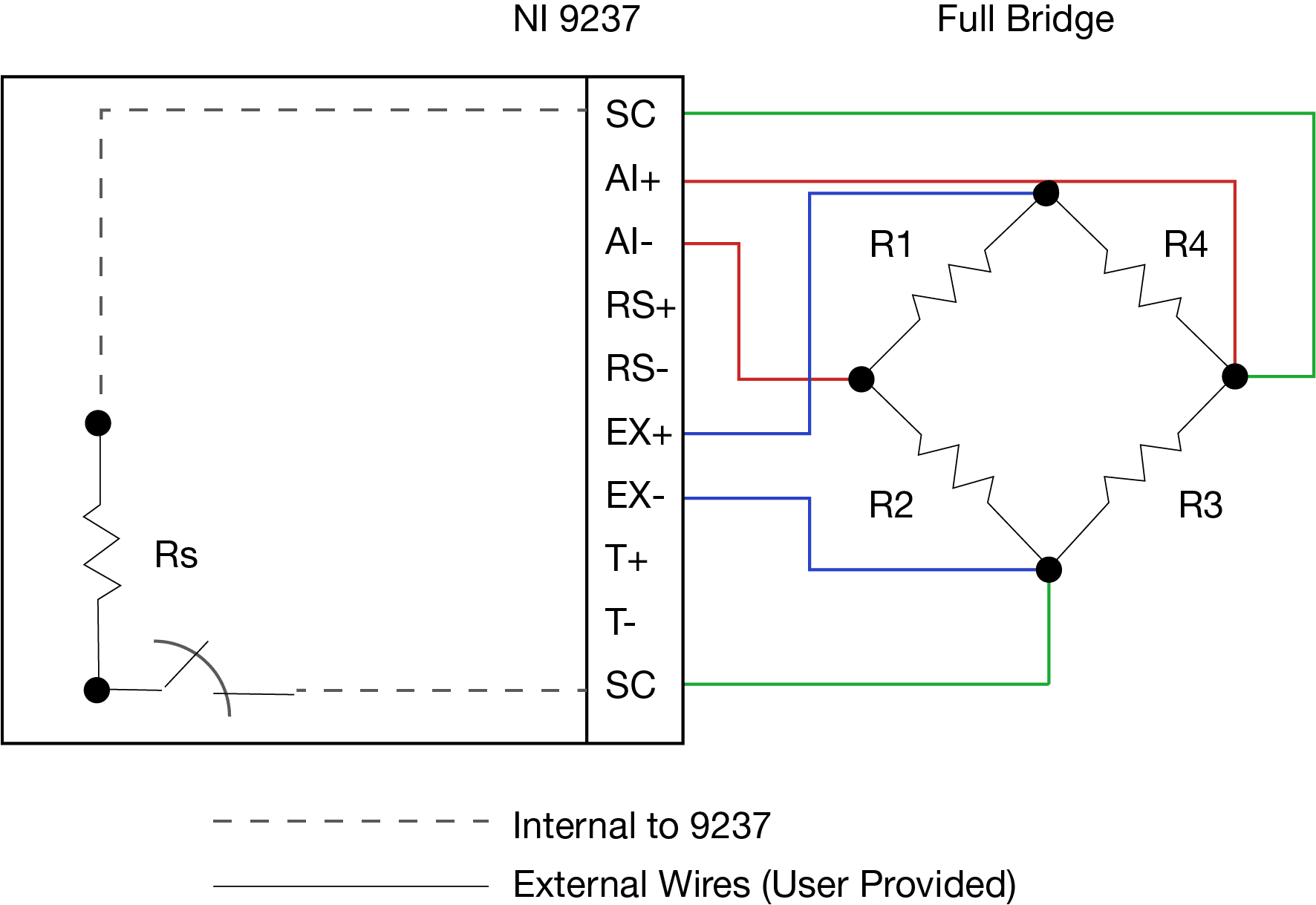

Interface load cells all contain a full bridge circuit, which is shown in simplified form in Figure 1. Each leg is usually 350 ohms, except for the model series 1500 and 1923 which have 700 ohm legs.

…

Print or Download The Entire Document

Copyright 1998–2009, Interface Inc. All rights reserved.

Interface, Inc. makes no warranty, either expressed or implied, including, but not limited to, any implied warranties of merchantability or fitness for a particular purpose, regarding these materials, and makes such materials available solely on an “as-is” basis.

In no event shall Interface, Inc. be liable to anyone for special, collateral, incidental, or consequential damages in connection with or arising out of use of these materials.

For convenience, terms which are defined in this standard are printed in UPPER CASE when used in the definition of another term.

– The temperature of the medium surrounding the LOAD CELL.

– A load applied along the PRIMARY AXIS.

– The change in ZERO BALANCE due to a change in ambient barometric pressure. Normally expressed in units of %RO/atm.

– The comparison of LOAD CELL OUTPUT against standard test loads.

– The maximum AXIAL LOAD a LOAD CELL is designed to measure within its specifications.

– The maximum deviation of the CALIBRATION curve from the straight line drawn between MINIMUM LOAD OUTPUT and MAXIMUM LOAD OUTPUT, normally expressed in units of %FS. Both ascending and descending curves are considered.

– The change in LOAD CELL SIGNAL occurring with time while under load and with all environmental conditions and other variables remaining constant. Normally expressed in units of % of applied load over a specified time interval. It is common for characterization to be measured with a constant load at or near CAPACITY.

– The change in LOAD CELL SIGNAL occurring with time immediately after removal of a load which had been applied for a specified time interval, environmental conditions and other variables remaining constant during the loaded and unloaded intervals. Normally expressed in units of % of applied load over a specified time interval. Normally the applied interval and the recovery interval are equal. It is common for characterization to be measured with a constant load at or near CAPACITY.

– The difference between LOAD CELL SIGNAL immediately after removal of a load which had been applied for a specified time interval, environmental conditions and other variables remaining constant during the loaded interval, and the SIGNAL before application of the load. Normally expressed in units of % of applied load over a specified time interval. It is common for characterization to be measured with a constant load at or near CAPACITY.

– The displacement of the point of AXIAL LOAD application in the PRIMARY AXIS between the MDL and MDL+CAPACITY load conditions.

– Any load applied parallel to but not concentric with the PRIMARY AXIS.

– The OUTPUT corresponding to MAXIMUM LOAD in any specific test or application.

– The algebraic difference between OUTPUT at a given load descending from MAXIMUM LOAD and OUTPUT at the same load ascending from MINIMUM LOAD. Normally expressed in units of %FS. It is common for characterization to be measured at 40-60% FS.þ

– The resistance of the LOAD CELL circuit measured at the excitation terminals with no load applied and with the output terminals open-circuited.

– The DC resistance measured between the bridge circuit and the case. Normally measured at 50 VDC.

– A device which produces an OUTPUT proportional to an applied force load.

– The maximum AXIAL LOAD which can be applied without producing a permanent shift in performance characteristics beyond those specified. Normally expressed in units of % CAPACITY.

– The highest load in a specific test or application, which may be any load up to and including CAPACITY +MINIMUM LOAD, but may not exceed CAPACITY significantly.

– The maximum AXIAL LOAD which can be applied without producing a structural failure. Normally expressed in units of % CAPACITY.

– The maximum moment with respect to the PRIMARY AXIS which can be applied without producing a permanent shift in performance characteristics beyond those specified.

– The maximum torque which can be applied concentric with the primary axis without producing a permanent shift in performance characteristics beyond those specified.

– The maximum SIDE LOAD which can be applied without producing a permanent shift in performance characteristics beyond those specified.

– The difference between MAXIMUM LOAD and MINIMUM LOAD in a specific test or application. It may not exceed CAPACITY.

– The smallest load for which specified performance will be met. It is normally equal to or near NO LOAD in single mode applications and is of necessity equal to NO LOAD in double mode applications.

– The lowest load in a specific test or application, differing from NO LOAD by the weight of fixtures and load receptors which are attached plus any intentional pre-load which is applied.

– The direction of load. Tension and Compression are each one mode.

– The frequency of free oscillations under conditions of NO LOAD.

– The condition of the LOAD CELL when in its normal physical orientation, with no force input applied, and with no fixtures or load receptors attached.

– The algebraic difference between OUTPUT at a specific load and the corresponding point on the straight line drawn between MINIMUM LOAD and MAXIMUM LOAD. Normally expressed in units of %FS. It is common for characterization to be measured at 40-60 %FS.

– The maximum difference between OUTPUT readings for repeated loadings under identical loading and environmental conditions. Normally expressed in units of %RO.

– The algebraic difference between the SIGNAL at applied load and the SIGNAL at MINIMUM LOAD.

– The resistance of the LOAD CELL circuit measured at the SIGNAL terminals with no load applied and with the excitation terminals open-circuited.

– The axis along which the LOAD CELL is designed to be loaded.

– The OUTPUT corresponding to CAPACITY, equal to the algebraic difference between the SIGNAL at (MINIMUM LOAD + CAPACITY) and the SIGNAL at MINIMUM LOAD.

– The smallest change in load which produces a detectable change in the SIGNAL.

– Electrical simulation of OUTPUT by connection of shunt resistors of known values at appropriate points in the circuitry.

– Any load at the point of AXIAL LOAD application acting at 90° to the PRIMARY AXIS.

– The absolute level of the measurable quantity into which a force input is converted.

– Another name for RATED OUTPUT.

– The band of maximum deviations of the ascending and descending calibration points from a best fit line through zero OUTPUT. It includes the effects of NONLINEARITY, HYSTERESIS, and non-return to MINIMUM LOAD. Normally expressed in units of %FS.

– A computed value for OUTPUT at CAPACITY derived from a line best fit to the actual ascending and descending calibration points and through zero OUTPUT.

– The algebraic difference between the RATED OUTPUT in tension and the average of the absolute values of RATED OUTPUT in tension and RATED OUTPUT in compression. Normally expressed in units of %RO.

– The change in OUTPUT due to a change in AMBIENT TEMPERATURE. Normally expressed as the slope of a chord spanning the COMPENSATED TEMPERATURE RANGE and in units of %/°F or %/100°F.

– The change in ZERO BALANCE due to a change in AMBIENT TEMPERATURE. Normally expressed as the slope of a chord spanning the COMPENSATED TEMPERATURE RANGE and in units of %RO/°F or %RO/100°F.

– The range of temperature over which the LOAD CELL is compensated to maintain OUTPUT and ZERO BALANCE within specified limits.

– The extremes of AMBIENT TEMPERATURE within which the LOAD CELL will operate without permanent adverse change to any of its performance characteristics.

– Another name for ZERO FLOAT.

– The SIGNAL of the LOAD CELL in the NO LOAD condition.

– Another name for ZERO FLOAT.

– The shift in ZERO BALANCE resulting from a complete cycle of equal tension and compression loads. Normally expressed in units of %FS and usually characterized at FS = CAPACITY.

– The degree to which ZERO BALANCE is maintained over a specified period of time with all environmental conditions, loading history, and other variables remaining constant.

– force applied in one direction, tension or compression, from 0 to 100, constant for an extended period of time

– loads that vary in both force and direction

– multiple cycles, 100% compression to 100% tension load

– a mechanical solution that protects a load cell from exceeding forces

– used to modify the signal to the type of output required, including;4-20mA, ±5V, ±10V, 0-5V, and 0-10V

– a load cell with electronic identification inside, including sensor information and calibration data

Interface offers a complete line of instrumentation to provide you with exactly the information you need, including: indicators, signal conditioners and PC interface modules with USB and software options.

The creation of this instructional guide, Interface Load Cell Field Guide, was driven by a statement in Interface’s mission to always go above and beyond. We believe this informative reference is a helpful resource from the company that is recognized as pioneers in force measurement and load cell design and manufacturing. Our team of the most innovative load cell engineer’s best understand their design, capabilities, multitude of uses, and capacities. They are eager to share their knowledge and collective expertise to help other engineers and designers with load cell fundamentals to help make better force measurement decisions.

Interface’s Load Cell Field Guide was first published in 2014. As a result, we have heard how much the book helps fellow engineers around the world learn about the intricacies of load cell design and about some of the many applications of load cells in force measurement. In our new edition, we updated essential information to provide more value to load cell users and force measurement enthusiasts.

Interface has been designing and manufacturing load cells since our founding in 1968. We are extremely proud of our history and our products. As we move into our 2nd 50, we continue our commitment to provide the absolute best in force measurement solutions.

We know our customers rely on our products to make their products perform at their best. Our purpose is to enable innovation across all industries. Innovation that improves people’s lives and keeps them safe.

This means quality in products and production are cornerstones for our business. Interface is an integrated manufacturing operation. Whether we are making standard off the shelf Interface LowProfile load cells, modified minis, or our custom designed torque or wireless solutions, we control the process from the initial customer quote until the products ship out the door. We believe that beyond a great design, the process and control of the process are what enables a load cell to have the accuracy and dependability of an Interface Load Cell.

The load cell starts in our factory as a raw piece of steel, aluminum, or other metal that is then machined, gaged, wired, finished, and finally calibrated. As you can understand from this book, strain gages are what make a load cell a load cell. How they are made and how they are handled is critical to the operation and accuracy of a load cell. That is why we chose to be one of the only load cell companies in the world that manufactures its own strain gages. This guide is also available on Amazon, if you prefer the printed copy.

Frequently, customers want to use a load cell as an element in the physical structure of a machine or assembly. Therefore, they would like to know how the cell would react to the forces developed during the assembly and operation of the machine.

For the other parts of such a machine, made from stock materials, the designer can look up their physical characteristics (such as thermal expansion, hardness, and stiffness) in handbooks and determine the interactions of his parts based on his design. However, since a load cell is built on a flexure, which is a complex machined part whose details are unknown to the customer, its reaction to forces will be difficult for the customer to determine.

It is a useful exercise to consider how a simple flexure responds to loads applied in different directions. Figure 14 shows examples of a simple flexure, made by grinding a cylindrical groove into both sides of a piece of steel stock. Variations of this idea are used extensively in machines and test stands to isolate load cells from side loads. In this example, the simple flexure represents a member in a machine design, not an actual load cell.

The thin section of the simple flexure acts as a virtual frictionless bearing having a small rotational spring constant. Therefore, the spring constant of the material may have to be measured and factored into the response characteristics of the machine.

If we apply a tensile force, Fn or a compressive force, Fe, to the flexure at an angle off of its centerline, the flexure will be distorted sideways by the vector component, FTX or Fex, as shown by the dotted outline. Although the results looks quite similar for both cases, they are drastically different.

In the tensiIe case in Figure 14, the flexure tends to bend into alignment with the off-axis force and the flexure assumes an equilibrium position safely, even under considerable tension.

In the compressive case, the flexure’s reaction, as shown in Figure 15, can be highly destructive, even though the applied force is exactly the same magnitude and is applied along the same line of action as the tensile force, because the flexure bends away from the line of action of the applied force. This tends to increase the side force, F’ex, with the result that the flexure bends even more. If the side force exceeds the ability of the flexure to resist the turning motion, the flexure will continue to bend and will ultimately fail. Thus, the failure mode in compression is bending collapse, and will occur at a much lower force than can be safely applied in tension.

The lesson to be learned from this example is that extreme caution must be applied when designing compressive load cell applications using columnar structures. Slight misalignments can be magnified by the motion of the column under compressive loading, and the result can range from measurement errors to complete failure of the structure.

The previous example demonstrates one of the major advantages of the Interface Low Profile cell design. Since the cell is so short in relation to its diameter, it does not behave like a column cell under compressive loading. It is much more tolerant of misaligned loading than a column cell.

The stiffness of any load cell along its primary axis, the normal measurement axis, can be calculated easily, given the rated capacity of the cell and its deflection at rated load. Load cell deflection data can be found in the Interface Catalog.

Keep in mind that these values are typical, but are not controlled specifications for the load cells. In general, the deflections are characteristics of the flexure design, the flexure material, the gage factors and the final calibration of the cell. These parameters are each individually controlled, but the cumulative effect may have some variability.

Using the SSM-100 flexure in Figure 16 as an example, the stiffness in the “Z” direction (the primary axis) can be calculated as follows:

Where:

Stiffness on primary axis

Rated Capacity

Deflection at Rated Output

For the SSM-100:

This type of calculation is true for any linear load cell on its primary axis. In contrast, the stiffnesses of the “Xli and “Y” axes are much more complicated to determine theoretically, and they are not usually of interest for users of Mini Cells, for the simple reason that the response of the cells on those two axes is not controlled as it is for the Low Profile series. For Mini Cells, it is always advisable to avoid the application of side loads as much as possible, because the coupling of off-axis loads into the primary axis output can introduce errors into the measurements.

For example, application of the side load, Fx, causes the gages at “AI! to see tension, and the gages at “B” to see compression. If the flexures at “A” and liB” were identical and the gage factors of the gages at “A” and liBII were matched, we would expect the output of the cell to cancel the effect of the side load. However, since the SSM series is a low-cost utility cell which is typically used in applications having low side loads, the extra cost to the customer of balancing out the side load sensitivity is usually not justifiable.

The correct solution where side loads or moment loads may occur is to uncouple the load cell from those extraneous forces by the use of a rod end bearing at one or both of the ends of the load cell.

For example, Figure 17 shows a typical load cell installation for weight of a barrel of fuel sitting on a weigh pan, in order to weigh the fuel used in engine tests.

A clevis is mounted firmly to the support beam by its stud. The rod end bearing is free to rotate around the axis of its support pin, and can also move about ±10 degrees in rotation both in and out of the page and around the primary axis of the load cell. These freedoms of motion ensure that the tension load stays on the same centerline as the load cell’s primary axis even if the load is not properly centered on the weigh pan.

Note that the nameplate on the load cell reads upside down, because the dead end of the cell must be mounted to the support end of the system.

Frequently, a load cell will be used in a situation where a light load, such as a weigh pan or small test fixture will be attached to the live end of the cell. The user would like to know how quickly the cell will respond to a change in loading. By connecting the output of a load cell to an oscilloscope and running a simple test, we can learn some facts about the dynamic response of the cell. If we firmly mount the cell on a massive block and then tap the cell’s active end very lightly with a tiny hammer, we will see a damped sine wave train (a series of sine waves which progressively decrease to zero).

Use extreme caution when applying impact to a load cell. The force levels can damage the cell, even for very short intervals.

The frequency (number of cycles occurring in one second) of the vibration can be determined by measuring the time (T) of one complete cycle, from one positive-going zero crossing to the next. One cycle is indicated on the oscilloscope picture in Figure 18 by the bold trace line. Knowing the period (time for one cycle), we can calculate “fo” (the natural frequency of free oscillation of the load cell) from the formula:

Where:

natural frequency

time for one cycle

The natural frequency of a load cell is of interest, because we can use its value to estimate the dynamic response of the load cell in a lightly loaded system.

Natural frequencies are typical values, but are not a controlled specification. They are given in the Interface catalog only as an assistance to the user.

The equivalent spring-mass system of a load cell is shown in Figure 190 The mass, mb corresponds to the mass of the live end of the cell, from the attachment point to the thin sections of the flexure. The spring, having spring constant K, represents the spring rate of the thin measurement section of the flexure. The mass, m2, represents the added mass of any fixtures which are attached to the live end of the load cell.

Figure 20 relates these theoretical masses to the actual masses in a real load cell system. Note that the spring constant, K, occurs on the dividing line at the thin section of the flexure.

Natural frequency is a basic parameter, the result of the design of the load cell, so the user must understand that the addition of any mass on the active end of the load cell will have the effect of lowering the total system’s natural frequency. For example, we can imagine pulling down slightly on the mass m1, in Figure 19, and then letting go. The mass will oscillate up and down at a frequency determined by the spring constant, K, and the mass of m1. In fact, the oscillations will damp out as time progresses in much the same way as in Figure 18.

If we now bolt the mass m2 on m1, the increased mass loading will lower the natural frequency of the spring-mass system. Fortunately, if we know the masses of m1 and m2, and the natural frequency of the original spring-mass combination, we can calculate the amount that the natural frequency will be lowered by the addition of m2, according to the formula:

Where:

system natural frequency

load cell natural frequency

load cell live end mass

added fixture mass

To an electrical or electronic engineer, the static calibration is a “DC” parameter, whereas the dynamic response is an “AC” parameter. This is represented in Figure 21, where the DC calibration is shown on the factory calibration certificate, and users would like to know what the response of the cell will be at some driving frequency they will be using in their tests.

Note the equal spacing of the “Frequency” and “Output” grid lines on the graph in Figure 21. Both of these are logarithmic functions; that is, they represent a factor of 10 from one grid line to the next. For example, “0 db” means “no change”; “+20 db” means “10 times as much as 0 db”; “–20 db” means “1/10 as much as 0 db”; “–40 db” means “1/100 as much as “0 db.”

By using logarithmic scaling, we can show a larger range of values, and the more common characteristics turn out to be straight lines on the graph. For example, the dashed line shows the general slope of the response curve above the natural frequency. If we continued the graph down and off to the right, the response would become asymptotic (closer and closer) to the dashed straight line.

The curve in Figure 21 is provided only to portray the typical response of a lightly loaded load cell under optimum conditions. In most installations, the resonances in the attaching fixtures, test frame, driving mechanism and UUT (unit under test) will predominate over the load cell’s response.

In cases where the load cell is mechanically tightly coupled into a system where the masses of the components are significantly heavier than the load cell’s own mass, the load cell tends more to act like a simple spring which connects the driving element to the driven element in the system.

The problem for the system designer becomes one of analyzing the masses in the system and their interaction with the very stiff spring constant of the load cell. There is no direct correlation between the load cell’s unloaded natural frequency and the heavily loaded resonances which will be seen in the user’s system.

Almost everyone has bounced a basketball and noticed that the period (time between cycles) is shorter when the ball is bounced closer to the floor. Anyone who has played a pinball machine has seen the ball rattling back and forth between two of the metal posts; the closer the posts get to the diameter of the ball, the faster the ball will rattle. Both of these resonance effects are driven by the same elements: a mass, a free gap, and a springy contact which reverses the direction of travel.

The frequency of oscillation is proportional to the stiffness of the restoring force, and inversely proportional both to the size of the gap and to the mass. This same resonance effect can be found in many machines, and the buildup of oscillations can damage the machine during normal operation.

For example, in Figure 23 a dynamometer is used to measure the horsepower of a gasoline engine. The engine under test drives a water brake whose output shaft is connected to a radius arm. The arm is free to rotate, but is constrained by the load cell. Knowing the RPM of the engine, the force on the load cell, and the length of the radius arm, we can calculate the horsepower of the engine.

If we look at the detail of the clearance between the ball of the rod end bearing and the sleeve of the rod end bearing in Figure 23, we will find a clearance dimension, liD,” because of the difference in size of the ball and its constraining sleeve. The sum of the two ball clearances, plus any other looseness in the system, will be the total IIgapII which can cause a contact resonance with the mass of the radius arm and the spring rate of the load cell.

As the engine speed is increased, we may find a certain RPM at which the rate of firing of the engine’s cylinders matches the contact resonance frequency of the dynamometer. If we hold that RPM, magnification (multiplication of the forces) will occur, a contact oscillation will build up, and impact forces of ten or more times the average force could easily be imposed on the load cell.

This effect will be more pronounced when testing a one-cylinder lawn mower engine than when testing an eight cylinder auto engine, because the firing impulses are smoothed out as they overlap in the auto engine. In general, raising the resonant frequency will improve the dynamic response of the dynamometer.

The effect of contact resonance can be minimized by:

Any transducer which depends upon the deflection of a metal for its operation, such as a load cell, torque transducer or pressure transducer, retains a history of its previous loadings. This effect occurs because the minute motions of the crystalline structure of the metal, small as they are, actually have a frictional component which shows up as hysteresis (non-repeating of measurements which are taken from different directions).

Prior to the calibration run, the history can be swept out of the load cell by the application of three loadings, from zero to a load which exceeds the highest load in the calibration run. Usually, at least one load of 1300/0 to 140% of the Rated Capacity is applied, to allow the proper setting and jamming of the test fixtures into the load cell.

If the load cell is conditioned and the loadings are properly done, a curve having the characteristics of A-B-C-D-E-F-G-H-I-J-A, as in Figure 24, will be obtained. The points will all fall onto a smooth curve, and the curve will be closed on the return to zero. Furthermore, if the test is repeated and the loadings are properly done, the corresponding points between the first and second runs will fall very close to each other, demonstrating the repeatability of the measurements.

Whenever a calibration run yields results which don’t have a smooth curve, don’t repeat well, or don’t return to zero, the test setup or loading procedure should be the first place to check.

For example, Figure 24 shows the result of the application of loads where the operator was not careful when the 60% load was applied. If the weight was dropped slightly onto the loading rack and applied an impact of 80% load and then returned to the 600/0 point, the load cell would be operating on a minor hysteresis loop which would end up at point “P” instead of at point “D.” Continuing the test, the 80% point would end up at “R,” and the 1000/0 point would end up at “S.” The descending points would all fall above the correct points, and the return to zero would not be closed.

The same type of error can occur on a hydraulic test frame if the operator overshoots the correct setting and then leaks back the pressure to the correct point. The only recourse for impacting or overshooting is to recondition the cell and start the test over.

Load cells are routinely conditioned in one mode (either tension or compression), and then calibrated in that mode. If a calibration in the opposite mode is also required, the cell is first conditioned in that mode prior to the second calibration. Thus, the calibration data reflects the operation of the cell only when it is conditioned in the mode in question.

For this reason, it is important to determine the test protocol (the sequence of load applications) which the customer is planning to use, before a rational discussion of the possible sources of error can occur. In many cases, a special factory acceptance must be devised to ensure that the user’s requirements will be met.

For very stringent applications, users are generally able to correct their test data for the nonlinearity of the load cell, thus removing a substantial amount of the total error. If they are unable to do so, nonlinearity will be part of their error budget.

Nonrepeatability is essentially a function of the resolution and stability of the user’s signal conditioning electronics. Load cells typically have nonrepeatability which is better than the load frames, fixtures and electronics used to measure it.

The remaining source of error, hysteresis, is highly dependent on the loading sequence in the user’s test protocol. In many cases, it is possible to optimize the test protocol so as to minimize the introduction of unwanted hysteresis into the measurements.

However, there are cases where users are constrained, either by an external customer requirement or by an internal product specification, to operate a load cell in an undefined way which will result in unknown hysteresis effects. In this event, the user will have to accept the worst case hysteresis as an operating specification.

Also, some cells must be operated in both modes (tension and compression) during their normal use cycle without being able to recondition the cell before changing modes. This results in a condition called toggle . (non-return to zero after looping through both modes). In normal factory output, the magnitude of toggle is a broad range where the worst case is approximately equal to or ~light1y larger than hysteresis, depending on the load cell’s flexure material and capacity.

Fortunately, there are several solutions to the toggle problem:

All on-axis loadings generate some level, no matter how small, of off-axis extraneous components. The amount of this extraneous loading is a function of the tolerancing of the parts in the design of the machine or load frame, the precision with which the components are manufactured, the care with which the elements of the machine are aligned during assembly, the rigidity of the load-bearing parts, and the adequacy of the attaching hardware.

The user can opt to design the system so as to eliminate or reduce off-axis loading on the load cells, even if the structure suffers distortion under load. In tension mode, this is possible by the use of rod end bearings with clevises.

Where the load cell can be kept separate from the structure of the test frame, it can be used in compression mode, which almost eliminates the application of off axis load components to the cell. However, in no case can off-axis loads be completely eliminated, because the deflection of load carrying members will always occur, and there will always be a certain amount of friction between the load button and the loading plate which can transmit side loads into the cell.

When in doubt, the Low Profile cell will always be the cell of choice unless the overall system error budget allows a generous margin for extraneous loads.

In high-precision test applications, a rigid structure with low extraneous loading can be achieved by the use of ground flexures to build the measurement frame. Of course, this requires precision machining and assembly of the frame, at considerable cost.

One serious effect of off-axis loading is the reduction of the cell’s overload capacity. The typical 150% overload rating on a standard load cell or the 300% overload rating on a fatigue-rated cell is the allowed load on the primary axis, without any side loads, moments or torques applied to the cell concurrently. This is because the off-axis vectors will add with the on-axis load vector, and the vector sum can cause an overload condition in one or more of the gaged areas in the flexure.

To find the allowed on-axis overload capacity when the extraneous loads are known, compute the on-axis component of the extraneous loads and algebraically subtract them from the rated overload capacity, being careful to keep in mind in which mode (tension or compression) the cell is being loaded.

Neophytes in the use of load cells frequently destroy one before an old-timer has a chance to warn them about impact loads. We would all wish that a load cell could absorb at least a very short impact without damage, but the reality is that, if the live end of the cell moves more than 150% of the full capacity deflection in relation to the dead end, the cell could be overloaded, no matter how short the interval over which the overload occurs.

In Panel 1 of the example in Figure 24, a steel ball of mass “m” is dropped from height “S” onto the live end of the load cell. During the fall, the ball is accelerated by gravity and has achieved a velocity “v” by the instant it makes contact with the surface of the cell.

In Panel 2, the velocity of the ball will be completely stopped, and in Panel 3 the direction of the ball will be reversed. All this must happen in the distance it takes for the load cell to reach the rated overload capacity, or the cell may be damaged.

In the example shown, we have picked a cell which can deflect a maximum of 0.002” before being overloaded. In order for the ball to be completely stopped in such a short distance, the cell must exert a tremendous force on the ball. If the ball weighs one pound and it is dropped one foot onto the cell, the graph of Figure 26 tells us that the cell will receive an impact of 6,000 lbf (It is assumed that the mass of the ball is much larger than the mass of the live end of the load cell, which is usually the case.)

The scaling of the graph can be modified mentally by keeping in mind that the impact varies directly with the mass and with the square of the distance dropped.

Load cells are constructed using electric resistance metal foil strain gages bonded to an elastic flexure element. The load cell is a passive analog device with continuous resolution limited ultimately by noise, due to electron motion on the order of 10-9 volts (1 nanovolt). Therefore, practically speaking, resolution is limited by the type and quality of the electronic instrumentation used, rather than by the load cell itself. Many reasonably priced instruments can resolve 0.8 to 1.0 microvolt/count as a minimum signal level.

For example, consider a load cell with Rated Output of 3mV/V. Assume that 10VDC excitation is used. At Rated Output, the signal level produced would be:

3mV/V x 10V = 30 mV

If the indicating instrument can resolve 1 microvolt in the rightmost digit of the display, then:

Resolution = 1 µvolt/30 mV

= 1 µvolt/30,000 µvolt

= 0.000033, fraction of Rated Output

= 0.0033 % of Rated Output

If, for example, an MB-5 (5 lbf Rated Capacity) load cell were being used, the resolution in pounds could be calculated as:

Resolution = 5 lbf x 0.000033

= 0.00017 lbf

If an instrument capable of 0.5 microvolt resolution were used, the resolution would be approximately 1 part in 60,000 or 0.000083 pounds for the 5 pound capacity cell. Maximum resolution may be limited by the instrument to the total number of counts that can be displayed.

Another typical example would be the case where only a portion of the range of the load cell is to be used. If the maximum load on the MB-5 were to be 3 pounds, then the output would be:

3 mV/V x 3 lbf / 5 lbf = 1.8 mV/V

Using 10V excitation provides a signal of 18 mV output for 3 pounds input. If the instrument displays is to display 30,000 counts a signal strength of

18 mV / 30,000 counts = 0.6 microvolt/count

results in a display of 0.00015 pound/count resolution. Of course, the instrument must have a sensitivity of at least 0.6 µvolt/count for this example.

It can be seen from the above examples that the sensitivity and stability of the electronic instrumentation is critical, when high resolution is required. High electronic gain alone will not achieve good results if the zero stability or gain stability is poor because the readings will drift with time or temperature changes.

Also, keep in mind that excessive resolution can be detrimental in situations where the stability of the applied force is low, as in some hydraulic systems.

Generally, it is desired to read physical units instead of counts. Most instruments provide a count-by feature of 1, 2, 5 or 10 to facilitate this. For the above example, an instrument could be set up to read 30,000 counts by 2 for the 3 pound load, providing resolution of 0.0002 lbf Premium instruments are available that offer as good as 0.001µvolt/count.

We have capacities ranging from 1 lbf / 500 gf to 2 million lbf / 9,000 kN. Our facility produces them in several shapes and sizes. Models include pancake load cell and donut load cell in our LowProfile® load cell and thru-hole load cell. Additionally, our canister, rod end, downhole, column, coil tubing, load buttons, and load washers all use our proprietary alloy strain gages. This helps us produce the most accurate and reliable data possible in test and measurment. With the wide variety of load cell specs in stock, most customers are able to use an off-the-shelf application. However, our engineers can also work with you to design a custom load cell to fit your exact needs. Contact us so that we can help you find a solution that fits your requirements.

The testing of materials and complex assemblies is such a vast field that it is impossible to cover all aspects of it completely in this manual. In this section, we will give an overview of the different types of material tests and other specialized tests using force as a variable, with some examples of the most common applications.

In the determination of the force versus deflection characteristics of a raw material, a fabricated part, or an assembly, it is usually necessary to control the position and orientation of the UUT (Unit Under Test), to control the direction and magnitude of the applied force, to measure one or more displacements, and to measure any other parameter which may vary with the force or displacement. For these reasons, a large market has developed over the years for sophisticated testing machines and their associated fixtures, transducers, and signal conditioning and recording equipment.

In the typical materials testing machine shown in Figure 42, where the clamp is shown, various other fixtures can be attached to hold, or even rotate, the UUT during the test. Other transducers can be mounted to measure torque, angle, pressure or any parameter the customer is willing to pay for. It is not unusual to test for torque and linear force concurrently, and the Interface Low Profile cells are eminently suited for this because of their high rejection of extraneous loads.

With the hydraulic ram at a solid stop, the gear drive can be servo-controlled to advance the displacement at a very accurately controlled rate, to determine the time dependency of a material’s characteristics. Or, with the gear drive locked, the hydraulic ram can apply a precise force profile, as controlled by the load cell.

In general, any modern test machine is programmed and controlled by its own internal microprocessor, with facilities for accepting large volumes of control information and transmitting high rates of measured data either to a local datalogger or to a network server for further processing.

In the determination of shear strength versus compaction of soils or construction materials, the object is to determine the shear strength as the material is used at different depths underground or at different levels in the construction of a high-rise building. Usually, a special test block is designed to test a particular type of material in conformance with a specification.

The test block is designed with a rectangular hole going through it, into which the tested material is inserted. To set up for the test, the shear block is put into position in the test block so that the hole in the shear block lines up with the rectangular test hole. The material under test is then packed into the hole, up through the hole in the shear block, and almost to the top of the test block. Finally, the compaction piston is inserted, and the material is evenly pressed down to fill the hole and remove air pockets and voids.

The actual test is performed in a test frame much like a materials test machine, except that it has an additional capability to pull out the shear block while measuring the shear force and shear deflection. To perform the test, the compaction force is first applied on the top of the compaction piston by a compression load cell, and then the tension shear force is applied to the shear block by another load cell. The test is repeated for a range of compaction forces, and the output from the test is a table of figures or a graph of shear force versus compaction force.

A common test for adhesives, adhesive-coated tapes, and paints is the peel test.

The test parameters are usually detailed in a government or industry specification, and the rate of pull is most often closely controlled. Adhesive-backed tapes are tested this way. Also, paint adhesion is tested by applying the paint according to instructions, applying a specified adhesive-backed tape to the painted surface, and then pulling the tape off in a specified way.

There are literally thousands of adhesives and bonding agents which are used to assemble parts into assemblies. In addition to their bonding characteristics, they may be required to have a certain elasticity, resistance to chemicals, electrical conductivity, temperature coefficient, or other controlled parameter.

In addition to the general-purpose shear test machines on the market, many testers are designed and constructed in-house to perform specific tests on unique assemblies.

The design of a shear tester is relatively straightforward, as long as the following conditions are met:

Many industry and government specifications require testing the components of a system at many times the rated or nameplate loading, where the failure of the component could result in costly damage to equipment or injury to personnel.

The most sensitive product liability area for load cell manufacturers is the use of a load cell in tension on a crane which lifts loads where it is possible that a person could be under the load, even by mistake. Proof testing in this case usually requires that the equipment be proof tested at five times its rating. Obviously, a tension load cell could never survive such a test. Interface never recommends using a tension load cell in this type of application.

The most straightforward solution, where it is necessary to measure the load in a tension cable subject to safety considerations is to enclose the load cell in a compression cage, which converts tension into compression. The compression cell is trapped between the two plates. Thus, the load cell’s only overload failure mode is in compression, which allows a motion of only 0.001” to 0.010” before the load cell becomes solid. Even if the load cell is totally destroyed, the compression cage cannot drop the load unless it fails itself. Therefore, the cage can be proof tested with a dummy load cell, or an overload protected cell, and the risk of injury to personnel is avoided.

One of the critical tests on missile assemblies is the determination of the center of gravity, because variations in the weight distribution in a missile can have a disastrous effect on its flight stability.

The test stand shown in Figure 47 typifies the elements which need to be addressed to optimize the test.

The designer who promotes a three-cell system may meet with some opposition from engineers whose minds are used to working in an orthogonal (right angled) reference system. However, the mechanical headaches associated with the shimming of a four-cell system and readjusting it when the temperature varies are worth the extra effort to solve the equations for a triangular system.

For example, if the CG (center of gravity) is supposed to be at the exact center of the triangular pattern of the load cells, the diagram in Figure 48 shows the load cells at ~ B, and C all measuring exactly the same loads cx, P, and y. When those load vectors are plotted as distances from their respective opposite sides (which are the fulcrums against which the vectors operate), we find that they coincide at the CG, at the exact centroid of the triangular load cell pattern.

This means that the CG is exactly where it should be, and it also gives us fair assurance that the system has been properly calibrated.

However, if the CG is mislocated in the missile, as in Figure 49, the vectors will define a different set of distances from their respective fulcrums. When we measure the vector cx from the baseline BC, we construct line be parallel to the baseline BC. In the same manner, we construct line ae at distance from baseline AC. The intersection of lines ae and be defines the CG point.

The question then arises, “How did we find the CG without using line ab?” The answer is, “Any two of the lines could define the CG, because the data from all three cells was used to define the two lines, and the intersection of two lines defines a point. “

The position of the third line is a redundant check, and is a nice way of checking the accuracy of the measurement. If the third line (whichever one we choose) does not go through the same point as the intersection of the first two lines, we need to check our test system and find the error, because all three lines should agree on the location of the eG. In Figure 49, the CG is mislocated, but all three lines agree on the intersection point. Thus, the test is good, but the CG is mislocated in the missile.

In most applications it is difficult, if not impossible, to calculate or even estimate the effect of misalignments on the precision of a force measurement system. Moment sensitivity introduces errors into force measurements whenever forces cannot be applied precisely on-axis.

The Interface Low Profile design provides optimum resistance to extraneous loads to insure maximum operation life and minimize reading errors. The above chart tabulates maximum allowable extraneous loads that may be applied singularly without electrical or mechanical damage to the cell and the maximum error that can be expected from side forces or bending moments. Several loads can be tolerated simultaneously if the total combined load is not more than 100% of the allowable maximum extraneous load.

Only Interface guarantees maximum extraneous load error and physically adjusts every load cell. The Interface 1200 Series cells have eccentric load sensitivity less than ±0.25% of reading per inch, and the 1000, 1100, and 1600 Series are further adjusted to come in at less than ±0.1% of reading per inch. Most competing load cells will have extraneous load error 10 times higher (or even more) than with a superior Interface load cell.

Compression cells are widely used for weighing applications because they are less expensive and in some cases have slightly lower errors. Figure 27 shows a typical application. The load cell with base is mounted on the stud which is permanently affixed in the bottom plate. This gives the cell added protection against any uneven surface under the bottom plate which might affect the calibration of the cell.

The load cell’s load button is hard anodized or heat treated to ensure a hard surface. The load bearing surface of the top plate must be heat treated to increase its hardness. Cold rolled steel or similar material is not appropriate, because the surface will soon gall and become useless. Also, the finish of both the top plate’s bearing surface and load cell’s load button should have 32 µinch or smoother surface roughness to ensure that galling will not occur.

The configuration of Figure 27 is widely used because the cell with base can be removed as a complete assembly by screwing it off of the bottom plate’s stud. When it is replaced, the original factory calibration of the new cell can be preserved, because the base protects the load cell against any unevenness in the surface facing the bottom of the base.

The configuration of Figure 28 is used in situations where the bottom surface of the hopper leg which bears on the load cell/bottom plate assembly can be machined flat and smooth. This allows the load cell to be mounted directly on the bottom plate, without an intervening base, thus saving the cost of a base. Although conceptually simpler, this configuration requires that the bottom plate be installed at the factory so that the assembly can be calibrated. This configuration also protects the diaphragm surface of the load cell from being subjected to standing water in installations having water misting or splashing.

The majority of compression cell applications are multiple-cell installations. The number of cells may run anywhere from 3 cells on a simple weighing platform to 16 cells on a long truck scale.

In every case, the accuracy and repeatability of the system will be improved by following these simple rules:

When designing the mechanical mounting of the cells in a multiple-cell system, provisions should be made for the leveling adjustment necessary to equalize the loading of the cells among all the “corners” of the system. (In this context, all the cells in a multicell system are called “comers,” even though some of them may be on sides, between corners.) It is advantageous that all the cells operate at the same point on their operating curves, by being equally loaded, in order to achieve maximum system accuracy.

Everyone has had the experience of sitting on a four-legged chair which has one slightly short leg, and getting the feeling of rocking back and forth with one or the other leg always off the floor. Although we think that our weight is being carried by three of the four legs, in truth almost our whole weight is sometimes on only two of the legs. The same effect can be seen on a multiple-cell system which has been improperly shimmed.

In an improperly equalized four-cell system, it is possible that the total load could be carried momentarily by two diagonally opposite load cells, which would be almost certain to overload the cells.

The “rocking chair” effect will be more or less pronounced, depending on the stiffness of the framework or structure which transmits the load to the cells.

For example, we can construct a very stiff system by making a tank out of a thick-walled steel pipe four feet in diameter, with a flat bottom welded inside it part way up from the bottom, as in Figure 30. The bottom edge of the pipe is prepared by having hard inserts welded into it to match the locations of the load buttons on the load cells, and the inserts are carefully ground to a planar surface. The four load cells are mounted on a very thick, stiff steel plate which has been ground as flat as humanly possible.

As the pipe is slowly and carefully lowered onto the cells, we find to our dismay that two diagonally opposite cells are taking much more load than the other two cells. This is happening because the full scale deflection of the load cells is only a few thousandths of an inch, and it is too costly, if not impossible, to grind the surfaces of the plate and the tank that flat over such a large span to that close a tolerance.

If we had any intention of shimming the cells to equalize the loading, we would need to use shims that are only about 1/5 the thickness of a piece of paper. Such a task would take days to accomplish. In addition, distortion of the tank by temperature gradients (uneven changes in temperature) in the tank when the sun shines on it or when hot liquid is pumped into it would introduce dramatic changes in the careful job of shimming which we had just finished.

The important lesson to be learned from this example is that there needs to be some flexibility built into the design of the tank structure to make the shimming job easier and to reduce the effect on the cell loading caused by temperature gradients distorting the tank. Figure 31 simulates a springy system by actually picturing springs under the legs, which makes it easier to visualize how a springy frame alleviates the shimming problem.

We can now calculate the effect of the addition of a shim which is 0.002” thick. Let’s assume a 10,000 lbf load cell with a deflection of 0.002” at full capacity, which gives it a stiffness of 5 million pounds per inch.

In the “stiff” case of Figure 30, adding or removing one shim only 0.002” thick would change the load on that cell by 5,000 lbf. Thus, it would be very difficult to adjust the loading on the cell in increments of 5% of full capacity. (The reader is left with the problem of figuring out why the change in loading is only 1/2 of the “expected” value.)

Now, let’s assume that the springs in Figure 31 have been chosen to have a stiffness of 50,000 pounds per inch, 1/100th of the stiffness of the load cells. When we first lower the frame onto the cells, the springs will alleviate much of the uneven loading on the cells. In addition, as we check the cells’ outputs, we find that the addition of a shim of 0.002” thickness raises the loading on that cell by 50 Ibf, well within the equalization increment of 5% of full capacity which we were shooting for.

Equalizing a tension system is a much easier task than shimming a compression system. The load cells will all be moment protected, either by the use of rod end bearings and clevises or by using flexible cable assemblies on each cell. It is then necessary only to insert a turnbuckle in one of the supports on a four-cell system, two of the supports in a five-cell system, or three of the supports in a six-cell system. Since one-, two-, or three cell systems do not need physical shimming adjustment, they are obviously much easier to install, and are hardly affected by distortions due to temperature gradients in the support framework.

After the cells have all been equalized, an electrical comer adjustment will be needed on most systems unless it has already been done at the factory.

Do not change any adjustments on a system which has already been calibrated at the factory. The factory calibration will be lost.

Corner adjustment is accomplished as follows:

In the same way that a load cell can have moment sensitivity (output variation for off-axis loads), a weigh platform can respond differently for loads which are not exactly on the center of the platform. In the case of Figure 32, where the three load cells are equally spaced around the bolt circle with radius “R,” if the outputs of the cells are corner adjusted properly, the weight indication of the platform will be the same for any location of a test weight. This fact would seem to be intuitively true, simply because of the symmetry of the load cell layout.

But, when we propose the layout of Figure 33, the lack of rotational symmetry strains our intuition, and we may struggle with the concept that the only criterion for a successful weigh platform is that the cells are corner adjusted. However, strict mathematical analysis of either system yields the same answer: corner adjustment alone is sufficient.

There may be a functionally logical reason for the arrangement of Figure 33, or even Figure 34. In many cases, the load may be applied from a particular edge or a motor/gear assembly may be mounted off-center, and the concentration of cells closer together tends to distribute the load between the three cells more evenly.

The dimensions in Figure 34 are correct for an evenly loaded conveyor frame where the loads are dumped onto frame at the left end, on the line connecting the two cells. This arrangement gives more margin to protect the cells from overload. Incidentally, the load is equally divided among the cells when there is no product on the conveyor (tare condition) or the load is at the center mark of the conveyor.